Information injection-pump assembly

BOSCH

F 019 Z20 150

f019z20150

ZEXEL

106676-2463

1066762463

MITSUBISHI

ME442613

me442613

Rating:

Service parts 106676-2463 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

17.7(180)/21.6(220)

15.

NOZZLE SET

Include in #1:

106676-2463

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

F 019 Z20 150

f019z20150

ZEXEL

106676-2463

1066762463

MITSUBISHI

ME442613

me442613

Zexel num

Bosch num

Firm num

Name

106676-2463

F 019 Z20 150

ME442613 MITSUBISHI

INJECTION-PUMP ASSEMBLY

6D24TC K 14CA INJECTION PUMP ASSY PE6P,6PD PE

6D24TC K 14CA INJECTION PUMP ASSY PE6P,6PD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-4620

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.8

4.75

4.85

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

10.5

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

134

131

137

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

6.5+-0.5

Pump speed

r/min

425

425

425

Average injection quantity

mm3/st.

12.5

9.9

15.1

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

10.7++

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

145

145

155

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

1200++

Advance angle

deg.

0

0

0

Remarks

Do not advance until starting N = 1200.

Do not advance until starting N = 1200.

Timer adjustment_02

Pump speed

r/min

-

Advance angle

deg.

2

2

2

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

Test data Ex:

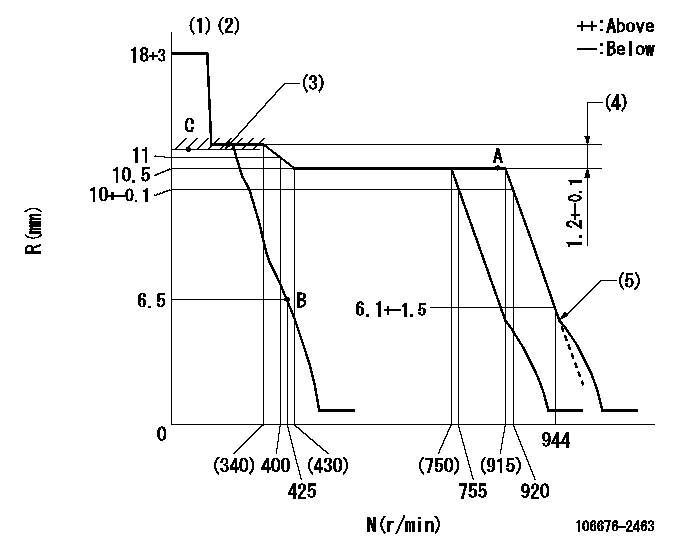

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Notch fixed: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Rack difference between N = N1 and N = N2

(5)Idle sub spring setting: L1.

----------

K=6 N1=900r/min N2=300r/min L1=4.7+-0.2mm

----------

----------

K=6 N1=900r/min N2=300r/min L1=4.7+-0.2mm

----------

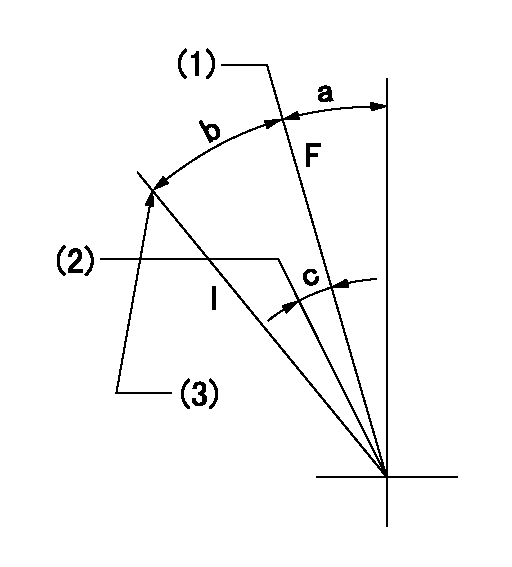

Speed control lever angle

F:Full speed

I:Idle

(1)Set the pump speed at aa. ( At delivery )

(2)When pump speed set at bb

(3)Stopper bolt setting

----------

aa=920r/min bb=755r/min

----------

a=(2deg)+-5deg b=(15.5deg)+-5deg c=(5deg)+-5deg

----------

aa=920r/min bb=755r/min

----------

a=(2deg)+-5deg b=(15.5deg)+-5deg c=(5deg)+-5deg

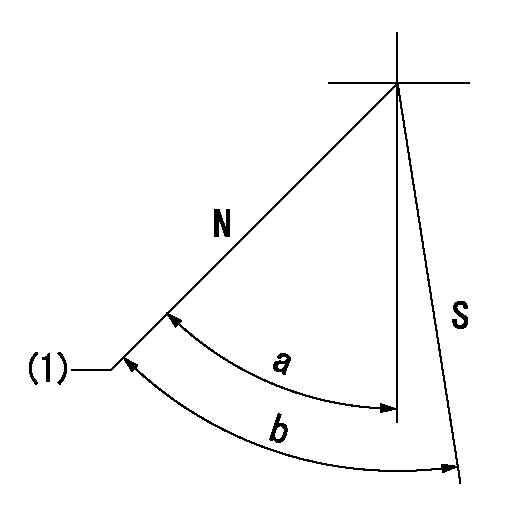

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Normal

----------

----------

a=43.5deg+-5deg b=53deg+-5deg

----------

----------

a=43.5deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=13deg

----------

a=(5deg)

----------

aa=13deg

----------

a=(5deg)

Information:

Image1

SERVICE CLAIM ALLOWANCES

Product smu/age whichever comes first Caterpillar Dealer Suggested Customer Suggested

Parts % Labor Hrs% Parts % Labor Hrs% Parts % Labor Hrs%

*******Group 1*******

0-500000 miles,

0-36 mo 100.0% 100.0% 0.0% 0.0% 0.0% 0.0%

This is a 6.0-hour job for Group 1

If the parts that are listed in the ACTION REQUIRED are on the engine, the engine has been previously updated and this Service Letter does not apply. Enter a claim against this service letter and charge 0.5 hours for the inspection time.

If the OEM CGI Flex line is replaced then it should be billed to your local OEM dealership as follows:

Cat Dealer Performs CGI Repair.

- Cat dealer purchases parts from Peterbilt / Kenworth dealer @ retail.

- Cat dealer performs repair (no charge to customer).

- Cat dealer files sublet invoice to Peterbilt / Kenworth dealer for parts (CAT will not increase part price to Peterbilt / Kenworth dealer) and labor reimbursement.

Invoice includes:

1) 17 digit VIN

2) Repair Order #

3) Vehicle mileage

4) Part pricing

5) Labor pricing

. Peterbilt / Kenworth dealer pays Cat dealer

. Peterbilt / Kenworth dealer files warranty claim (normal sublet) to Peterbilt / Kenworth

Peterbilt / Kenworth guarantees payment to Cat for the repairs performed.

Product smu/age whichever comes first Caterpillar Dealer Suggested Customer Suggested

Parts % Labor Hrs% Parts % Labor Hrs% Parts % Labor Hrs%

*******Group 2*******

0-500000 miles,

0-36 mo 100.0% 100.0% 0.0% 0.0% 0.0% 0.0%

This is a 6.0-hour job for Group 2

If the parts that are listed in the ACTION REQUIRED are on the engine, the engine has been previously updated and this Service Letter does not apply. Enter a claim against this service letter and charge 0.5 hours for the inspection time.

PARTS DISPOSITION

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

Rework Procedure

Step 1:

Follow instructions outlined in REHS4803.

Step 2:

Attach Data Log of successful regen and attach Air Systems Verification Test report to the Warranty report and add Technician's CWS or SSO ID in the Technicians Name field of the "Warranty Report - User Information screen. See example on page 2 of REHS4803.

NOTE 1:

The seating of the heater wire to the ARD head is critical. There have been some cases of the heater wire interfering with the ARD head and not allowing it to seat properly. Refer to Image 1.1.1 for an example of proper seating.

If the heater wire hex interferes with the ARD head, use a file on the heater wire hex to allow proper seating (Image 1.1.2). DO NOT USE any cleaner after removing material from the hex as it can cause a heater failure. Usually less than 2mm reduction is necessary if proper seating does not take place.

Image1.1.1

Image1.1.2

Have questions with 106676-2463?

Group cross 106676-2463 ZEXEL

Mitsubishi

Mitsubishi

Mitsubishi

Mitsubishi

106676-2463

F 019 Z20 150

ME442613

INJECTION-PUMP ASSEMBLY

6D24TC

6D24TC