Information injection-pump assembly

BOSCH

9 400 617 397

9400617397

ZEXEL

106675-4452

1066754452

Rating:

Service parts 106675-4452 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

7.

COUPLING PLATE

8.

_

9.

_

10.

NOZZLE AND HOLDER ASSY

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

13.

NOZZLE-HOLDER

14.

NOZZLE

15.

NOZZLE SET

Include in #1:

106675-4452

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 617 397

9400617397

ZEXEL

106675-4452

1066754452

Zexel num

Bosch num

Firm num

Name

106675-4452

9 400 617 397

DAEWOO

INJECTION-PUMP ASSEMBLY

D2366T K

D2366T K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-4420

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.3

4.25

4.35

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

10.8

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

145

143

147

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Boost pressure

kPa

80

80

Boost pressure

mmHg

600

600

Injection quantity adjustment_02

Adjusting point

B

Rack position

4.9+-0.5

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

15.5

14

17

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_03

Adjusting point

E

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

146

146

156

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Rack limit

*

Boost compensator adjustment

Pump speed

r/min

500

500

500

Rack position

R1-1.6

Boost pressure

kPa

13.3

11.3

15.3

Boost pressure

mmHg

100

85

115

Boost compensator adjustment_02

Pump speed

r/min

500

500

500

Rack position

R1-1

Boost pressure

kPa

32

28

36

Boost pressure

mmHg

240

210

270

Boost compensator adjustment_03

Pump speed

r/min

500

500

500

Rack position

R1(10.8)

Boost pressure

kPa

66.7

66.7

66.7

Boost pressure

mmHg

500

500

500

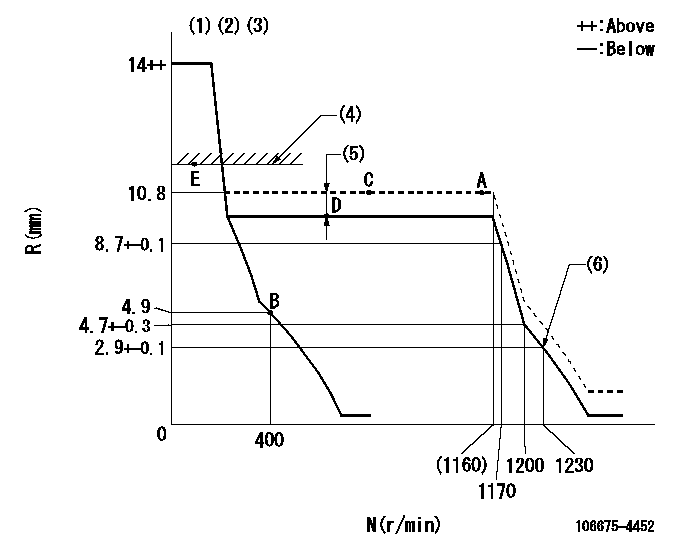

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Deliver without the torque control spring operating.

(4)RACK LIMIT

(5)Boost compensator stroke: BCL

(6)Set idle sub-spring

----------

K=7 BCL=1.6+-0.1mm

----------

----------

K=7 BCL=1.6+-0.1mm

----------

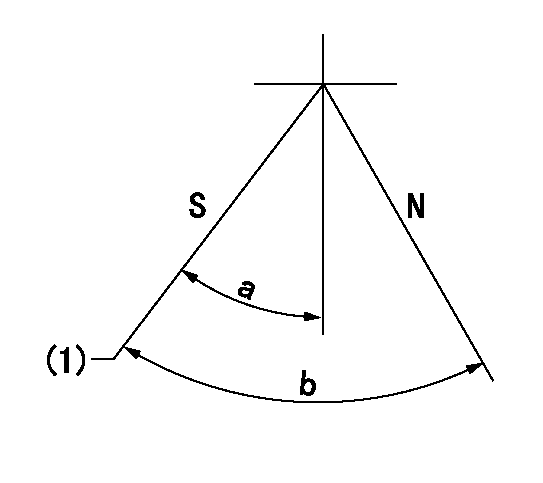

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=10deg+-5deg b=27deg+-5deg

----------

----------

a=10deg+-5deg b=27deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Pump speed aa and rack position bb (to be sealed at delivery)

----------

aa=0r/min bb=1-0.5mm

----------

a=32deg+-5deg b=70deg+-5deg

----------

aa=0r/min bb=1-0.5mm

----------

a=32deg+-5deg b=70deg+-5deg

0000001501 TAMPER PROOF

Tamperproofing-equipped boost compensator cover installation procedure

(A) After adjusting the boost compensator, tighten the bolts to remove the heads.

(1)Before adjusting the governor and the boost compensator, tighten the screw to the specified torque.

(Tightening torque T = T1 maximum)

(2)After adjusting the governor and the boost compensator, tighten to the specified torque to break off the bolt heads.

(Tightening torque T = T2)

----------

T1=2.5N-m(0.25kgf-m) T2=2.9~4.4N-m(0.3~0.45kgf-m)

----------

----------

T1=2.5N-m(0.25kgf-m) T2=2.9~4.4N-m(0.3~0.45kgf-m)

----------

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(70deg)

----------

----------

a=(70deg)

Information:

Introduction

The problem that is identified below does not have a known permanent solution. Until a permanent solution is known, use the solution that is identified below.Problem

Caterpillar has discovered that when certain products equipped with the Caterpillar Regeneration System (CRS) are left idling for extended periods of time (greater than 1 hr) and ambient temps are lower than −15° C (5° F), certain conditions may be met which will disable the ability to regenerate the DPF. If the regeneration system cannot activate, the DPF will accumulate too much soot and must eventually be replaced.The issues Caterpillar has identified in extreme cold ambient conditions are the coolant temperature may become too cold for the regeneration system to activate. Also, the pressure lines which connect the DPF inlet section to the DPF intake pressure sensor may collect condensation and freeze. This freezing causes an E1154 (2) or 3609-18 Low DPF #1 Intake Pressure event code. The event code will disable the regeneration until the fault condition goes away.If you suspect low coolant temperature may be contributing to an inability to regenerate the DPF, review the product status report. The product status report is used for investigating the following fault code trend. If coolant temp is the only issue, you will likely see a combination of the following fault codes:

E995 (2) High DPF #1 Soot Loading or 3719-16 Particulate Trap #1 Soot Load Percent : High - moderate severity (2)

Indicates DPF soot load percent has reached 100 percent

E995(3) High DPF #1 soot loading or 3719-0 Particulate Trap #1 Soot Load Percent : High - most severe (3)

Indicates DPF soot load percent has reached 116 percent

E992(3) DPF Active Regeneration Inhibited Due to Temporary System Lockout or 3714-31 Particulate Trap Active Regeneration Inhibited Due to Temporary System Lockout

Indicates DPF soot load reached 116 percent and 10 minutes has passed since that point. Ability to perform automatic or manual regenerations is disabled. Caterpillar Electronic Technician (ET) regeneration is only type of regeneration allowed.

E991 (3) DPF Active Regeneration Inhibited Due to Permanent System Lockout or 3715-31 Particulate Trap Active Regeneration Inhibited Due to Permanent System Lockout

Indicates DPF soot load percent has reached 140 percent. All types of regeneration are disabled. DPF must be replaced as the amount of soot load will damage the DPF if ignited by regeneration process.If you suspect the pressure line for the DPF intake pressure has frozen, you will see a combination of fault codes. These codes will consist of the codes listed above with the addition of the following codes: E1154 (2) DPF #1 intake pressure low and 3609-18 DPF #1 Intake Pressure : Low - moderate severity (2).Solution

Caterpillar recommends the following when extended idling is likely to occur and ambient temperatures are less than −15° C (5° F):

Turn off machine before the end of shift. Before shutting down, perform a manual DPF regeneration and reduce soot load to 0 percent. The soot load must be above the 15 percent threshold needed to activate a manual DPF regeneration.If extended idling is

The problem that is identified below does not have a known permanent solution. Until a permanent solution is known, use the solution that is identified below.Problem

Caterpillar has discovered that when certain products equipped with the Caterpillar Regeneration System (CRS) are left idling for extended periods of time (greater than 1 hr) and ambient temps are lower than −15° C (5° F), certain conditions may be met which will disable the ability to regenerate the DPF. If the regeneration system cannot activate, the DPF will accumulate too much soot and must eventually be replaced.The issues Caterpillar has identified in extreme cold ambient conditions are the coolant temperature may become too cold for the regeneration system to activate. Also, the pressure lines which connect the DPF inlet section to the DPF intake pressure sensor may collect condensation and freeze. This freezing causes an E1154 (2) or 3609-18 Low DPF #1 Intake Pressure event code. The event code will disable the regeneration until the fault condition goes away.If you suspect low coolant temperature may be contributing to an inability to regenerate the DPF, review the product status report. The product status report is used for investigating the following fault code trend. If coolant temp is the only issue, you will likely see a combination of the following fault codes:

E995 (2) High DPF #1 Soot Loading or 3719-16 Particulate Trap #1 Soot Load Percent : High - moderate severity (2)

Indicates DPF soot load percent has reached 100 percent

E995(3) High DPF #1 soot loading or 3719-0 Particulate Trap #1 Soot Load Percent : High - most severe (3)

Indicates DPF soot load percent has reached 116 percent

E992(3) DPF Active Regeneration Inhibited Due to Temporary System Lockout or 3714-31 Particulate Trap Active Regeneration Inhibited Due to Temporary System Lockout

Indicates DPF soot load reached 116 percent and 10 minutes has passed since that point. Ability to perform automatic or manual regenerations is disabled. Caterpillar Electronic Technician (ET) regeneration is only type of regeneration allowed.

E991 (3) DPF Active Regeneration Inhibited Due to Permanent System Lockout or 3715-31 Particulate Trap Active Regeneration Inhibited Due to Permanent System Lockout

Indicates DPF soot load percent has reached 140 percent. All types of regeneration are disabled. DPF must be replaced as the amount of soot load will damage the DPF if ignited by regeneration process.If you suspect the pressure line for the DPF intake pressure has frozen, you will see a combination of fault codes. These codes will consist of the codes listed above with the addition of the following codes: E1154 (2) DPF #1 intake pressure low and 3609-18 DPF #1 Intake Pressure : Low - moderate severity (2).Solution

Caterpillar recommends the following when extended idling is likely to occur and ambient temperatures are less than −15° C (5° F):

Turn off machine before the end of shift. Before shutting down, perform a manual DPF regeneration and reduce soot load to 0 percent. The soot load must be above the 15 percent threshold needed to activate a manual DPF regeneration.If extended idling is

Have questions with 106675-4452?

Group cross 106675-4452 ZEXEL

Komatsu

Komatsu

Komatsu

Komatsu

Daewoo

106675-4452

9 400 617 397

INJECTION-PUMP ASSEMBLY

D2366T

D2366T