Information injection-pump assembly

ZEXEL

106673-7460

1066737460

Rating:

Cross reference number

ZEXEL

106673-7460

1066737460

Zexel num

Bosch num

Firm num

Name

106673-7460

INJECTION-PUMP ASSEMBLY

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8250

Bosch type code

1 688 901 101

Nozzle

105780-0120

Bosch type code

1 688 901 990

Nozzle holder

105780-2190

Opening pressure

MPa

20.7

Opening pressure

kgf/cm2

211

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131425-0220

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.9

3.85

3.95

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

13.4

Pump speed

r/min

700

700

700

Each cylinder's injection qty

mm3/st.

161.5

157.5

165.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

Z

Rack position

8+-0.5

Pump speed

r/min

430

430

430

Each cylinder's injection qty

mm3/st.

21

17.8

24.2

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(13.4)

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

161.5

160.5

162.5

Basic

*

Fixing the lever

*

Boost pressure

kPa

29.3

29.3

Boost pressure

mmHg

220

220

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+1.1

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

154

150

158

Fixing the lever

*

Boost pressure

kPa

29.3

29.3

Boost pressure

mmHg

220

220

Injection quantity adjustment_05

Adjusting point

C

Rack position

(R1-0.85

)

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

156

150

162

Fixing the lever

*

Boost pressure

kPa

29.3

29.3

Boost pressure

mmHg

220

220

Boost compensator adjustment

Pump speed

r/min

250

250

250

Rack position

R2-1.65

Boost pressure

kPa

6.7

5.4

8

Boost pressure

mmHg

50

40

60

Boost compensator adjustment_02

Pump speed

r/min

250

250

250

Rack position

R2[R1-1.

6]

Boost pressure

kPa

16

16

16

Boost pressure

mmHg

120

120

120

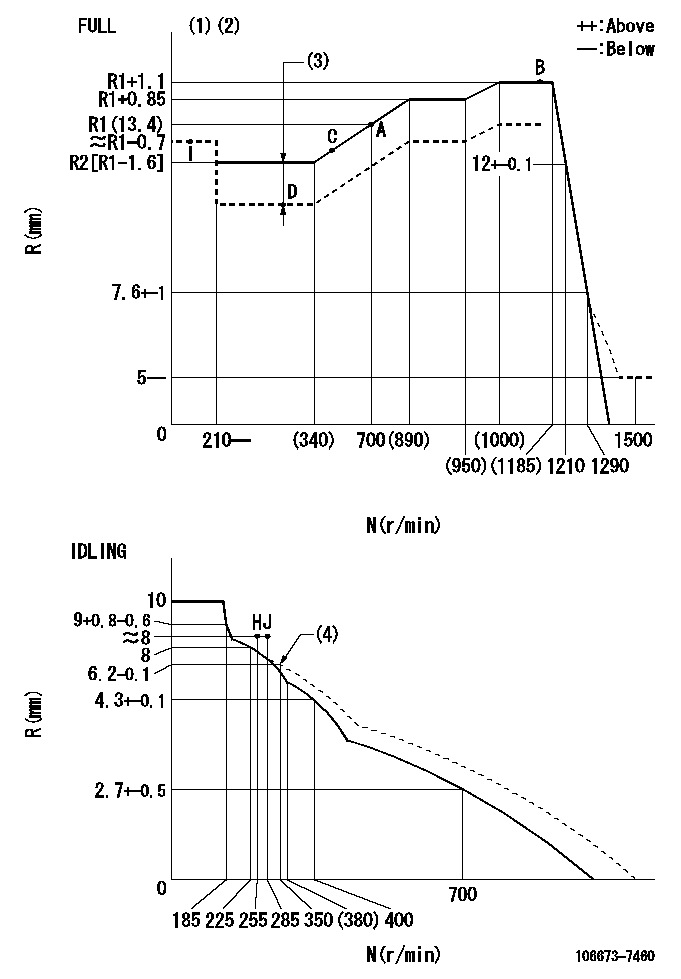

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Boost compensator stroke: BCL

(4)Damper spring setting

----------

T1=AD81 BCL=1.65+-0.1mm

----------

----------

T1=AD81 BCL=1.65+-0.1mm

----------

Timer adjustment

(1)Adjusting range

(2)Step response time

(N): Speed of the pump

(L): Load

(theta) Advance angle

(Srd1) Step response time 1

(Srd2) Step response time 2

1. Adjusting conditions for the variable timer

(1)Adjust the clearance between the pickup and the protrusion to L.

----------

L=1-0.2mm N2=800r/min C2=(10)deg t1=2.5--sec. t2=2.5--sec.

----------

N1=750++r/min P1=0kPa(0kgf/cm2) P2=392kPa(4kgf/cm2) C1=10+-0.3deg R01=0/4load R02=4/4load

----------

L=1-0.2mm N2=800r/min C2=(10)deg t1=2.5--sec. t2=2.5--sec.

----------

N1=750++r/min P1=0kPa(0kgf/cm2) P2=392kPa(4kgf/cm2) C1=10+-0.3deg R01=0/4load R02=4/4load

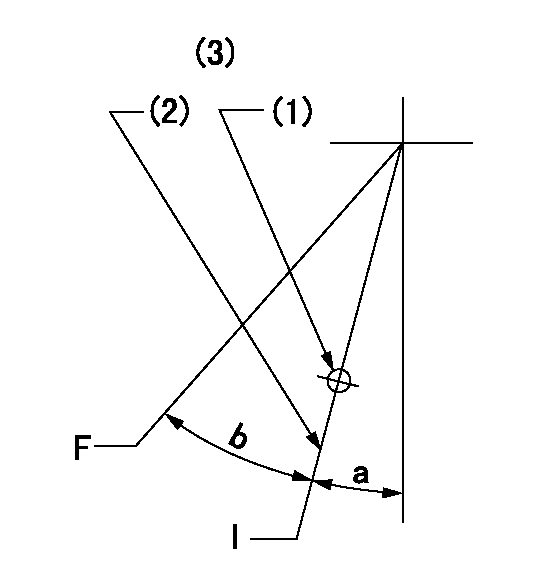

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt setting

(3)Viewed from feed pump side.

----------

aa=37.5mm

----------

a=2deg+-5deg b=37deg+-3deg

----------

aa=37.5mm

----------

a=2deg+-5deg b=37deg+-3deg

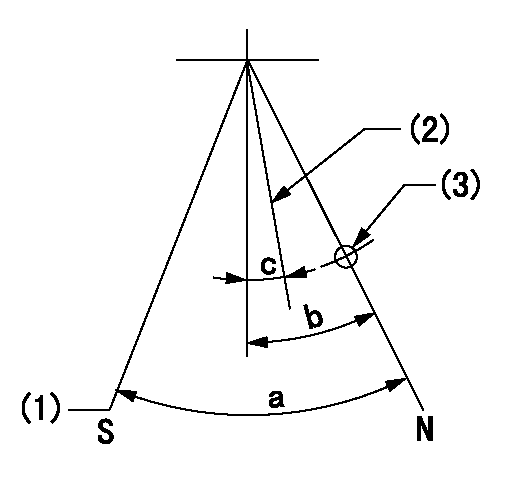

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)At pump speed aa and rack position bb, set the stopper bolt. (Confirm non-injection.)

(2)Normal engine position (equivalent to R = cc).

(3)Use the hole above R = dd

----------

aa=1100r/min bb=3.5+-0.3mm cc=18mm dd=54mm

----------

a=40deg+-5deg b=29.5deg+-5deg c=(20.5deg)

----------

aa=1100r/min bb=3.5+-0.3mm cc=18mm dd=54mm

----------

a=40deg+-5deg b=29.5deg+-5deg c=(20.5deg)

0000001501 MICRO SWITCH

Adjustment of the micro-switch

Adjust the bolt to obtain the following lever position when the micro-switch is ON.

(1)Speed N1

(2)Rack position Ra

----------

N1=325r/min Ra=7.6+-0.1mm

----------

----------

N1=325r/min Ra=7.6+-0.1mm

----------

0000001601 RACK SENSOR

(VR) measurement voltage

(I) Part number of the control unit

(G) Apply red paint.

(H): End surface of the pump

1. Rack sensor adjustment (-0620)

(1)Fix the speed control lever at the full position

(2)Set the speed to N1 r/min.

(If the boost compensator is provided, apply boost pressure.)

(3)Adjust the bobbin (A) so that the rack sensor's output voltage is VR+-0.01.

(4)At that time, rack position must be Ra.

(5)Apply G at two places.

Connecting part between the joint (B) and the nut (F)

Connecting part between the joint (B) and the end surface of the pump (H)

----------

N1=1100r/min Ra=R1(13.4)+1.1mm

----------

----------

N1=1100r/min Ra=R1(13.4)+1.1mm

----------

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=5deg

----------

a=(2deg)

----------

aa=5deg

----------

a=(2deg)

Information:

Start By:a. remove automatic timing advanceb. remove oil panc. remove water pumpd. remove crankshaft front seal and wear sleeve 1. Disconnect clip (1) for the wiring harness.2. Remove connector (2) from the clip. 3. Fasten Tooling (A) and a hoist to the timing gear cover. The weight of the timing gear cover is 18 kg (40 lb).4. Use Tooling (B) to remove studs (3).5. Move fuel overflow tube (4) out of the way.6. Remove cover (5) and the gasket.7. Disconnect all wiring harness clips from the timing gear housing, and move the wiring harness out of the way.8. Remove the bolts that hold the timing gear cover to the cylinder block, and remove the timing gear cover.9. Remove the gasket for the timing gear cover.10. Thoroughly clean the gasket surface of the cylinder block and the timing gear cover. Be careful not to scratch or mar the gasket surface of the aluminum timing gear cover.Install Timing Gear Cover

1. Install new O-ring seal (1) on the fuel injection pump housing. Put clean engine oil on the O-ring seal.2. Put new gasket (2) in position on the cylinder block. Engage the gasket with the two dowels. Use clean 2S-3230 Bearing Lubricant to hold the gasket in place on the cylinder block. 3. Put the timing gear cover in position on the dowels. Install the bolts that hold the timing gear cover to the cylinder block.4. Install cover (6), and a new gasket.5. Connect the wiring harness clips to the timing gear housing.6. Connect the clip that holds fuel overflow tube (5).7. Use Tooling (B) to install studs (3).8. Remove Tooling (A).9. Put 5P-3413 Pipe Sealant with "Teflon" on the threads of stud (4). Use Tool (B) to install stud (4) to a height of 28.96 mm (1.140 in).10. Install the clip that holds the wiring harness.11. Install the connector in the clip.12. Trim gasket (2) even with the oil pan surface of the cylinder block and timing gear cover.End By:a. install crankshaft front seal and wear sleeveb. install water pumpc. install oil pand. install automatic timing advance

1. Install new O-ring seal (1) on the fuel injection pump housing. Put clean engine oil on the O-ring seal.2. Put new gasket (2) in position on the cylinder block. Engage the gasket with the two dowels. Use clean 2S-3230 Bearing Lubricant to hold the gasket in place on the cylinder block. 3. Put the timing gear cover in position on the dowels. Install the bolts that hold the timing gear cover to the cylinder block.4. Install cover (6), and a new gasket.5. Connect the wiring harness clips to the timing gear housing.6. Connect the clip that holds fuel overflow tube (5).7. Use Tooling (B) to install studs (3).8. Remove Tooling (A).9. Put 5P-3413 Pipe Sealant with "Teflon" on the threads of stud (4). Use Tool (B) to install stud (4) to a height of 28.96 mm (1.140 in).10. Install the clip that holds the wiring harness.11. Install the connector in the clip.12. Trim gasket (2) even with the oil pan surface of the cylinder block and timing gear cover.End By:a. install crankshaft front seal and wear sleeveb. install water pumpc. install oil pand. install automatic timing advance

Have questions with 106673-7460?

Group cross 106673-7460 ZEXEL

Mitsubishi

Mitsubishi

Mitsubishi

Mitsubishi

106673-7460

INJECTION-PUMP ASSEMBLY