Information injection-pump assembly

ZEXEL

106675-4830

1066754830

Rating:

Cross reference number

ZEXEL

106675-4830

1066754830

Zexel num

Bosch num

Firm num

Name

106675-4830

INJECTION-PUMP ASSEMBLY

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131425-1620

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

RED3 control unit part number

407910-2

470

RED3 rack sensor specifications

mm

15

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.5

4.45

4.55

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Rack position

(10.1)

Vist

V

1.98

1.98

1.98

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

125.5

124

127

Max. variation between cylinders

%

0

-3

3

Basic

*

Injection quantity adjustment_02

Rack position

(6.6)

Vist

V

2.7

2.6

2.8

Pump speed

r/min

410

410

410

Average injection quantity

mm3/st.

12.5

11.3

13.7

Max. variation between cylinders

%

0

-15

15

Injection quantity adjustment_03

Remarks

Rack limit setting V = 0.9-0.04

Rack limit setting V = 0.9-0.04

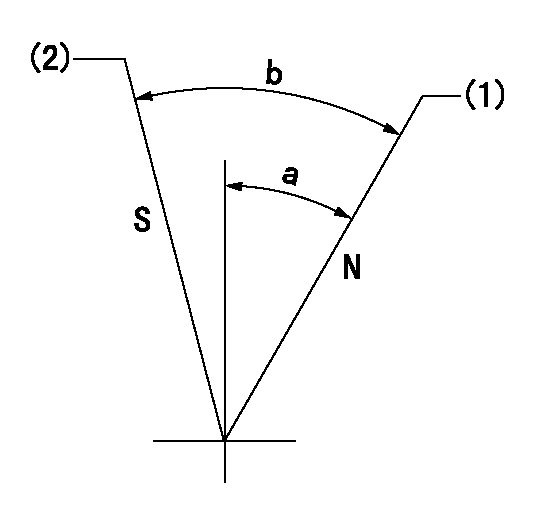

Test data Ex:

Speed control lever angle

N:Pump normal

S:Stop the pump.

(1)Vist = aa, (rack position = bb)

(2)Rack position = cc

----------

aa=0.8V bb=16mm cc=1mm

----------

a=19deg+-5deg b=29deg+-5deg

----------

aa=0.8V bb=16mm cc=1mm

----------

a=19deg+-5deg b=29deg+-5deg

0000000901

(1)Pump vertical direction

(2)Position of camshaft's key groove at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(60deg)

----------

----------

a=(60deg)

Stop lever angle

(Rs) rack sensor specifications

(C/U) control unit part number

(V) Rack sensor output voltage

(R) Rack position (mm)

1. Confirming governor output characteristics (rack 15 mm, span 6 mm)

(1)When the output voltages of the rack sensor are V1 and V2, check that the rack positions R1 and R2 in the table above are satisfied.

----------

----------

----------

----------

Information:

The electrical system is a combination of two separate electric circuits: The charging circuit and the starting circuit. Each circuit is dependent on some of the same components. The battery (batteries), on-off start switch, circuit breaker, ammeter, cables and wires from the battery are common in each of the circuits.

The ignition switch must be ON to allow the electrical system to function. Some charging circuit components will be damaged if the engine is operated with the ignition switch OFF.

The charging circuit is in operation when the diesel engine is operating. The electricity producing (charging) unit is an alternator. A regulator in the circuit senses the state of charge in the battery and regulates the alternator output to keep the batter fully charged.The alternator has four main components: end frame assembly (brush end), rotor assembly, stator and shell assembly, and end frame assembly (drive end).A separate regulator senses the charge condition of the battery as well as electrical system power demand and controls the alternator output accordingly by limiting the field current.

ALTERNATOR

Never operate the alternator without the battery in the circuit. Making or breaking an alternator connection with a heavy load on the circuit will sometimes result in regulator damage.

The starting motor is a device used to rotate the flywheel of an engine fast enough to start the engine.

ALTERNATOR REGULATOR

ELECTRIC STARTING MOTORThe starting motor includes a solenoid. The solenoid engages the pinion with the ring gear on the engine flywheel, when the solenoid is energized. The pinion always engages before the electric contacts in the solenoid causes the circuit between the battery and the starting motor to close. An overrunning clutch protects the starting motor from being overspeeded. Releasing the start-switch disengages the pinion and flywheel ring gear.A solenoid is a magnetic switch that uses low current to close a high current circuit. The solenoid is an electro-magnet with a movable core. There are contacts on the end of the core. The contacts are held apart by a spring pushing the core away from the magnetic center of the coil. Low current energizes the coil and forms a magnetic field. The magnetic field pulls the core to the center of the coil, closing the contacts and completing the starting circuit.

SOLENOID

The ignition switch must be ON to allow the electrical system to function. Some charging circuit components will be damaged if the engine is operated with the ignition switch OFF.

The charging circuit is in operation when the diesel engine is operating. The electricity producing (charging) unit is an alternator. A regulator in the circuit senses the state of charge in the battery and regulates the alternator output to keep the batter fully charged.The alternator has four main components: end frame assembly (brush end), rotor assembly, stator and shell assembly, and end frame assembly (drive end).A separate regulator senses the charge condition of the battery as well as electrical system power demand and controls the alternator output accordingly by limiting the field current.

ALTERNATOR

Never operate the alternator without the battery in the circuit. Making or breaking an alternator connection with a heavy load on the circuit will sometimes result in regulator damage.

The starting motor is a device used to rotate the flywheel of an engine fast enough to start the engine.

ALTERNATOR REGULATOR

ELECTRIC STARTING MOTORThe starting motor includes a solenoid. The solenoid engages the pinion with the ring gear on the engine flywheel, when the solenoid is energized. The pinion always engages before the electric contacts in the solenoid causes the circuit between the battery and the starting motor to close. An overrunning clutch protects the starting motor from being overspeeded. Releasing the start-switch disengages the pinion and flywheel ring gear.A solenoid is a magnetic switch that uses low current to close a high current circuit. The solenoid is an electro-magnet with a movable core. There are contacts on the end of the core. The contacts are held apart by a spring pushing the core away from the magnetic center of the coil. Low current energizes the coil and forms a magnetic field. The magnetic field pulls the core to the center of the coil, closing the contacts and completing the starting circuit.

SOLENOID

Have questions with 106675-4830?

Group cross 106675-4830 ZEXEL

Komatsu

Komatsu

106675-4830

INJECTION-PUMP ASSEMBLY