Information injection-pump assembly

ZEXEL

106673-7941

1066737941

MITSUBISHI

ME359605

me359605

Rating:

Service parts 106673-7941 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

10.

NOZZLE AND HOLDER ASSY

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

13.

NOZZLE-HOLDER

14.

NOZZLE

15.

NOZZLE SET

Include in #1:

106673-7941

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

106673-7941

1066737941

MITSUBISHI

ME359605

me359605

Zexel num

Bosch num

Firm num

Name

106673-7941

ME359605 MITSUBISHI

INJECTION-PUMP ASSEMBLY

6D24

6D24

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-4620

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.8

4.75

4.85

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

7.4

Pump speed

r/min

700

700

700

Each cylinder's injection qty

mm3/st.

104.5

101.9

107.1

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

5.1+-0.5

Pump speed

r/min

225

225

225

Each cylinder's injection qty

mm3/st.

14.5

12.3

16.7

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(7.4)

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

104.5

103.5

105.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1(7.4)

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

121.5

113.5

129.5

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

F

Rack position

9.7+-0.5

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

110

90

130

Fixing the lever

*

Remarks

After startup boost setting

After startup boost setting

Timer adjustment

Pump speed

r/min

850--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

(800)

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1000

Advance angle

deg.

4

3.5

4.5

Remarks

Finish

Finish

Test data Ex:

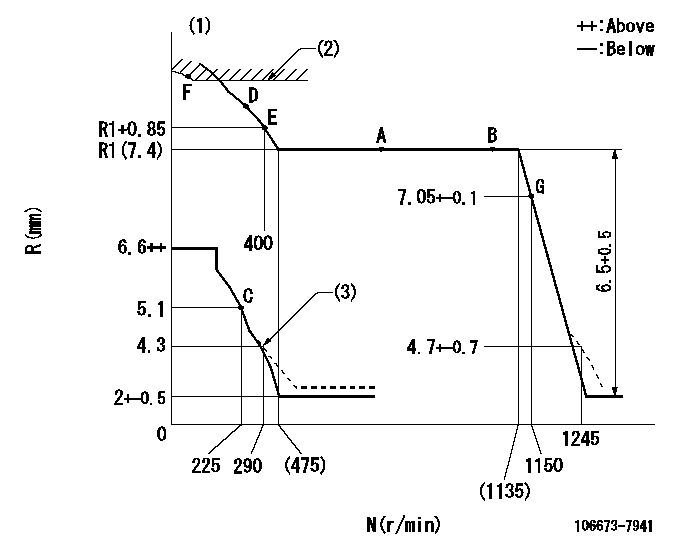

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Tolerance for racks not indicated: +-0.05mm.

(2)Excess fuel setting for starting: SXL (N = N1)

(3)Damper spring setting

----------

SXL=9.3+0.2mm N1=225r/min

----------

----------

SXL=9.3+0.2mm N1=225r/min

----------

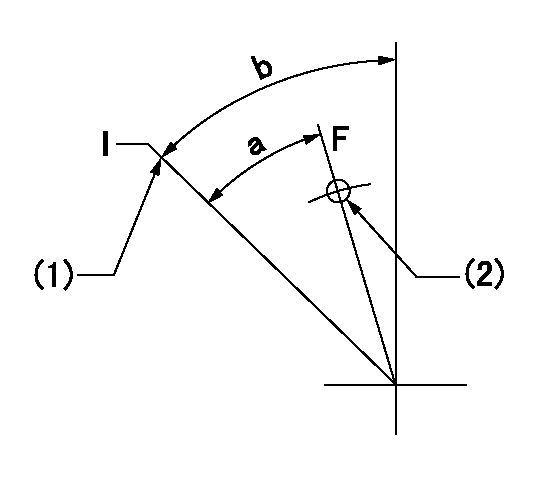

Speed control lever angle

F:Full speed

----------

----------

a=(17deg)+-5deg

----------

----------

a=(17deg)+-5deg

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

(2)Use the hole at R = aa

----------

aa=55mm

----------

a=20.5deg+-3deg b=24deg+-5deg

----------

aa=55mm

----------

a=20.5deg+-3deg b=24deg+-5deg

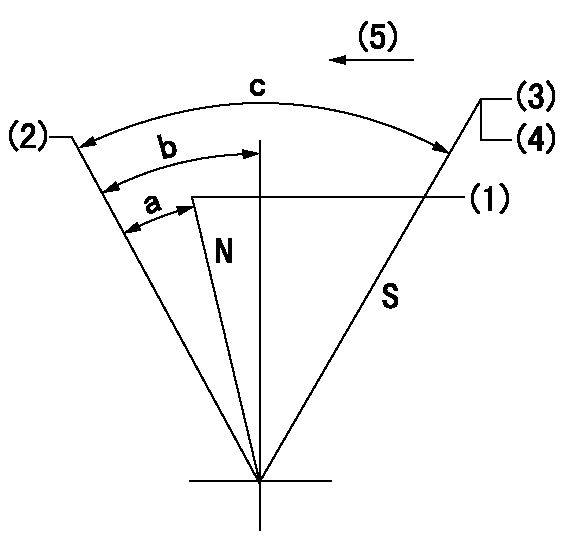

Stop lever angle

N:Engine manufacturer's normal use

S:Stop the pump.

(1)Rack position = aa

(2)Free (at delivery)

(3)Rack position bb

(4)Stopper bolt setting

(5)Drive side

----------

aa=(18.7)mm bb=3-0.5mm

----------

a=15deg+-5deg b=25deg+-5deg c=59deg+7deg-5deg

----------

aa=(18.7)mm bb=3-0.5mm

----------

a=15deg+-5deg b=25deg+-5deg c=59deg+7deg-5deg

0000001501 MICRO SWITCH

Adjustment of the micro-switch

Adjust the bolt to obtain the following lever position when the micro-switch is ON.

(1)Speed N1

(2)Rack position Ra

----------

N1=325r/min Ra=4.8+-0.1mm

----------

----------

N1=325r/min Ra=4.8+-0.1mm

----------

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=15deg

----------

a=(5deg)

----------

aa=15deg

----------

a=(5deg)

Information:

PARTS NEEDED

Qty

Part Number Description

*******Group 1*******

1 4716029 MTG GP-INJECTOR

1 ENGSOFTWARE ENGINE SOFTWARE

In order to allow equitable parts availability to all participating dealers, please limit your initial parts order to not exceed 21% of dealership population. This is an initial order recommendation only, and the ultimate responsibility for ordering the total number of parts needed to satisfy the program lies with the dealer.

*******Group 2*******

1 4716029 MTG GP-INJECTOR

1 ENGSOFTWARE ENGINE SOFTWARE

In order to allow equitable parts availability to all participating dealers, please limit your initial parts order to not exceed 21% of dealership population. This is an initial order recommendation only, and the ultimate responsibility for ordering the total number of parts needed to satisfy the program lies with the dealer.

ACTION REQUIRED

Before Failure:

If the engine software is not the latest version, update the Engine Software first.

If needed, update the engine software with the latest available in SIS Web.

For flash programming of the ECM software, refer to Troubleshooting "ECM Software - Install".

After Failure:

Ensure the appropriate steps have been followed when diagnosing a DEF injector failure. Refer to UENR0662.

If it is determined that replacement of DEF injector is required, refer to Disassembly and Assembly Manual - Diesel Exhaust Fluid Injector - Remove and Install.

SERVICE CLAIM ALLOWANCES

Product smu/age whichever comes first Caterpillar Dealer Suggested Customer Suggested

Parts % Labor Hrs% Parts % Labor Hrs% Parts % Labor Hrs%

*******Group 1*******

0-5000 hrs,

0-60 mo 100.0% 100.0% 0.0% 0.0% 0.0% 0.0%

This is a 2.0-hour job for Group 1

Product smu/age whichever comes first Caterpillar Dealer Suggested Customer Suggested

Parts % Labor Hrs% Parts % Labor Hrs% Parts % Labor Hrs%

*******Group 2*******

0-5000 hrs,

0-60 mo 100.0% 100.0% 0.0% 0.0% 0.0% 0.0%

This is a 2.0-hour job for Group 2

PARTS DISPOSITION

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

Have questions with 106673-7941?

Group cross 106673-7941 ZEXEL

Mitsubishi

Mitsubishi

Mitsubishi

Mitsubishi

106673-7941

ME359605

INJECTION-PUMP ASSEMBLY

6D24

6D24