Information injection-pump assembly

BOSCH

9 400 612 127

9400612127

ZEXEL

106676-2322

1066762322

MITSUBISHI

ME158824

me158824

Rating:

Service parts 106676-2322 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

ME158263

12.

Open Pre:MPa(Kqf/cm2)

17.7{180}/21.6{220}

14.

NOZZLE

Include in #1:

106676-2322

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 612 127

9400612127

ZEXEL

106676-2322

1066762322

MITSUBISHI

ME158824

me158824

Zexel num

Bosch num

Firm num

Name

106676-2322

9 400 612 127

ME158824 MITSUBISHI

INJECTION-PUMP ASSEMBLY

6D24T K 14CA INJECTION PUMP ASSY PE6P,6PD PE

6D24T K 14CA INJECTION PUMP ASSY PE6P,6PD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-4620

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.8

4.75

4.85

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

8.9

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

123

120

126

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Boost pressure

kPa

30.7

30.7

Boost pressure

mmHg

230

230

Injection quantity adjustment_02

Adjusting point

B

Rack position

4.4+-0.5

Pump speed

r/min

425

425

425

Average injection quantity

mm3/st.

9.5

6.9

12.1

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_03

Adjusting point

D

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

145

125

165

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Rack limit

*

Boost compensator adjustment

Pump speed

r/min

700

700

700

Rack position

R1-1.25

Boost pressure

kPa

4

2.7

5.3

Boost pressure

mmHg

30

20

40

Boost compensator adjustment_02

Pump speed

r/min

700

700

700

Rack position

R1(8.9)

Boost pressure

kPa

17.3

10.6

24

Boost pressure

mmHg

130

80

180

Timer adjustment

Pump speed

r/min

0

Advance angle

deg.

2.5

2

3

Timer adjustment_02

Pump speed

r/min

300

Advance angle

deg.

2.5

2

3

Remarks

Start

Start

Timer adjustment_03

Pump speed

r/min

-

Advance angle

deg.

0

0

0

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

Test data Ex:

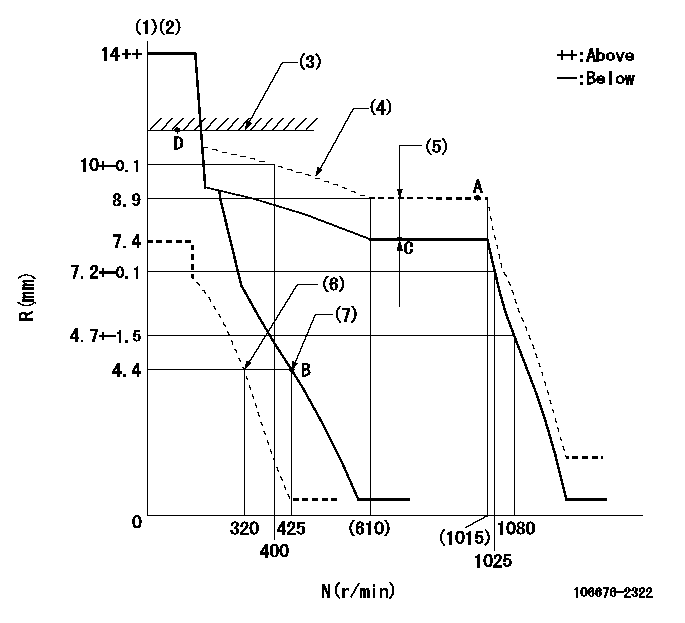

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Notch fixed: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)The torque control spring must does not have a set force.

(5)Boost compensator stroke: BCL

(6)Set idle sub-spring

(7)Main spring setting

----------

K=8 BCL=1.25+-0.1mm

----------

----------

K=8 BCL=1.25+-0.1mm

----------

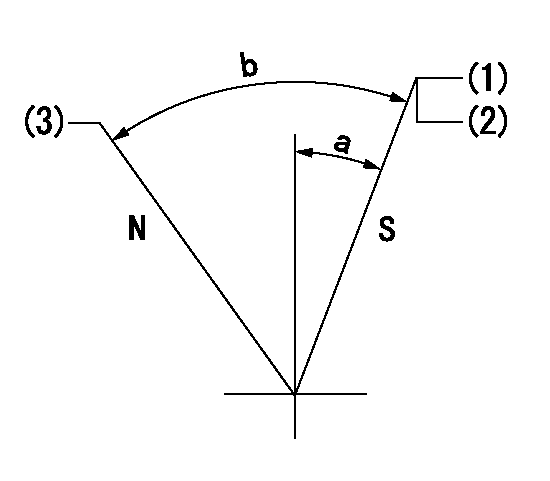

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=(20deg)+-5deg b=(2deg)+-5deg

----------

----------

a=(20deg)+-5deg b=(2deg)+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Pump speed aa and rack position bb (to be sealed at delivery)

(2)Stopper bolt setting

(3)Normal

----------

aa=0r/min bb=1-0.5mm

----------

a=35deg+-5deg b=70deg+-5deg

----------

aa=0r/min bb=1-0.5mm

----------

a=35deg+-5deg b=70deg+-5deg

0000001501 TAMPER PROOF

Tamperproofing-equipped boost compensator cover installation procedure

(A) After adjusting the boost compensator, tighten the bolts to remove the heads.

(1)Before adjusting the governor and the boost compensator, tighten the screw to the specified torque.

(Tightening torque T = T1 maximum)

(2)After adjusting the governor and the boost compensator, tighten to the specified torque to break off the bolt heads.

(Tightening torque T = T2)

----------

T1=2.5N-m(0.25kgf-m) T2=2.9~4.4N-m(0.3~0.45kgf-m)

----------

----------

T1=2.5N-m(0.25kgf-m) T2=2.9~4.4N-m(0.3~0.45kgf-m)

----------

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=12deg

----------

a=(6deg)

----------

aa=12deg

----------

a=(6deg)

Information:

PARTS NEEDED

Qty

Part Number Description

2 1790133 FILM-AIR SHUTOFF

2 2898498 DAMPER AS

ACTION REQUIRED

Refer to the attached Rework Procedure.

OWNER NOTIFICATION

U.S. and Canadian owners will receive the attached Owner Notification.

SERVICE CLAIM ALLOWANCES

Caterpillar Dealer Suggested Customer Suggested

Parts % Labor Hrs% Parts % Labor Hrs% Parts % Labor Hrs%

100% 100% 0% 0% 0% 0%

This is a 1.0-hour job

PARTS DISPOSITION

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

MAKE EVERY EFFORT TO COMPLETE THIS PROGRAM AS SOON AS POSSIBLE.

COPY OF OWNER NOTIFICATION FOR U.S. AND CANADIAN OWNERS

XYZ Corporation

3240 Arrow Drive

Anywhere, YZ 99999

PRIORITY - PRODUCT IMPROVEMENT PROGRAM FOR ADDING VIBRATION DAMPERS TO AIR SHUT OFFS

MODELS INVOLVED - CERTAIN 3500 DIESEL ENGINES

Dear Caterpillar Product Owner:

New vibration dampers need to be installed on the products listed. You will not be charged for the service performed. Contact your local Caterpillar dealer immediately to schedule this service. The dealer will advise you of the time required to complete this service.

It is VERY IMPORTANT that your Air Shut Offs be tested every 500 operating hours and the vibration dampers installed on the ASOs need to be inspected/serviced every 6000 operating hours. Please contact your Caterpillar Dealer for a copy of Caterpillar Special Instruction REHS3005, which details this procedure. A COPY OF THIS DOCUMENT SHOULD BE PLACED IN THE APPLICABLE Operating and Maintenance Manuals.

Please refer the dealer to their Service Letter dated 27Jul2006 when scheduling this service.

We regret the inconvenience this may cause you, but urge you to have this service performed as soon as possible to prevent unscheduled downtime.

Caterpillar Inc.

Identification #(s)

Attached to 27Jul2006 Service Letter

Rework Procedure

1. Remove existing plug from bottom of each Air Shut Off (ASO) housing, Image 1.1.1

Image1.1.1

2. Install new Vibration Damper P/N 289-8498 into the hole as shown in image 1.2.1, insuring that the threads are coated with Thread lock P/N 9S-3263 or 4C-4030 and torque the damper to 16 (+/- 2)Nm.

Image1.2.1

3. Install information labels over existing labels on the electrically actuated ASO solenoids as shown in image 1.3.1 or on hydraulically actuated ASO valve covers as shown in image 1.3.2.

Labels in languages other than English are available under the following Part Numbers:

-Arabic 297-2613

-French 297-2614

-German 297-2615

-Spanish 297-2616

-Portuguese 297-2617

-Russian 297-2618

Image1.3.1

Image1.3.2

Have questions with 106676-2322?

Group cross 106676-2322 ZEXEL

Mitsubishi

Mitsubishi

106676-2322

9 400 612 127

ME158824

INJECTION-PUMP ASSEMBLY

6D24T

6D24T