Information injection-pump assembly

BOSCH

9 400 617 325

9400617325

ZEXEL

106673-7110

1066737110

MITSUBISHI

ME151383

me151383

Rating:

Cross reference number

BOSCH

9 400 617 325

9400617325

ZEXEL

106673-7110

1066737110

MITSUBISHI

ME151383

me151383

Zexel num

Bosch num

Firm num

Name

106673-7110

9 400 617 325

ME151383 MITSUBISHI

INJECTION-PUMP ASSEMBLY

6D22T3 K 14CA INJECTION PUMP ASSY PE6P,6PD PE

6D22T3 K 14CA INJECTION PUMP ASSY PE6P,6PD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-8020

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.9

3.85

3.95

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

10

Pump speed

r/min

600

600

600

Each cylinder's injection qty

mm3/st.

169.5

165.3

173.7

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

Z

Rack position

4.3+-0.5

Pump speed

r/min

440

440

440

Each cylinder's injection qty

mm3/st.

20.5

18

23

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(10)

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

169.5

167.5

171.5

Basic

*

Fixing the lever

*

Boost pressure

kPa

93.3

93.3

Boost pressure

mmHg

700

700

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+0.75

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

146.5

138.3

154.7

Fixing the lever

*

Boost pressure

kPa

93.3

93.3

Boost pressure

mmHg

700

700

Injection quantity adjustment_05

Adjusting point

E

Rack position

R1-2.6

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

112.5

108.7

116.3

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_06

Adjusting point

F

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

60

40

80

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

600

600

600

Rack position

R1-2.6

Boost pressure

kPa

3.3

3.3

5.3

Boost pressure

mmHg

25

25

40

Boost compensator adjustment_02

Pump speed

r/min

600

600

600

Rack position

R1-1.55

Boost pressure

kPa

23.3

22

24.6

Boost pressure

mmHg

175

165

185

Boost compensator adjustment_03

Pump speed

r/min

600

600

600

Rack position

R1(10)

Boost pressure

kPa

80

80

80

Boost pressure

mmHg

600

600

600

Timer adjustment

Pump speed

r/min

900--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

850

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1100

Advance angle

deg.

1.5

1

2

Remarks

Finish

Finish

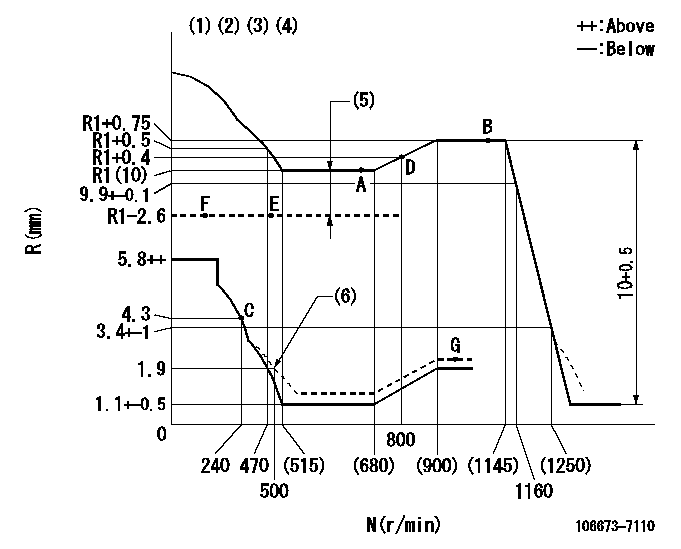

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Lever ratio: RT

(2)Target shim dimension: TH

(3)Tolerance for racks not indicated: +-0.05mm.

(4)Boost compensator cancel stroke: BSL

(5)Boost compensator stroke: BCL

(6)Damper spring setting

----------

RT=1 TH=2.1mm BSL=4mm BCL=2.6+-0.1mm

----------

----------

RT=1 TH=2.1mm BSL=4mm BCL=2.6+-0.1mm

----------

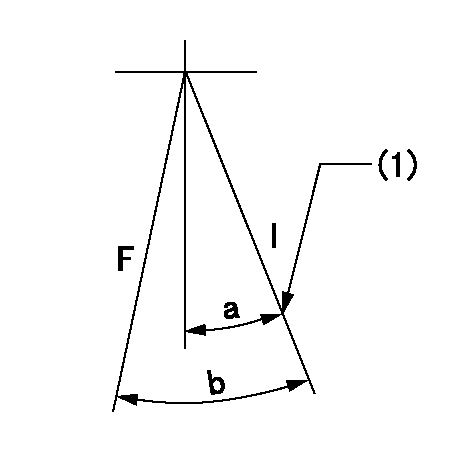

Speed control lever angle

F:Full speed

----------

----------

a=17deg+-5deg

----------

----------

a=17deg+-5deg

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=28deg+-5deg b=32deg+-3deg

----------

----------

a=28deg+-5deg b=32deg+-3deg

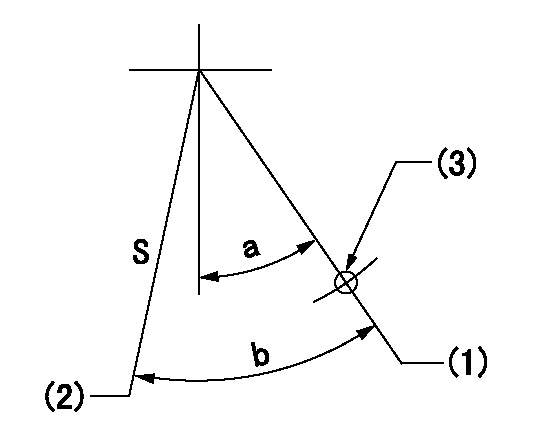

Stop lever angle

S:Stop the pump.

(1)Free (at delivery)

(2)Rack position = aa (non-injection rack position). Set the stopper bolt at speed = bb.

(3)Use the hole above R = cc

----------

aa=2.9-0.5mm bb=240r/min cc=37mm

----------

a=38deg+-5deg b=40deg+7deg-5deg

----------

aa=2.9-0.5mm bb=240r/min cc=37mm

----------

a=38deg+-5deg b=40deg+7deg-5deg

0000001501 MICRO SWITCH

Adjustment of the micro-switch

Adjust the bolt to obtain the following lever position when the micro-switch is ON.

(1)Speed N1

(2)Rack position Ra

----------

N1=325r/min Ra=4.3+-0.1mm

----------

----------

N1=325r/min Ra=4.3+-0.1mm

----------

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=9deg

----------

a=(3deg)

----------

aa=9deg

----------

a=(3deg)

Information:

Start By:a. remove timing gear coverb. remove push rods and valve lifters 1. Remove air compressor outlet hose (1). (Not applicable).2. Remove air compressor air inlet tube (3). (Not applicable).3. Remove air compressor coolant outlet tube (4). (Not applicable)4. Remove turbocharger oil return tube (2). 5. Use Tooling (A) to remove studs (5).6. Turn the flywheel with Tool (B), and remove each bolt (6) as it becomes accessible.7. Turn the flywheel with Tool (B) until the "V" marks on the front timing gears are in alignment.8. Install Tooling (C) through the holes for studs (5) into camshaft rear gear (7).

Tooling (C) must be used to prevent the loss of rear balance weight timing and to keep the camshaft rear gear in place when the camshaft is removed.

9. Tighten Tooling (C) evenly to remove the camshaft rear gear from the camshaft. 10. Remove thrust plate (8).

Be careful not to damage the camshaft bearings. Do not pry the camshaft out of the cylinder block. If resistance to camshaft removal occurs, turn the camshaft so the lobes will align the bearing journals with the camshaft bearing bores.

11. Carefully remove the camshaft and gear (9) from the cylinder block.12. If removal of the camshaft gear is necessary, place the camshaft and gear in a hydraulic press. Place Tool (D) over the camshaft, and press against it to remove the camshaft from the gear.

Be careful not to scratch or mar the finished surfaces of the camshaft.

13. Remove the key from the camshaft.14. If dowel removal is necessary, use Tool (E) to remove the dowel.Install Camshaft

1. Install the key in the camshaft. Be sure the key is seated in the camshaft.2. Install the pin in the rear of the camshaft. Install the pin to a height of 8.51 to 9.01 mm (.335 to .355 in).3. Heat the camshaft drive gear to a maximum temperature of 204° C (400° F), align the groove in the drive gear with the key in the camshaft, and install the camshaft drive gear with the timing marks away from the camshaft.4. Put clean engine oil on the camshaft bearing journals and lobes.5. Carefully install the camshaft into the cylinder block. Do not force the camshaft into position. If resistance to camshaft installation occurs, turn the camshaft so the lobes will align the bearing journals with the camshaft bearing bores. 6. Align the "V" marks on camshaft drive gear (2) and idler gear (3).7. Install thrust plate (1) to hold the camshaft and camshaft drive gear (2) in the cylinder block. 8. Loosen the bolts Tool (B) that hold camshaft rear gear (5) so camshaft rear gear (5) will engage the dowel on the rear of the camshaft.9. After the dowel is engaged, remove Tool (B), and install bolts (4).10. Use Tool (A) to turn the flywheel, and install each of four bolts (4). Tighten bolts (4) to a torque of 23 to 31 N m (17 to 23 lb ft).11. Put 5P-3413 Pipe Sealant with "Teflon" on the

Tooling (C) must be used to prevent the loss of rear balance weight timing and to keep the camshaft rear gear in place when the camshaft is removed.

9. Tighten Tooling (C) evenly to remove the camshaft rear gear from the camshaft. 10. Remove thrust plate (8).

Be careful not to damage the camshaft bearings. Do not pry the camshaft out of the cylinder block. If resistance to camshaft removal occurs, turn the camshaft so the lobes will align the bearing journals with the camshaft bearing bores.

11. Carefully remove the camshaft and gear (9) from the cylinder block.12. If removal of the camshaft gear is necessary, place the camshaft and gear in a hydraulic press. Place Tool (D) over the camshaft, and press against it to remove the camshaft from the gear.

Be careful not to scratch or mar the finished surfaces of the camshaft.

13. Remove the key from the camshaft.14. If dowel removal is necessary, use Tool (E) to remove the dowel.Install Camshaft

1. Install the key in the camshaft. Be sure the key is seated in the camshaft.2. Install the pin in the rear of the camshaft. Install the pin to a height of 8.51 to 9.01 mm (.335 to .355 in).3. Heat the camshaft drive gear to a maximum temperature of 204° C (400° F), align the groove in the drive gear with the key in the camshaft, and install the camshaft drive gear with the timing marks away from the camshaft.4. Put clean engine oil on the camshaft bearing journals and lobes.5. Carefully install the camshaft into the cylinder block. Do not force the camshaft into position. If resistance to camshaft installation occurs, turn the camshaft so the lobes will align the bearing journals with the camshaft bearing bores. 6. Align the "V" marks on camshaft drive gear (2) and idler gear (3).7. Install thrust plate (1) to hold the camshaft and camshaft drive gear (2) in the cylinder block. 8. Loosen the bolts Tool (B) that hold camshaft rear gear (5) so camshaft rear gear (5) will engage the dowel on the rear of the camshaft.9. After the dowel is engaged, remove Tool (B), and install bolts (4).10. Use Tool (A) to turn the flywheel, and install each of four bolts (4). Tighten bolts (4) to a torque of 23 to 31 N m (17 to 23 lb ft).11. Put 5P-3413 Pipe Sealant with "Teflon" on the

Have questions with 106673-7110?

Group cross 106673-7110 ZEXEL

Mitsubishi

106673-7110

9 400 617 325

ME151383

INJECTION-PUMP ASSEMBLY

6D22T3

6D22T3