Information injection-pump assembly

ZEXEL

106676-2331

1066762331

Rating:

Cross reference number

ZEXEL

106676-2331

1066762331

Zexel num

Bosch num

Firm num

Name

106676-2331

INJECTION-PUMP ASSEMBLY

14CA PE6P,6PD PE

14CA PE6P,6PD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-4620

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.8

4.75

4.85

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

8.4

Pump speed

r/min

1000

1000

1000

Each cylinder's injection qty

mm3/st.

101.5

98.5

104.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

5.5+-0.5

Pump speed

r/min

350

350

350

Each cylinder's injection qty

mm3/st.

12

10.2

13.8

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(8.4)

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

101.5

99.5

103.5

Basic

*

Fixing the lever

*

Boost pressure

kPa

26.7

26.7

Boost pressure

mmHg

200

200

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+0.85

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

116

110

122

Fixing the lever

*

Boost pressure

kPa

26.7

26.7

Boost pressure

mmHg

200

200

Injection quantity adjustment_05

Adjusting point

D

Rack position

R2(R1+1)

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

117.5

109.9

125.1

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_06

Adjusting point

E

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

100

60

140

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

500

500

500

Rack position

R2(R1+1)

Boost pressure

kPa

7.3

6

8.6

Boost pressure

mmHg

55

45

65

Boost compensator adjustment_02

Pump speed

r/min

500

500

500

Rack position

(10)

Boost pressure

kPa

13.3

13.3

13.3

Boost pressure

mmHg

100

100

100

Timer adjustment

Pump speed

r/min

0

Advance angle

deg.

2.5

2

3

Timer adjustment_02

Pump speed

r/min

-

Advance angle

deg.

2.5

2

3

Remarks

Measure speed (beginning of operation).

Measure speed (beginning of operation).

Timer adjustment_03

Pump speed

r/min

-

Advance angle

deg.

0

0

0

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

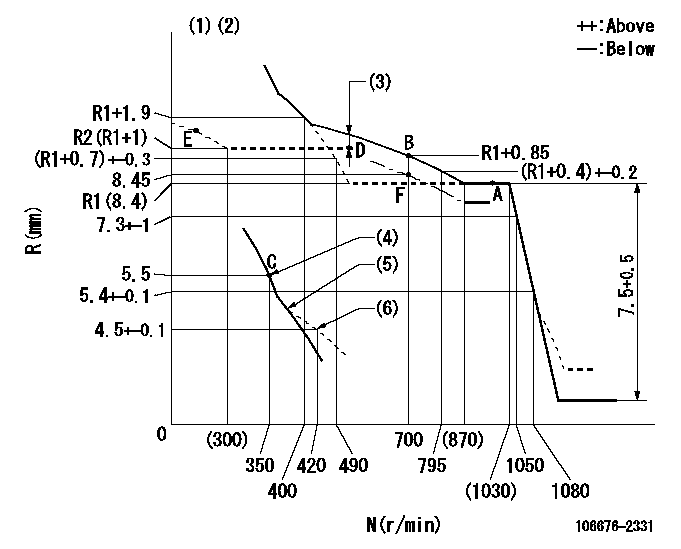

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Boost compensator cancel stroke: BSL

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Boost compensator stroke: BCL

(4)Main spring setting

(5)Damper spring setting

(6)Damper spring setting

----------

BSL=1.6mm BCL=(0.6)mm

----------

----------

BSL=1.6mm BCL=(0.6)mm

----------

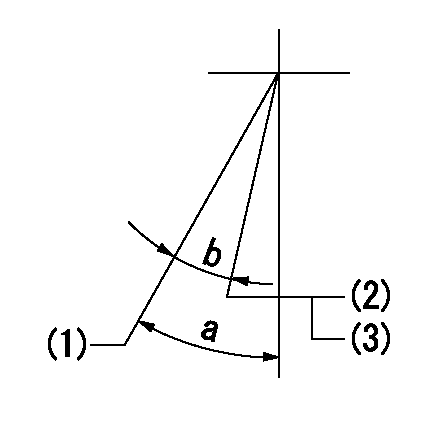

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=15.5deg+-5deg b=15deg+-5deg

----------

----------

a=15.5deg+-5deg b=15deg+-5deg

0000000901

(1)Normal full load

(2)Rack position = aa, speed = bb (half load)

(3)Stopper bolt setting

----------

aa=8.45mm bb=700r/min

----------

a=25deg+-5deg b=3deg+-3deg

----------

aa=8.45mm bb=700r/min

----------

a=25deg+-5deg b=3deg+-3deg

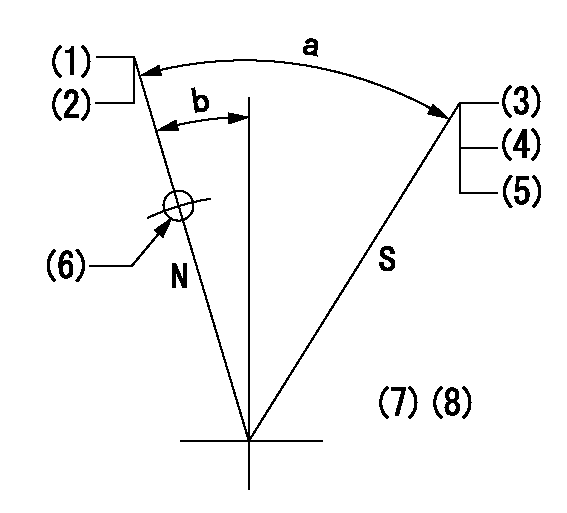

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa

(2)Stopper bolt setting

(3)Rack position = bb or less

(4)Stopper bolt setting

(5)Normal stop

(6)Use the hole above R = cc

(7)Set the stopper bolt at the lever angle.

(8)No return spring

----------

aa=(15.3)mm bb=3.2mm cc=37mm

----------

a=40deg+-5deg b=8deg+-5deg

----------

aa=(15.3)mm bb=3.2mm cc=37mm

----------

a=40deg+-5deg b=8deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=12deg

----------

a=(6deg)

----------

aa=12deg

----------

a=(6deg)

Information:

16Apr2007

B330

D7N6

Z889

Before/After

(Limited distribution)

PRODUCT SUPPORT PROGRAM FOR REPLACING EXISTING DIESEL PARTICULATE FILTERS (DPG'S) ON CERTAIN 285HP APPLICATIONS OF C-9 ENGINES

1091 PS42384

This Program must be administered either before or after failure.In either case the decision whether to apply the Program is made by the dealer. When reporting the repair, use "PS42384" as the Part Numberand "7755" as the Group Number. If administered before failure, use "56" as the Warranty Claim Description Code and "T" as the SIMS Description code.If administered after failure, use "96" as the Warranty Claim Description Code, and "Z" as the SIMS Description Code.

The information supplied in this service letter may not be valid after the termination date of this program.Do not perform the work outlined in this Service Letter after the termination date without first contacting your Caterpillar product analyst.

TERMINATION DATE

30Apr2009

PROBLEM

The existing Diesel Particulate Filter (DPF) filter module (272-2425) can plug with soot too rapidly on certain 285HP applications of C9 MTB engines. If the existing filter plugs, the result is excessive exhaust backpressure or failed filter, which allows soot to pass through.

AFFECTED PRODUCT

Model Identification Number

C9 MTB01562-01574, 1579-1585, 1588-1596, 1598-1602, 1604-1646, 1737-1743, 1754-1766

PARTS NEEDED

No parts needed for this program

ACTION REQUIRED

Replace current DPF filter with CCRT particulate filter technology.

Reference Special Instruction REHS3787. Parts will be supplied as a direct shipment from the factory to the dealer.

If additional information is required for receiving parts please contact Kory Endress at (309)578-3495 or Endress_Kory_L.

SERVICE CLAIM ALLOWANCES

Product smu/age whichever comes first Caterpillar Dealer Suggested Customer Suggested

Parts % Labor Hrs% Parts % Labor Hrs% Parts % Labor Hrs%

0-300000 miles,

0-60 mo 100.0% 100.0% 0.0% 0.0% 0.0% 0.0%

This is a 8.0-hour job

PARTS DISPOSITION

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

Have questions with 106676-2331?

Group cross 106676-2331 ZEXEL

106676-2331

INJECTION-PUMP ASSEMBLY