Information injection-pump assembly

ZEXEL

106675-4450

1066754450

Rating:

Cross reference number

ZEXEL

106675-4450

1066754450

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-4420

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.3

4.25

4.35

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

10.8

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

150.6

148.6

152.6

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Boost pressure

kPa

80

80

Boost pressure

mmHg

600

600

Injection quantity adjustment_02

Adjusting point

B

Rack position

4.9+-0.5

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

15.5

14

17

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_03

Adjusting point

E

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

146

146

156

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Rack limit

*

Boost compensator adjustment

Pump speed

r/min

500

500

500

Rack position

R1-0.65

Boost pressure

kPa

13.3

11.3

15.3

Boost pressure

mmHg

100

85

115

Boost compensator adjustment_02

Pump speed

r/min

500

500

500

Rack position

R1(10.8)

Boost pressure

kPa

66.7

66.7

66.7

Boost pressure

mmHg

500

500

500

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Deliver without the torque control spring operating.

(4)RACK LIMIT

(5)Boost compensator stroke: BCL

(6)Set idle sub-spring

----------

K=10 BCL=0.65+-0.1mm

----------

----------

K=10 BCL=0.65+-0.1mm

----------

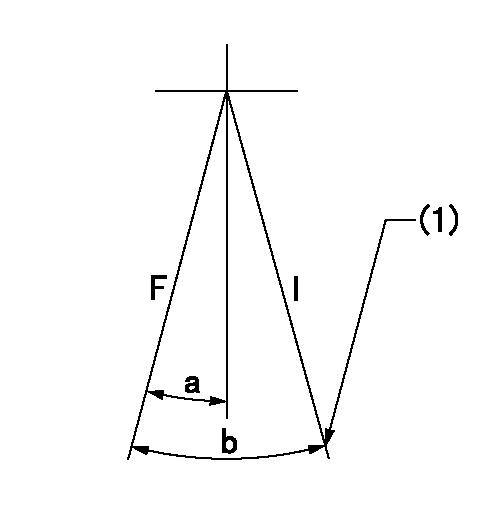

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=10deg+-5deg b=26deg+-5deg

----------

----------

a=10deg+-5deg b=26deg+-5deg

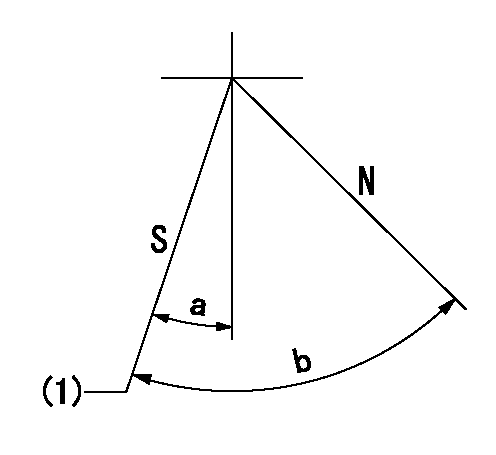

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Pump speed aa and rack position bb (to be sealed at delivery)

----------

aa=0r/min bb=1-0.5mm

----------

a=25deg+-5deg b=70deg+-5deg

----------

aa=0r/min bb=1-0.5mm

----------

a=25deg+-5deg b=70deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(70deg)

----------

----------

a=(70deg)

Information:

The DATA SET screen ID (2) for the correct group will be listed to the right of Line 011 FUEL INJECT PUMP BENCH TEST SPEC NUM (3). Write this number DMXXXX-XX down and proceed to Section ""Displaying the DATA SET Screen When the DATA SET ID Number is Not Known"".Certain pump and governor groups will have multiple DATA SETS. Change in pump design will be tracked by pump serial number. Figure 22 is an example of a serial l number break in the data (1). The original DATA SET DMXXXX number is kept (2) but the new DATA SET has a different change level (3).

Illustration 22 g02797952

Note: Soon you will be able to use the tab key to place the cursor in front of this line. Type an X to select, Figure 21 (4). Press the enter key. The data will be displayed automatically. For now though the data will have to be displayed manually. Figure 23 (1)

Illustration 23 g02797956

Press the pf3 key to return to the ACF2 screen (2) .Proceed to Section ""Displaying the DATA SET Screen When the DATA SET ID Number is Not Known"".Displaying the DATA SET Screen When the DATA SET ID Number is Not Known

At the ACF2/IMS ONLINE MENU SYSTEM screen (1) (TMI 1.04) press the enter key (2). Figure 24

Illustration 24 g02797958

This will display the ACF2/IMS APPLICATION SELECTION MENU. Figure 25 (1) (TMI 1.05)

Illustration 25 g02797959

Use the tab key to place the cursor in front of the line GKN402 TMI - ENGINE AND COMP PERF, type an X to select (2) or type GKN402 at the APPLICATION SELECTION NO. _. (3) Press the enter key. This will display the ACF2/IMS PROGRAM SELECTION MENU screen. Figure 26 (1)

Illustration 26 g02797960

Use the tab key to place the cursor in front of line 03 and type an X to select (2) or type 03 at the PROGRAM SELECTION NO _ (3). Press the enter key. This will display the PERFORMANCE PARAMETERS INQUIRY screen. Figure 27 (1) (TMI 3.03 p1)

Illustration 27 g02797962

Type the appropriate numbers in the DATA REFERENCE NUMBER and CHANGE LEVEL fields (2). Press the enter key. The data set will be displayed on the next screen. Figure 28 (TMI 3.03)

Illustration 28 g02797963

Press the pf3 key to return to the ACF2 screen (1) .Interpreting the Specification Data Set Screens

The following screen contains flow specifications and physical parameters necessary to evaluate a fuel injection pump. Additional parameters such as calibration fluid temperatures and pressures are listed in the manual for the test bench. See Special Instruction, SEHS8200. These screens still apply to this data. Every data set (DMXXXX screen) contains data for many injection pump and governor group part numbers. The data is sorted by the profile or geometry of the basic cam and the lowest level part number of the plunger and barrel group. Most part numbers with the same basic cam, plunger, and barrel groups use the same data.Pages of data in the DATA SETS are arranged in descending pump rpm. Five or six rpm choices are listed. When the

Illustration 22 g02797952

Note: Soon you will be able to use the tab key to place the cursor in front of this line. Type an X to select, Figure 21 (4). Press the enter key. The data will be displayed automatically. For now though the data will have to be displayed manually. Figure 23 (1)

Illustration 23 g02797956

Press the pf3 key to return to the ACF2 screen (2) .Proceed to Section ""Displaying the DATA SET Screen When the DATA SET ID Number is Not Known"".Displaying the DATA SET Screen When the DATA SET ID Number is Not Known

At the ACF2/IMS ONLINE MENU SYSTEM screen (1) (TMI 1.04) press the enter key (2). Figure 24

Illustration 24 g02797958

This will display the ACF2/IMS APPLICATION SELECTION MENU. Figure 25 (1) (TMI 1.05)

Illustration 25 g02797959

Use the tab key to place the cursor in front of the line GKN402 TMI - ENGINE AND COMP PERF, type an X to select (2) or type GKN402 at the APPLICATION SELECTION NO. _. (3) Press the enter key. This will display the ACF2/IMS PROGRAM SELECTION MENU screen. Figure 26 (1)

Illustration 26 g02797960

Use the tab key to place the cursor in front of line 03 and type an X to select (2) or type 03 at the PROGRAM SELECTION NO _ (3). Press the enter key. This will display the PERFORMANCE PARAMETERS INQUIRY screen. Figure 27 (1) (TMI 3.03 p1)

Illustration 27 g02797962

Type the appropriate numbers in the DATA REFERENCE NUMBER and CHANGE LEVEL fields (2). Press the enter key. The data set will be displayed on the next screen. Figure 28 (TMI 3.03)

Illustration 28 g02797963

Press the pf3 key to return to the ACF2 screen (1) .Interpreting the Specification Data Set Screens

The following screen contains flow specifications and physical parameters necessary to evaluate a fuel injection pump. Additional parameters such as calibration fluid temperatures and pressures are listed in the manual for the test bench. See Special Instruction, SEHS8200. These screens still apply to this data. Every data set (DMXXXX screen) contains data for many injection pump and governor group part numbers. The data is sorted by the profile or geometry of the basic cam and the lowest level part number of the plunger and barrel group. Most part numbers with the same basic cam, plunger, and barrel groups use the same data.Pages of data in the DATA SETS are arranged in descending pump rpm. Five or six rpm choices are listed. When the