Information injection-pump assembly

ZEXEL

106675-4220

1066754220

KOMATSU

6211711680

6211711680

Rating:

Cross reference number

ZEXEL

106675-4220

1066754220

KOMATSU

6211711680

6211711680

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-3420

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.3

4.25

4.35

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

8.9

Pump speed

r/min

1050

1050

1050

Average injection quantity

mm3/st.

145.5

141.5

149.5

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

5.1+-0.5

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

18

16.5

19.5

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

D

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

200

190

210

Fixing the lever

*

Rack limit

*

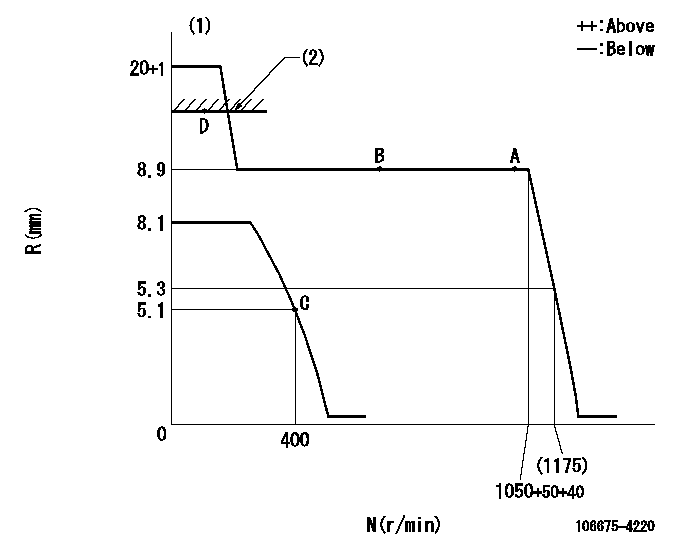

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Notch fixed: K

(2)RACK LIMIT

----------

K=25

----------

----------

K=25

----------

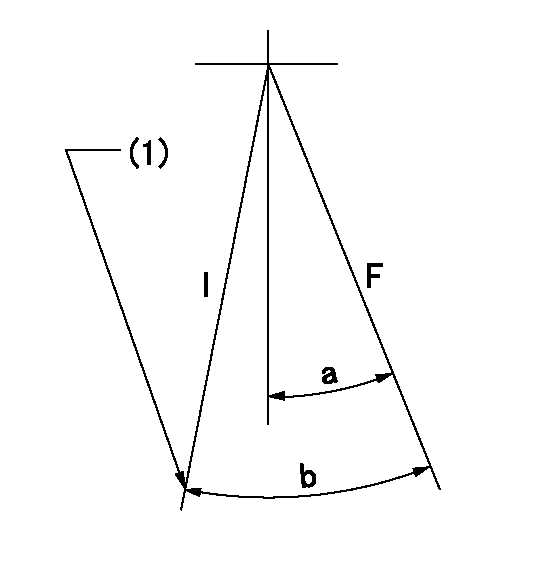

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=20deg+-5deg b=(28deg)+-5deg

----------

----------

a=20deg+-5deg b=(28deg)+-5deg

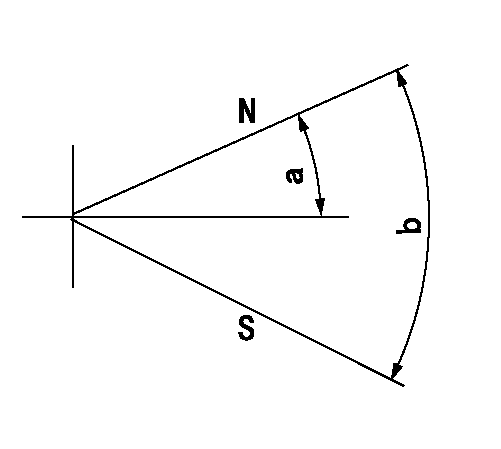

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=26.5deg+-5deg b=53deg+-5deg

----------

----------

a=26.5deg+-5deg b=53deg+-5deg

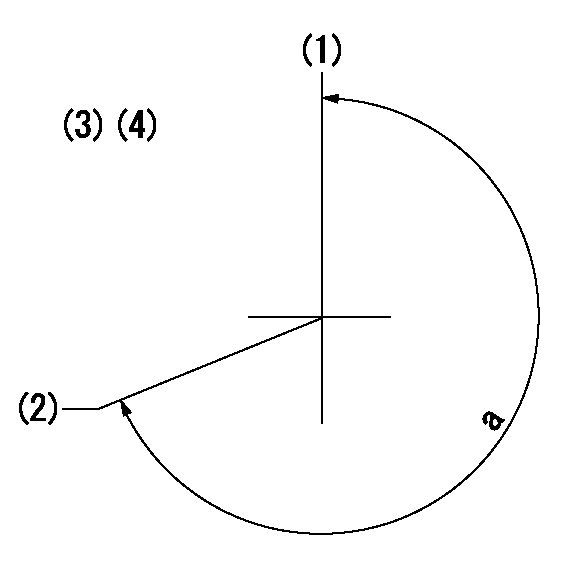

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(260deg)

----------

----------

a=(260deg)

Information:

Problem 4

The starting motor remains engaged or the starting motor continues to run after the engine is running.

Check the components of the starting circuit.

Measure the voltages at terminal (TS-26) of the junction box while the engine is running.Result

The voltage at the terminal is zero volts.The problem is in the starting motor (SM), the pinion solenoid (PS), or the magnetic switch (MS). Repair the faulty component. STOP.

The voltage at the terminal is between 15 volts and 32 volts.The START terminals of the start/stop switch are normally closed. This is normal for an automatic start system. In a manual start system, the switches should be normally open. The switch is on terminals (SSS-1) and (SSS-2) for a normal start/stop switch. Repair the faulty switch. STOP.Problem 5

The engine shutdown occurs after the engine runs for more than 3 minutes.

Check the protection switches.

Remove the jumper that is between terminals (TS-9) and (TS-10) of the junction box.

If the engine is equipped with a low oil pressure indicator, disconnect the diode that is between terminals (TS-8) and (TS-10). The cathode lead of the diode should be connected to terminal (TS-10).

If the engine is equipped with a low oil pressure indicator, ensure that a jumper is not installed between terminals (TS-8) and (TS-9).

Start the engine.

Reconnect the jumper that is between terminals (TS-9) and (TS-10) of the junction box after the test is completed.Result

The engine starts and the engine runs.The problem is in the oil pressure switch or the water temperature contactor switch. Go to Step 5 of "Problem 1".

The engine starts but engine shutdown occurs immediately.Go to Step 1 of "Problem 3".

The engine starts and the engine runs but engine shutdown occurs after the engine runs for more than 3 minutes.Go to Step 2.

The engine cranks but the engine does not start.Go to Step 1 of "Problem 1".

Check the start/stop switch and slave relay (SR1).

Disconnect the wire in the junction box that connects terminal (SR1-85) of the slave relay (SR1) to terminal (TD-7) of the time delay relay (TD).

Crank the engine. Activate the emergency stop switch, if necessary.Result

The engine starts and the engine runs.The start/stop switch has a short circuit or a wiring problem is causing a voltage at terminal (TD-7). Reconnect the wire to the terminal. STOP.

Engine shutdown still occurs after several minutes.The contacts of (SR1) periodically close. The problem may also be with the governor or the fuel supply to the engine. Refer to the Engine Service Manual. If a 2301A Electric Governor is used, the SR1 contacts may be opening. Refer to 2301A Electric Governor Service Manual, SENR3585. Test SR1. Refer to Testing and Adjusting, "Slave Relay Test".Problem 6

Engine shutdown does not occur when a fault is detected.

Check the protection switches and the crank terminate switch of the electronic speed switch.

Reset circuit breaker (CB7).

Start the engine and run the engine at low idle.

Contact with electrical components can cause injury or death.Remove all jewelry and avoid contact with electrical components. Use properly insulated tools when working on the junction box of an

The starting motor remains engaged or the starting motor continues to run after the engine is running.

Check the components of the starting circuit.

Measure the voltages at terminal (TS-26) of the junction box while the engine is running.Result

The voltage at the terminal is zero volts.The problem is in the starting motor (SM), the pinion solenoid (PS), or the magnetic switch (MS). Repair the faulty component. STOP.

The voltage at the terminal is between 15 volts and 32 volts.The START terminals of the start/stop switch are normally closed. This is normal for an automatic start system. In a manual start system, the switches should be normally open. The switch is on terminals (SSS-1) and (SSS-2) for a normal start/stop switch. Repair the faulty switch. STOP.Problem 5

The engine shutdown occurs after the engine runs for more than 3 minutes.

Check the protection switches.

Remove the jumper that is between terminals (TS-9) and (TS-10) of the junction box.

If the engine is equipped with a low oil pressure indicator, disconnect the diode that is between terminals (TS-8) and (TS-10). The cathode lead of the diode should be connected to terminal (TS-10).

If the engine is equipped with a low oil pressure indicator, ensure that a jumper is not installed between terminals (TS-8) and (TS-9).

Start the engine.

Reconnect the jumper that is between terminals (TS-9) and (TS-10) of the junction box after the test is completed.Result

The engine starts and the engine runs.The problem is in the oil pressure switch or the water temperature contactor switch. Go to Step 5 of "Problem 1".

The engine starts but engine shutdown occurs immediately.Go to Step 1 of "Problem 3".

The engine starts and the engine runs but engine shutdown occurs after the engine runs for more than 3 minutes.Go to Step 2.

The engine cranks but the engine does not start.Go to Step 1 of "Problem 1".

Check the start/stop switch and slave relay (SR1).

Disconnect the wire in the junction box that connects terminal (SR1-85) of the slave relay (SR1) to terminal (TD-7) of the time delay relay (TD).

Crank the engine. Activate the emergency stop switch, if necessary.Result

The engine starts and the engine runs.The start/stop switch has a short circuit or a wiring problem is causing a voltage at terminal (TD-7). Reconnect the wire to the terminal. STOP.

Engine shutdown still occurs after several minutes.The contacts of (SR1) periodically close. The problem may also be with the governor or the fuel supply to the engine. Refer to the Engine Service Manual. If a 2301A Electric Governor is used, the SR1 contacts may be opening. Refer to 2301A Electric Governor Service Manual, SENR3585. Test SR1. Refer to Testing and Adjusting, "Slave Relay Test".Problem 6

Engine shutdown does not occur when a fault is detected.

Check the protection switches and the crank terminate switch of the electronic speed switch.

Reset circuit breaker (CB7).

Start the engine and run the engine at low idle.

Contact with electrical components can cause injury or death.Remove all jewelry and avoid contact with electrical components. Use properly insulated tools when working on the junction box of an