Information injection-pump assembly

BOSCH

9 400 617 406

9400617406

ZEXEL

106675-4591

1066754591

Rating:

Cross reference number

BOSCH

9 400 617 406

9400617406

ZEXEL

106675-4591

1066754591

Zexel num

Bosch num

Firm num

Name

106675-4591

9 400 617 406

DAEWOO

INJECTION-PUMP ASSEMBLY

DE12TI K 14CA INJECTION PUMP ASSY PE6P,6PD PE

DE12TI K 14CA INJECTION PUMP ASSY PE6P,6PD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-4420

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.2

4.15

4.25

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

9.9

Pump speed

r/min

1050

1050

1050

Average injection quantity

mm3/st.

116.5

114.5

118.5

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

7+-0.5

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

19.5

18

21

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Test data Ex:

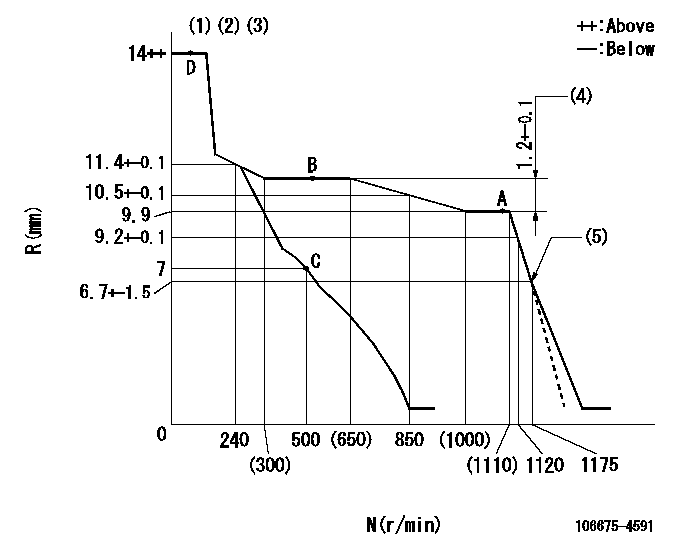

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Notch fixed: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Do not adjust boost compensator spring.

(4)Rack difference between N = N1 and N = N2

(5)Idle sub spring setting: L1.

----------

K=17 N1=1050r/min N2=500r/min L1=6.7+-0.2mm

----------

----------

K=17 N1=1050r/min N2=500r/min L1=6.7+-0.2mm

----------

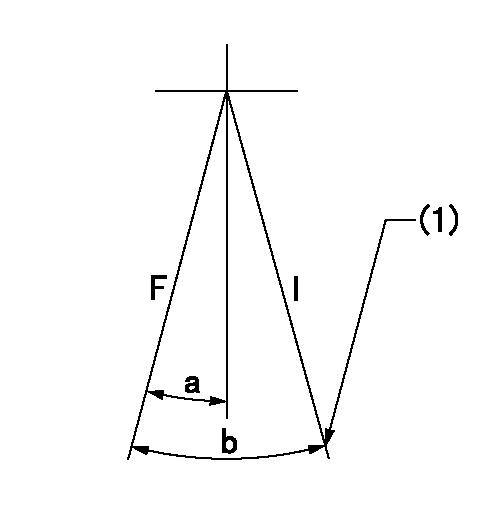

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=(16deg)+-5deg b=(25deg)+-5deg

----------

----------

a=(16deg)+-5deg b=(25deg)+-5deg

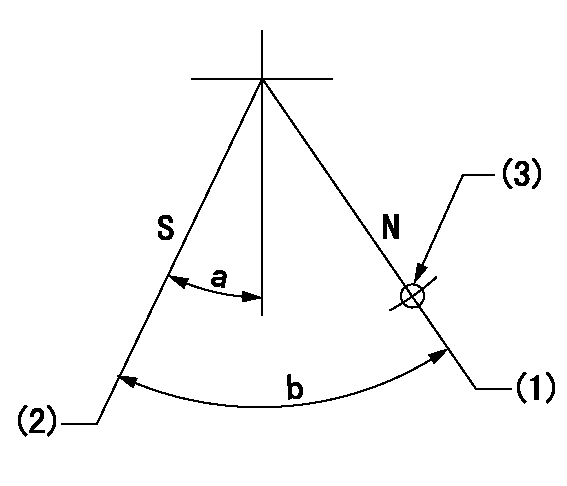

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Normal

(2)Pump speed aa and rack position bb (to be sealed at delivery)

(3)Use the hole above R = cc

----------

aa=0r/min bb=1-0.5mm cc=30mm

----------

a=32deg+-5deg b=70deg+-5deg

----------

aa=0r/min bb=1-0.5mm cc=30mm

----------

a=32deg+-5deg b=70deg+-5deg

0000001501 TAMPER PROOF

Tamperproofing-equipped boost compensator cover installation procedure

(A) After adjusting the boost compensator, tighten the bolts to remove the heads.

(1)Before adjusting the governor and the boost compensator, tighten the screw to the specified torque.

(Tightening torque T = T1 maximum)

(2)After adjusting the governor and the boost compensator, tighten to the specified torque to break off the bolt heads.

(Tightening torque T = T2 maximum)

----------

T1=2.5N-m(0.25kgf-m) T2=2.9~4.4N-m(0.3~0.45kgf-m)

----------

----------

T1=2.5N-m(0.25kgf-m) T2=2.9~4.4N-m(0.3~0.45kgf-m)

----------

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(70deg)

----------

----------

a=(70deg)

Information:

Cat does not warrant the quality or performance of non-Cat fluids.

Do NOT mix brands or types of SCA. Do NOT mix SCAs and extenders.Failure to follow the recommendations can result in shortened cooling system component life.

Use Only Approved SCAs. Conventional coolants require the maintenance addition of SCA throughout their expected life. Do NOT use an SCA with a coolant unless specifically approved by the coolant supplier for use with their coolant. It is the responsibility of the coolant manufacturer to ensure compatibility and acceptable performance.Failure to follow the recommendations can result in shortened cooling system component life.

Follow the maintenance information provided in the “Coolant and General Maintenance Recommendations” section in this Special Publication.Select a commercial diesel engine antifreeze coolant that meets all the requirements given in Table 1. The table contains the requirements for coolant to meet the published service intervals.The provided requirements are applicable to finished coolants and not for the concentrates. When concentrated coolant/antifreeze is mixed, Cat recommends mixing the concentrate with distilled water or with deionized water. If distilled water or deionized water is not available, water which has the required properties may be used. For the water properties, refer to this Special Publication, "General Coolant Information" article.Coolant/antifreezes for heavy-duty applications that meet "ASTM D6210" do not require treatment with SCA at the initial fill. Use the recommended 1:1 or higher concentration with recommended water. Treatment with SCA is required on a maintenance basis.The SCA manufacturer is responsible for ensuring the SCA is compatible with water meeting the “Caterpillar Minimum Acceptable Water Quality Requirements” as found in this Special Publication, and "ASTM D6210-08, Table X1.1". The coolant manufacturer and the SCA manufacturer are responsible to ensure that the products will not cause cooling system harm.Do not mix brands or types of coolants with different brands or types of SCA or extender.If using non Cat coolants, refer to the coolant manufacturer for information on a compatible SCA.Treat the compatible commercial coolant with 3 to 6 percent Cat SCA by volume. Maintain a 3 to 6 percent concentration level of SCA in the cooling system. For more information, refer to this Special Publication, "Conventional Coolant/Antifreeze Cooling System Maintenance" article.

Table 1

Technical Requirements for Commercial Diesel Engine Antifreeze Coolants

Specifications ASTM D6210-08

Additional Requirements Silicon: 100 ppm minimum to 275 ppm maximum

Nitrites: maintained at 1200ppm (70 grains/US gal) minimum to 2400 ppm (140 grains/US gal) maximum

Cat SCA at 3 to 6 percent (if Cat SCA is added)

Maintenance ASTM D6210-08 Add compatible SCA at maintenance intervals

Clean and flush the cooling system at drain intervals

Have questions with 106675-4591?

Group cross 106675-4591 ZEXEL

Komatsu

Komatsu

Dpico

Komatsu

Komatsu

Komatsu

Komatsu

Komatsu

Daewoo

106675-4591

9 400 617 406

INJECTION-PUMP ASSEMBLY

DE12TI

DE12TI