Information injection-pump assembly

BOSCH

9 400 617 440

9400617440

ZEXEL

106676-2332

1066762332

MITSUBISHI

ME158828

me158828

Rating:

Service parts 106676-2332 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

17.7(180)/21.6(220)

15.

NOZZLE SET

Include in #1:

106676-2332

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 617 440

9400617440

ZEXEL

106676-2332

1066762332

MITSUBISHI

ME158828

me158828

Zexel num

Bosch num

Firm num

Name

9 400 617 440

ME158828 MITSUBISHI

INJECTION-PUMP ASSEMBLY

6D24-T * K 14CA INJECTION PUMP ASSY PE6P,6PD PE

6D24-T * K 14CA INJECTION PUMP ASSY PE6P,6PD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-4620

Overflow valve opening pressure

kPa

255

255

255

Overflow valve opening pressure

kgf/cm2

2.6

2.6

2.6

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.8

4.75

4.85

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

8.4

Pump speed

r/min

1000

1000

1000

Each cylinder's injection qty

mm3/st.

101.5

98.5

104.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

5.5+-0.5

Pump speed

r/min

350

350

350

Each cylinder's injection qty

mm3/st.

12

10.2

13.8

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(8.4)

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

101.5

99.5

103.5

Basic

*

Fixing the lever

*

Boost pressure

kPa

26.7

26.7

Boost pressure

mmHg

200

200

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+0.85

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

116

110

122

Fixing the lever

*

Boost pressure

kPa

26.7

26.7

Boost pressure

mmHg

200

200

Injection quantity adjustment_05

Adjusting point

D

Rack position

R2[R1+1]

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

117.5

109.9

125.1

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_06

Adjusting point

E

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

100

60

140

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

500

500

500

Rack position

R2[R1+1]

Boost pressure

kPa

7.3

6

8.6

Boost pressure

mmHg

55

45

65

Boost compensator adjustment_02

Pump speed

r/min

500

500

500

Rack position

(10)

Boost pressure

kPa

13.3

13.3

13.3

Boost pressure

mmHg

100

100

100

Timer adjustment

Pump speed

r/min

0

Advance angle

deg.

2.5

2

3

Timer adjustment_02

Pump speed

r/min

N1

Advance angle

deg.

2.5

2

3

Remarks

Measure speed (beginning of operation).

Measure speed (beginning of operation).

Timer adjustment_03

Pump speed

r/min

-

Advance angle

deg.

0

0

0

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

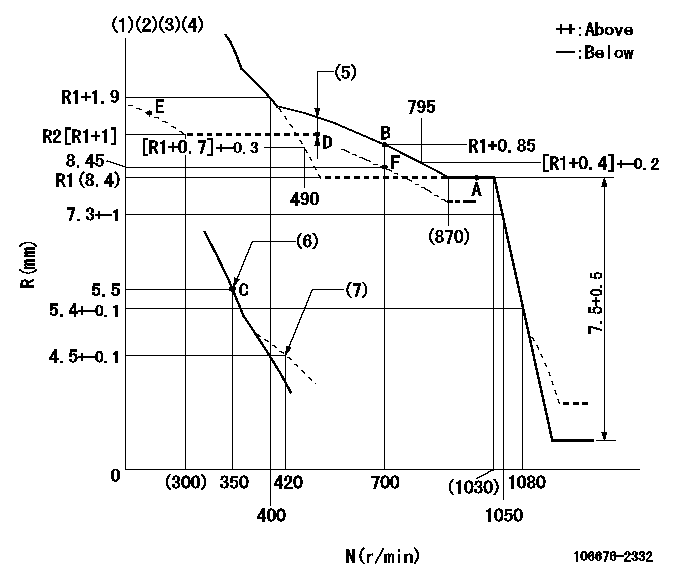

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Lever ratio: RT

(2)Target shim dimension: TH

(3)Boost compensator cancel stroke: BSL

(4)Tolerance for racks not indicated: +-0.05mm.

(5)Boost compensator stroke: BCL

(6)Main spring setting

(7)Damper spring setting

----------

RT=1 TH=1.9mm BSL=1.6mm BCL=(0.6)mm

----------

----------

RT=1 TH=1.9mm BSL=1.6mm BCL=(0.6)mm

----------

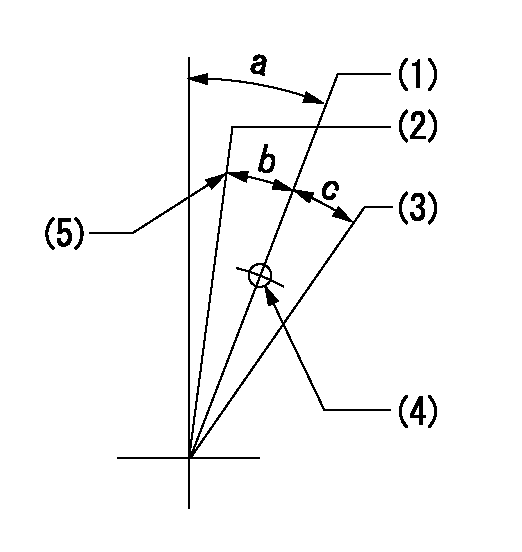

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=15.5deg+-5deg b=15deg+-5deg

----------

----------

a=15.5deg+-5deg b=15deg+-5deg

0000000901

(1)Normal full load

(2)Rack position = aa, speed = bb (half load)

(3)Lever cancel angle

(4)Use the hole above R = cc

(5)Stopper bolt setting

----------

aa=8.45mm bb=700r/min cc=75mm

----------

a=10deg+-5deg b=3deg+-3deg c=(11.5deg)

----------

aa=8.45mm bb=700r/min cc=75mm

----------

a=10deg+-5deg b=3deg+-3deg c=(11.5deg)

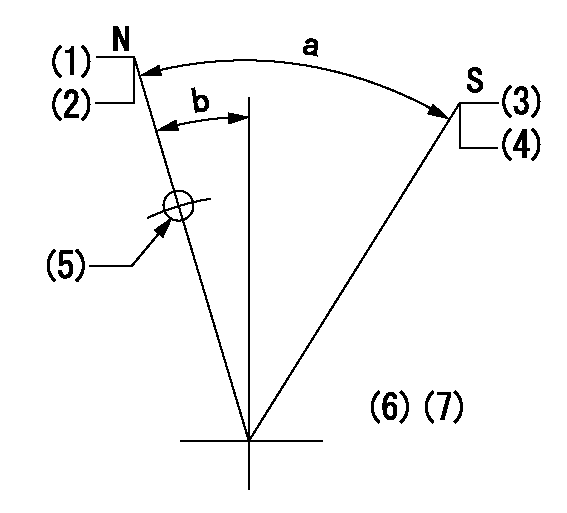

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa

(2)Stopper bolt setting

(3)Rack position = bb or less

(4)Stopper bolt setting

(5)Use the hole above R = cc

(6)No return spring

(7)Set the stopper bolt at the lever angle.

----------

aa=(15.3)mm bb=3.2mm cc=37mm

----------

a=40deg+-5deg b=8deg+-5deg

----------

aa=(15.3)mm bb=3.2mm cc=37mm

----------

a=40deg+-5deg b=8deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=12deg

----------

a=(6deg)

----------

aa=12deg

----------

a=(6deg)

Information:

Image1.1.1

5. Attach a hose to the other end of the fuel rail and hold the free end of the hose in a cup/bucket of water. Hose shown is a JIC 37o ?6 hose. Refer to Illustration 1.2.1

Image1.2.1

6. Pressurize the cooling system with compressed air and regulate pressure between 5-15 psi.

Do Not Exceed 15 psi or Cooling System Damage Can Result.

7. Submerse the hose in a cup/bucket of water.

8. Monitor for 10 minutes and check for a steady rate of air bubbles coming out of the hose that is submersed in the cup/bucket of water.

9. If steady stream of air is present, replace the cylinder head, coolant regulators, and both 030-7937 port connectors. Depending on the application, you will need to replace some cooling system seals. (List of seals by application to be included)

10. Once the cylinder heads have been replaced pressure test the head again using the same procedure. Once this has been completed the cooling system should be flushed using instructions listed below.

Cleaning the Cooling System

1. Drain all of the coolant form cooling system.

2. Fill the cooling system with clean water.

3. Start engine and run it until the thermostat opens.

4. Add two cups of non-foaming liquid automatic dish washer soap.

Note: Do not use plain dish soap. Aeration of the cooling system and resultant damage could occur.

5. After the soap has bee added run engine for approximately twenty minutes. Check to see if the fuel is breaking up.

6. If the fuel is still not breaking up than add two more cups of soap and run for 10 minutes. Drain mixture from cooling system.

7. Fill cooling system with clean water and check surface for fuel. If fuel is present, repeat steps 3 through 7. When water is clear, drain and rinse the cooling system one more time. Then add coolant and conditioner.