Information injection-pump assembly

BOSCH

9 400 617 329

9400617329

ZEXEL

106673-7150

1066737150

MITSUBISHI

ME151542

me151542

Rating:

Cross reference number

BOSCH

9 400 617 329

9400617329

ZEXEL

106673-7150

1066737150

MITSUBISHI

ME151542

me151542

Zexel num

Bosch num

Firm num

Name

106673-7150

9 400 617 329

ME151542 MITSUBISHI

INJECTION-PUMP ASSEMBLY

6D22T3 * K 14CA INJECTION PUMP ASSY PE6P,6PD PE

6D22T3 * K 14CA INJECTION PUMP ASSY PE6P,6PD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-4620

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.8

4.75

4.85

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

10.3

Pump speed

r/min

650

650

650

Each cylinder's injection qty

mm3/st.

170.5

166.2

174.8

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

F

Rack position

4.6+-0.5

Pump speed

r/min

500

500

500

Each cylinder's injection qty

mm3/st.

10

8.8

11.2

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(10.3)

Pump speed

r/min

650

650

650

Average injection quantity

mm3/st.

170.5

169.5

171.5

Basic

*

Fixing the lever

*

Boost pressure

kPa

45.3

45.3

Boost pressure

mmHg

340

340

Injection quantity adjustment_04

Adjusting point

B

Rack position

R2(R1-1)

Pump speed

r/min

1075

1075

1075

Average injection quantity

mm3/st.

161

156.9

165.1

Difference in delivery

mm3/st.

8.2

8.2

8.2

Fixing the lever

*

Boost pressure

kPa

45.3

45.3

Boost pressure

mmHg

340

340

Injection quantity adjustment_05

Adjusting point

D

Rack position

R3(R1-2.

4)

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

117

115

119

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_06

Adjusting point

C

Rack position

5.3+-0.5

Pump speed

r/min

225

225

225

Each cylinder's injection qty

mm3/st.

15

13.2

16.8

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Remarks

(check)

(check)

Injection quantity adjustment_07

Adjusting point

E

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

85

65

105

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_08

Adjusting point

F

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

160

150

170

Fixing the lever

*

Boost pressure

kPa

80

80

Boost pressure

mmHg

600

600

Rack limit

*

Boost compensator adjustment

Pump speed

r/min

600

600

600

Rack position

R3(R1-2.

4)

Boost pressure

kPa

3.3

3.3

5.3

Boost pressure

mmHg

25

25

40

Boost compensator adjustment_02

Pump speed

r/min

600

600

600

Rack position

R1-0.1

Boost pressure

kPa

21.3

20

22.6

Boost pressure

mmHg

160

150

170

Boost compensator adjustment_03

Pump speed

r/min

600

600

600

Rack position

(10.4)

Boost pressure

kPa

32

32

32

Boost pressure

mmHg

240

240

240

Timer adjustment

Pump speed

r/min

900--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

850

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1075

Remarks

Measure the actual advance angle.

Measure the actual advance angle.

Timer adjustment_04

Pump speed

r/min

-

Advance angle

deg.

1.5

1

2

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

Test data Ex:

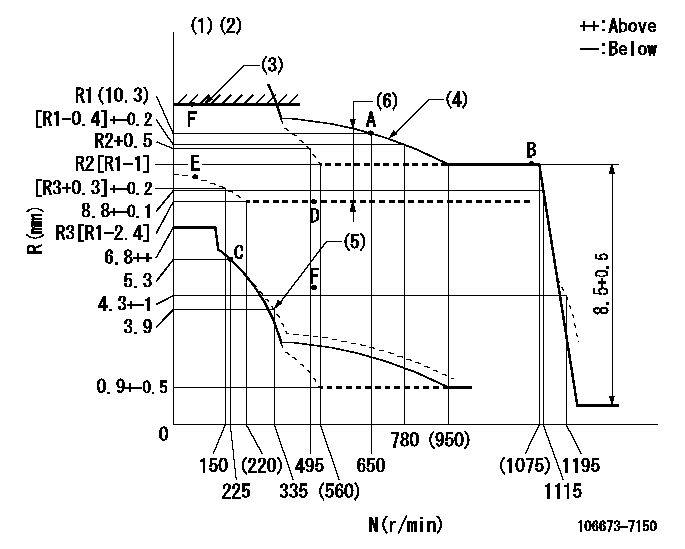

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Tolerance for racks not indicated: +-0.05mm.

(2)RACK LIMIT

(3)Boost compensator cancel stroke: BSL

(4)The torque control spring must does not have a set force.

(5)Damper spring setting

(6)Boost compensator stroke: BCL (N = N1)

----------

BSL=3.8mm BCL=(2.5)mm N1=600r/min

----------

----------

BSL=3.8mm BCL=(2.5)mm N1=600r/min

----------

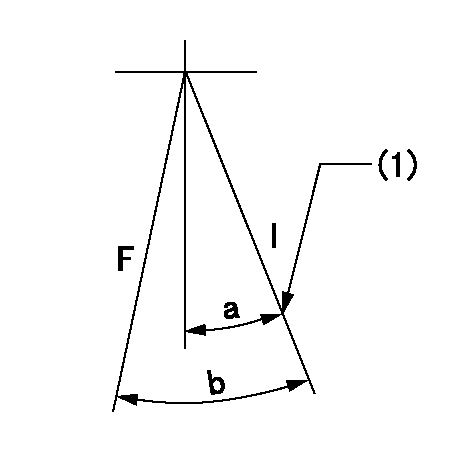

Speed control lever angle

F:Full speed

----------

----------

a=17deg+-5deg

----------

----------

a=17deg+-5deg

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=28deg+-5deg b=31deg+-3deg

----------

----------

a=28deg+-5deg b=31deg+-3deg

Stop lever angle

N:Engine manufacturer's normal use

S:Stop the pump.

(1)Rack position = aa

(2)Stopper bolt setting

(3)Rack position bb

(4)Free (at delivery)

----------

aa=3-0.5mm bb=13.3mm

----------

a=28.5deg+-5deg b=(38deg) c=1.5deg+7deg-5deg

----------

aa=3-0.5mm bb=13.3mm

----------

a=28.5deg+-5deg b=(38deg) c=1.5deg+7deg-5deg

0000001501 MICRO SWITCH

Adjustment of the micro-switch

Adjust the bolt to obtain the following lever position when the micro-switch is ON.

(1)Speed N1

(2)Rack position Ra

----------

N1=325r/min Ra=5+-0.1mm

----------

----------

N1=325r/min Ra=5+-0.1mm

----------

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(7deg)

----------

----------

a=(7deg)

Information:

Do not put oil on the bearings until the bearing clearance has been checked.1. Install bearings (1) in the connecting rods they were removed from. Make sure the tab in each bearing is in alignment with the notch in each connecting rod.2. Install bearings (2) in the cylinder block. Make sure the tab in each bearing is in alignment with the notch in the cylinder block. 3. Install pin (3) in the end of the crankshaft. Install the pin so that it extends a maximum of 6.4 mm (.252 in) above the surface. 4. Install the dowel in the crankshaft that puts gear (4) in the correct position. Install the dowel so that it extends 4.1 0.5 mm (.161 .020 in) above the surface of the crankshaft.5. Heat gear (4) to a maximum temperature of 233° C (451° F). Gear (4) must be installed on the crankshaft with the "V" timing mark toward the outside.6. Install gear (4) on the crankshaft. Make sure the notch in the gear is in alignment with the dowel on the crankshaft. The dimension from the rear face of the gear to the front face of the crankshaft must be 45.54 0.25 mm (1.793 .010 in). 7. Fasten Tooling (A) and a hoist to the crankshaft (5) as shown. Install the crankshaft in the engine. The weight of the crankshaft is approximately 131 kg (290 lb). 8. Make sure that "V" mark (6) on the crankshaft is in alignment with "V" mark (7) on the idler gear. The side of each thrust plate (8) with the words "BLOCK SIDE" must be installed with this side toward the cylinder block.9. Put clean oil on thrust plates (8). Install thrust plates (8) next to the center main bearings. Do not put oil on bearings (9) until the bearing clearances have been checked.10. Put bearings (9) in their original position in crankshaft main bearing caps (10).11. Check the crankshaft main bearing clearance with Plastigage as follows:a. Put a piece of Plastigage between the crankshaft bearing journal surface and bearing (9).b. Install the crankshaft main bearing caps (10) with the arrow on each cap toward the front of cylinder block. Each crankshaft main bearing cap has a number on the bottom surface and must be installed in the same position as the correct number on the left side of the cylinder block.c. Put 2P-2506 Thread Lubricant on the threads of the cap bolts. Install the cap bolts finger tight.d. Tighten the bolts on the tab end of the caps first to a torque of 258 14 N m (190 10 lb ft).e. Tighten the bolts on the other end of the caps to a torque of 258 14 N m (190 10 lb ft).

Do not use an impact wrench to tighten the bolts the additional 120 degrees.

f. Put a mark across the bolt head and cap. Tighten the bolts opposite the tab end of the cap

Do not use an impact wrench to tighten the bolts the additional 120 degrees.

f. Put a mark across the bolt head and cap. Tighten the bolts opposite the tab end of the cap

Have questions with 106673-7150?

Group cross 106673-7150 ZEXEL

Mitsubishi

Mitsubishi

Mitsubishi

106673-7150

9 400 617 329

ME151542

INJECTION-PUMP ASSEMBLY

6D22T3

6D22T3