Information injection-pump assembly

BOSCH

9 400 617 439

9400617439

ZEXEL

106676-2280

1066762280

MITSUBISHI

ME153213

me153213

Rating:

Cross reference number

BOSCH

9 400 617 439

9400617439

ZEXEL

106676-2280

1066762280

MITSUBISHI

ME153213

me153213

Zexel num

Bosch num

Firm num

Name

106676-2280

9 400 617 439

ME153213 MITSUBISHI

INJECTION-PUMP ASSEMBLY

6D22T2 K 14CA INJECTION PUMP ASSY PE6P,6PD PE

6D22T2 K 14CA INJECTION PUMP ASSY PE6P,6PD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-4620

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.8

4.75

4.85

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

9

Pump speed

r/min

700

700

700

Each cylinder's injection qty

mm3/st.

131.5

128.2

134.8

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

F

Rack position

5+-0.5

Pump speed

r/min

500

500

500

Each cylinder's injection qty

mm3/st.

16.5

14

19

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(9)

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

131.5

130.5

132.5

Basic

*

Fixing the lever

*

Boost pressure

kPa

32

32

Boost pressure

mmHg

240

240

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1(9)

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

145

141.8

148.2

Difference in delivery

mm3/st.

6.4

6.4

6.4

Fixing the lever

*

Boost pressure

kPa

32

32

Boost pressure

mmHg

240

240

Injection quantity adjustment_05

Adjusting point

C

Rack position

5.7+-0.5

Pump speed

r/min

225

225

225

Each cylinder's injection qty

mm3/st.

16.5

14

19

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Remarks

Perform adjustment of maximum variation between cylinders and confirm point C.

Perform adjustment of maximum variation between cylinders and confirm point C.

Injection quantity adjustment_06

Adjusting point

E

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

90

70

110

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

600

600

600

Rack position

R2(R1-1.

45)

Boost pressure

kPa

8.7

8.7

8.7

Boost pressure

mmHg

65

65

65

Boost compensator adjustment_02

Pump speed

r/min

600

600

600

Rack position

7.8

Boost pressure

kPa

10

8.7

11.3

Boost pressure

mmHg

75

65

85

Boost compensator adjustment_03

Pump speed

r/min

600

600

600

Rack position

8.4

Boost pressure

kPa

14

7.3

20.7

Boost pressure

mmHg

105

55

155

Boost compensator adjustment_04

Pump speed

r/min

600

600

600

Rack position

R1(9)

Boost pressure

kPa

18.7

18.7

18.7

Boost pressure

mmHg

140

140

140

Timer adjustment

Pump speed

r/min

(N1+50)-

-

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

N1

Advance angle

deg.

0.5

Remarks

Measure the actual speed.

Measure the actual speed.

Timer adjustment_03

Pump speed

r/min

N2

Advance angle

deg.

1.5

1

2

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

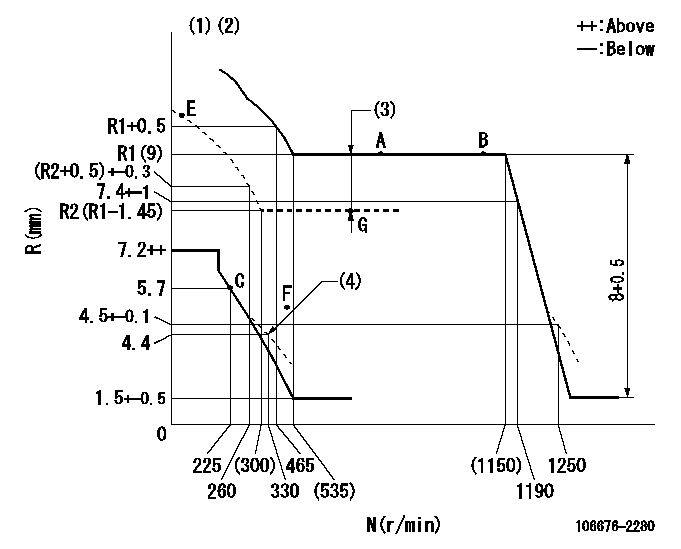

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Tolerance for racks not indicated: +-0.05mm.

(2)Boost compensator cancel stroke: BSL

(3)Boost compensator stroke: BCL

(4)Damper spring setting

----------

BSL=2.2mm BCL=1.45+-0.1mm

----------

----------

BSL=2.2mm BCL=1.45+-0.1mm

----------

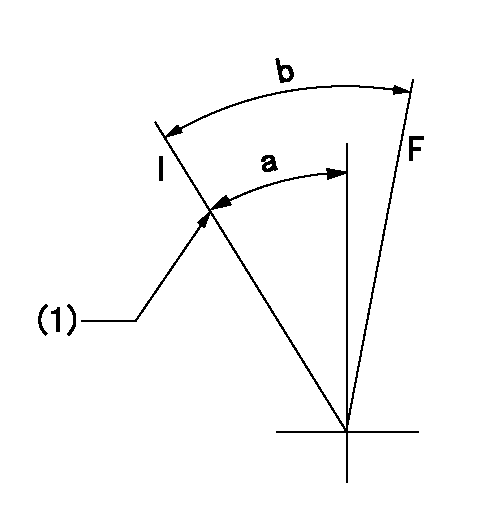

Speed control lever angle

F:Full speed

----------

----------

a=15deg+-5deg

----------

----------

a=15deg+-5deg

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=24deg+-5deg b=28deg+-3deg

----------

----------

a=24deg+-5deg b=28deg+-3deg

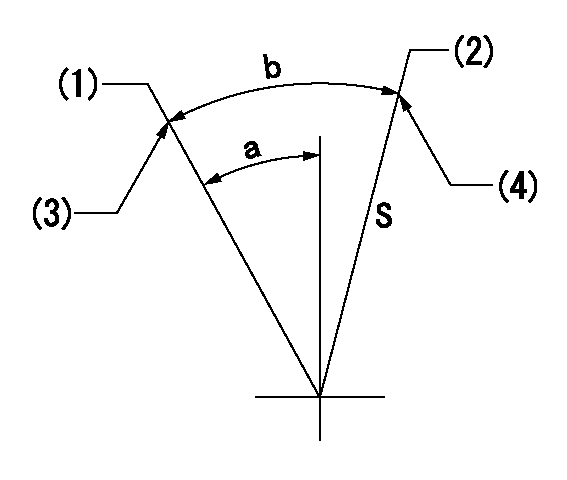

Stop lever angle

S:Stop the pump.

(1)Free (at delivery)

(2)Rack position = aa

(3)Stopper bolt setting

(4)Stopper bolt setting

----------

aa=4.1-0.5mm

----------

a=25.5deg+-5deg b=37deg+7deg-5deg

----------

aa=4.1-0.5mm

----------

a=25.5deg+-5deg b=37deg+7deg-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=9deg

----------

a=(7deg)

----------

aa=9deg

----------

a=(7deg)

Information:

APRIL 2010

INFORMATION RELEASE MEMO

Reman

PELJ1163 ?2010 Caterpillar CAT REMAN ANNOUNCES AN APPEARANCE CHANGE TO MECHANICAL UNIT INJECTORS FOR 3600 ENGINES

Announcement

In the past, Reman 3600 mechanical unit injectors consistently had only one drill hole in the body. Effective immediately, dealers will now see some bodies with one drill hole and some bodies with two drill holes. Validation tests confirm the number of drill holes will not impact quality, reliability, durability, fit, or performance. Affected part numbers are listed in the table below.

* For serial number specific information please see SISWEB.

Effective immediately, Figure 1 and Figure 2 will both represent acceptable 3600 mechanical unit injector appearances.

Features and Benefits

Cat? Reman Fuel Injectors offer excellent value to customers. Customers who want fast repair turn-around, superior quality and reliability, and lower repair costs will benefit from the use of these remanufactured fuel transfer pumps. Cat Reman Fuel Injectors provide immediate, off-the-shelf availability at a fraction of the new price.

Features Benefits

All critical engineering changes and updates included Improved reliability and performance

Worldwide availability through Cat parts distribution system Customer access regardless of location

Backed by Caterpillar parts warranty Consistent support

Core Acceptance

Core Acceptance Criteria for Caterpillar Remanufactured Mechanical Unit Injectors is simple, visual, and requires no special tools. Consult the Unit Injectors ? Mechanical Core Acceptance Criteria SELD0030 for complete details.

Warranty

Please consult the appropriate Cat parts warranty statement for your area.

Core Management

Please refer to the Cat Core Management Information System (CMIS 2) Parts Information application describing all Cat Reman part/CAF and related information. Also refer to other CMIS 2 inquiry applications such as Customer Profiles, Inspection Reason Codes, Inspection Line Inquiry, Add Charge Information, Entitlement Activity, Entitlement Inquiry, CCR Inquiry, CCR Entry, Shipment Processing; Process Packaging Grief; and Reporting to properly manage core returns and monitor inspection performance. This information will be available to all dealers worldwide after your CMIS 2 conversion date. In the meantime, please continue to use the current CMIS Entitlement Parts Inquiry Screen describing the list of parts in a Core Acceptability Family (CAF) and related part number detail.

For the latest updates of Reman Policies and Core Management (SELD0122), Core Management Systems & Operations Procedures (SELD0040), and Shipping Instructions (SELD0039), go to the Reman Dealer website https://catreman.cat.com. If you have any questions regarding core return processing, feel free to call Corinth toll free at (800) 537-2928. Outside the US please refer to the Core section of the Reman website for appropriate contact information for your region.

For assistance with technical questions, call the Peoria Reman Technical Help Line also toll free at (888) 88-REMAN (outside the US call non-toll free +1-309-494-4342), or use our E-mail address--Reman_Help.

Have questions with 106676-2280?

Group cross 106676-2280 ZEXEL

Mitsubishi

Mitsubishi

106676-2280

9 400 617 439

ME153213

INJECTION-PUMP ASSEMBLY

6D22T2

6D22T2