Information injection-pump assembly

BOSCH

9 400 617 442

9400617442

ZEXEL

106676-2350

1066762350

MITSUBISHI

ME158862

me158862

Rating:

Cross reference number

BOSCH

9 400 617 442

9400617442

ZEXEL

106676-2350

1066762350

MITSUBISHI

ME158862

me158862

Zexel num

Bosch num

Firm num

Name

106676-2350

9 400 617 442

ME158862 MITSUBISHI

INJECTION-PUMP ASSEMBLY

6D24TC K 14CA INJECTION PUMP ASSY PE6P,6PD PE

6D24TC K 14CA INJECTION PUMP ASSY PE6P,6PD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-4620

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.8

4.75

4.85

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

9.2

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

165

162

168

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Boost pressure

kPa

33.3

33.3

Boost pressure

mmHg

250

250

Injection quantity adjustment_02

Adjusting point

B

Rack position

5+-0.5

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

8.5

5.9

11.1

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_03

Adjusting point

D

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

140

120

160

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Rack limit

*

Boost compensator adjustment

Pump speed

r/min

600

600

600

Rack position

R1-1.75

Boost pressure

kPa

4

2.7

5.3

Boost pressure

mmHg

30

20

40

Boost compensator adjustment_02

Pump speed

r/min

600

600

600

Rack position

R1(9.2)

Boost pressure

kPa

20

13.3

26.7

Boost pressure

mmHg

150

100

200

Timer adjustment

Pump speed

r/min

900

Remarks

Measure the actual advance angle.

Measure the actual advance angle.

Timer adjustment_02

Pump speed

r/min

-

Advance angle

deg.

2

2

2

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

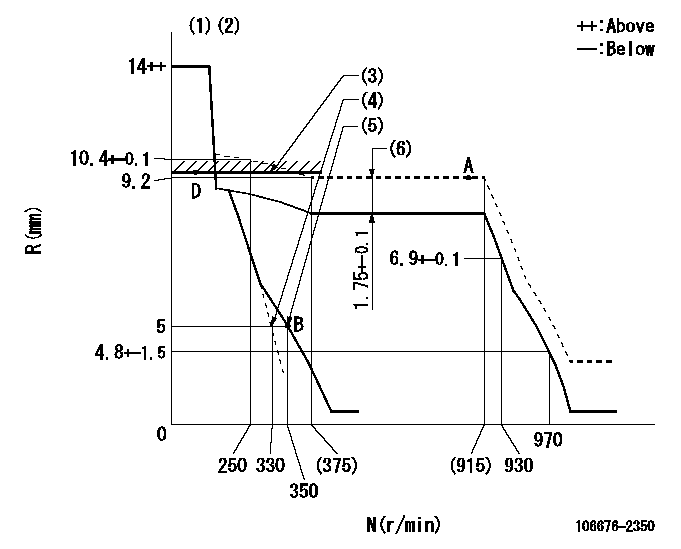

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Notch fixed: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Main spring setting

(5)Set idle sub-spring

(6)Boost compensator stroke

----------

K=10

----------

----------

K=10

----------

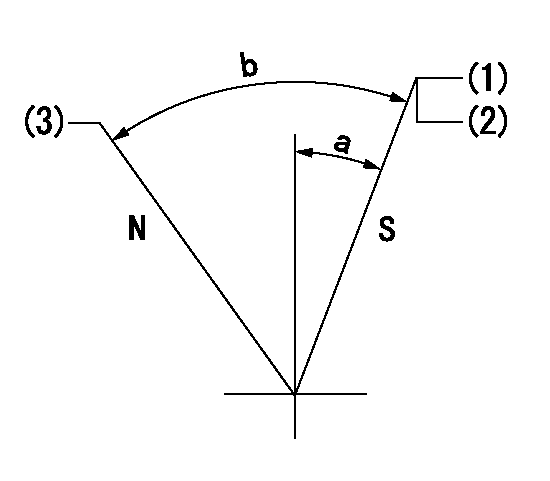

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=(18deg)+-5deg b=(2deg)+-5deg

----------

----------

a=(18deg)+-5deg b=(2deg)+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Pump speed aa and rack position bb (to be sealed at delivery)

(2)Stopper bolt setting

(3)Normal

----------

aa=0r/min bb=1-0.5mm

----------

a=35deg+-5deg b=70deg+-5deg

----------

aa=0r/min bb=1-0.5mm

----------

a=35deg+-5deg b=70deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=13deg

----------

a=(7deg)

----------

aa=13deg

----------

a=(7deg)

Information:

This is a 4.7-hour job for Group 1

Dealer to perform most economical repair.

Description______________SMCS CODE________Hours

Pump Replacement

Engine Wash______________1251-074_________0.3

R&I Pump ________________1251-010_________4.1

Minor Road Test__________1000-530_________0.3

Exception maybe considered and claimed depending on chassis type.

Caterpillar Dealer Suggested Customer Suggested

Parts % Labor Hrs% Parts % Labor Hrs% Parts % Labor Hrs%

100% 100% 0% 0% 0% 0%

This is a 0.6-hour job for Group 2

Dealer to perform most economical repair.

Option 1:

0.6 hours will be allowed to inspect the pump when the inspection determines pump serial number is not listed and pump replacement is not necessary.

Description______________SMCS CODE________Hours

Inspect Serial Number____1251-035_________0.6

Option 2 Pump Replacement:

4.7 Hours will be allowed to inspect and replace the pump when the inspection determines the pump serial number is listed and pump replacement is performed.

Description______________SMCS CODE________Hours

Engine Wash______________1251-074_________0.3

R&I Pump ________________1251-010_________4.1

Minor Road Test__________1000-530_________0.3

Exception maybe considered and claimed depending on chassis type.

PARTS DISPOSITION

***** U.S. and Canadian Dealers *****

Make sure the outside of the shipping

container is marked PIXXXX.

Return all Fuel Injection Pumps that are replaced and a copy of the

claim to:

Caterpillar Inc.

Attn: PIXXXXX

BUILDING DD DOCK 8

ROUTE 29 OLD GALENA ROAD

MOSSIVILLE, IL 61552

***** All Other Dealers *****

Handle the parts in accordance with your Warranty Bulletin on

warranty parts handling.

Attach. (1-Owner Notification)

MAKE EVERY EFFORT TO COMPLETE THIS PROGRAM AS SOON AS POSSIBLE.

IMPORTANT: SAFETY

SAFETY ? RECALL FOR REPLACING THE FUEL PUMP

MODELS INVOLVED - C7 and C9 Truck Engines

Dear Caterpillar Product Owner:

This notice is sent to you in accordance with the requirements of the National Traffic and Motor Vehicle Safety Act. This notice is also in accordance with the requirements of the Canadian Motor Vehicle Safety Act. Caterpillar has decided that a defect which relates to motor vehicle safety exists in trucks equipped with certain Caterpillar C7 & C9 engines.

A fuel pump failure will dilute the engine oil with fuel and may cause the turbocharger to fail and cause loss of throttle control and excessive smoke, both of which may result in a situation where a vehicle crash could occur. A new fuel pump will be installed on the engine. You will not be charged for the service performed.

If you are a lessor of these vehicles, you must forward this letter to your lessee within ten days.

If you have had your vehicle repaired prior to receipt of this notice and incurred any costs, you may be eligible for reimbursement. Please contact Caterpillar at this toll free number (800) 447-4986.

If you no longer own vehicle with this engine, please contact Caterpillar at this toll free number (800) 447-4986.

If the dealer is unable to have the repair made, please contact:

Caterpillar Inc.

PO Box 610

Mossville, IL 61552-610

Attn: Engine Products Division

Truck Engine Call Center

Telephone: (800) 447-4986

If you are unable to have the repair made within 60 days or without charge, you may submit a complaint to:

In the U.S.

Administrator

National Highway Traffic Safety Administration

1200 New Jersey Avenue, S.E.

Washington, D.C. 20590

Telephone: 1-888-327-4236 (TTY:1-800-424-9153)or go to http://www.safercar.gov

In Canada

Transport Canada

Road Safety and Motor Vehicle Regulation

Ottawa, Ontario KIA 0N5

Telephone: (613) 993-9851

Caterpillar Inc.

Contact your local Caterpillar dealer immediately to schedule this service. The dealer will advise you of the time required to complete this service. Please refer the dealer to their Service Letter dated -, 2007 when scheduling this service.

We

Have questions with 106676-2350?

Group cross 106676-2350 ZEXEL

Mitsubishi

Mitsubishi

Mitsubishi

Mitsubishi

106676-2350

9 400 617 442

ME158862

INJECTION-PUMP ASSEMBLY

6D24TC

6D24TC