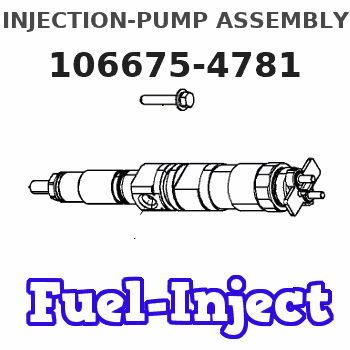

Information injection-pump assembly

BOSCH

9 400 617 417

9400617417

ZEXEL

106675-4781

1066754781

NIIGATA-TEKKOU

75G47230B

75g47230b

Rating:

Service parts 106675-4781 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

7.

COUPLING PLATE

8.

_

9.

_

10.

NOZZLE AND HOLDER ASSY

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

29.4(300)

15.

NOZZLE SET

Include in #1:

106675-4781

as INJECTION-PUMP ASSEMBLY

Cross reference number

Zexel num

Bosch num

Firm num

Name

Information:

A pressurized cooling system serves two purposes. First, it permits safe operation at coolant temperatures higher than the normal boiling point; thereby, providing a margin of cooling for those intermittent peak loads. Secondly, it prevents cavitation in the water pump and reduces the possibility of air or steam pockets forming in the coolant passages.Many times engine overheating is caused by failure to make simple systematic inspections. Visual inspections should be made before testing. Coolant Level: Check the engine coolant level with engine stopped and cool. Always release cooling system pressure before checking. Fill to the proper level with water, as free as possible from scale forming minerals, not softened water. During freezing weather add sufficient permanent type antifreeze to the coolant to prevent freezing. Make up water added without the proper proportions of inhibitor can cause excessive mineral deposits. (Use inhibitor as recommended on container.)Most commercial antifreeze solutions contain rust inhibitors, however, it is recommended the adding of Caterpillar Coolant System Inhibitor to glycol base antifreeze if protection is for temperatures above -20°F (-29°C). If protection is for temperatures -20°F (-29°C) or below, do not add inhibitor.

Inhibitor contains alkali. Avoid contact with eyes. Avoid prolonged or repeated contact with skin.

Add coolant slowly to a hot engine (engine running) to prevent possible cracking or distorting the cylinder heads.

If a loss of coolant is noticeable, check for leaks in the system. After filling the system, start the engine and add coolant as necessary to maintain a full system during engine warm up. Running the engine at operating temperature will permit the temperature regulator to open and allow the coolant to circulate and purge air from the entire system. Some systems will normally loose some coolant during initial warm up cycle. Cleaning the Radiator (External): Clean dirt and trash from between the tubes of the radiator. Accumulation of debris may cause excessively high operating temperature. Wash, brush or blow the dirt out with whichever method is available and most effective. When cleaning with air do not exceed 30 PSI (2 kg/cm2). Cleaning the Cooling System (Internal): Clean the cooling system periodically. Mineral deposits can cause serious engine damage by retarding the transfer of heat to the coolant. A deposit of lime 1/32 inch thick insulates the same amount as 2 inches of steel, reducing the heat transfer substantially. Loose scale and sediment deposited in the cooling system will reduce circulation, resulting in possible engine damage. To clean, stop the engine when it is at normal operating temperature and drain as quickly as possible. Flush thoroughly, then fill with a solution of 3.2 ounces of Oxalic Acid or Sodium Bisulfate per one gallon of water. Run the engine at operating temperature one-half to one hour, then drain and flush until water is clear. Fill with a solution of .8 of an ounce of Sal Soda per one gallon of water and run the engine ten minutes. Drain, flush and fill with water, adding corrosion inhibitor or the desired amount of antifreeze.

ENGINE DRAIN

Inhibitor contains alkali. Avoid contact with eyes. Avoid prolonged or repeated contact with skin.

Add coolant slowly to a hot engine (engine running) to prevent possible cracking or distorting the cylinder heads.

If a loss of coolant is noticeable, check for leaks in the system. After filling the system, start the engine and add coolant as necessary to maintain a full system during engine warm up. Running the engine at operating temperature will permit the temperature regulator to open and allow the coolant to circulate and purge air from the entire system. Some systems will normally loose some coolant during initial warm up cycle. Cleaning the Radiator (External): Clean dirt and trash from between the tubes of the radiator. Accumulation of debris may cause excessively high operating temperature. Wash, brush or blow the dirt out with whichever method is available and most effective. When cleaning with air do not exceed 30 PSI (2 kg/cm2). Cleaning the Cooling System (Internal): Clean the cooling system periodically. Mineral deposits can cause serious engine damage by retarding the transfer of heat to the coolant. A deposit of lime 1/32 inch thick insulates the same amount as 2 inches of steel, reducing the heat transfer substantially. Loose scale and sediment deposited in the cooling system will reduce circulation, resulting in possible engine damage. To clean, stop the engine when it is at normal operating temperature and drain as quickly as possible. Flush thoroughly, then fill with a solution of 3.2 ounces of Oxalic Acid or Sodium Bisulfate per one gallon of water. Run the engine at operating temperature one-half to one hour, then drain and flush until water is clear. Fill with a solution of .8 of an ounce of Sal Soda per one gallon of water and run the engine ten minutes. Drain, flush and fill with water, adding corrosion inhibitor or the desired amount of antifreeze.

ENGINE DRAIN