Information injection-pump assembly

BOSCH

9 400 619 420

9400619420

ZEXEL

106673-3390

1066733390

HINO

220206480A

220206480a

Rating:

Service parts 106673-3390 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

14.

NOZZLE

Include in #1:

106673-3390

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 619 420

9400619420

ZEXEL

106673-3390

1066733390

HINO

220206480A

220206480a

Zexel num

Bosch num

Firm num

Name

106673-3390

9 400 619 420

220206480A HINO

INJECTION-PUMP ASSEMBLY

K13C-TI K 14CA INJECTION PUMP ASSY PE6P,6PD PE

K13C-TI K 14CA INJECTION PUMP ASSY PE6P,6PD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-3420

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.9

3.84

3.9

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.75 60.25

Cal 1-4 deg. 60 59.75 60.25

Difference between angles 2

Cyl.1-2 deg. 120 119.75 120.25

Cyl.1-2 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cal 1-3 deg. 240 239.75 240.25

Cal 1-3 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-5 deg. 300 299.75 300.25

Cal 1-5 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

A

Rack position

12.2

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

187

185

189

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Boost pressure

kPa

57.3

57.3

Boost pressure

mmHg

430

430

Injection quantity adjustment_02

Adjusting point

-

Rack position

7.2+-0.5

Pump speed

r/min

360

360

360

Average injection quantity

mm3/st.

14.8

11.8

17.8

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Boost compensator adjustment

Pump speed

r/min

600

600

600

Rack position

10.95

Boost pressure

kPa

3.3

3.3

5.3

Boost pressure

mmHg

25

25

40

Boost compensator adjustment_02

Pump speed

r/min

600

600

600

Rack position

(13.2)

Boost pressure

kPa

44

44

44

Boost pressure

mmHg

330

330

330

Timer adjustment

Pump speed

r/min

750--

Advance angle

deg.

0

0

0

Load

3/4

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

700

Advance angle

deg.

0.3

Load

3/4

Timer adjustment_03

Pump speed

r/min

1000

Advance angle

deg.

3.5

3.2

3.8

Load

4/4

Remarks

Finish

Finish

Test data Ex:

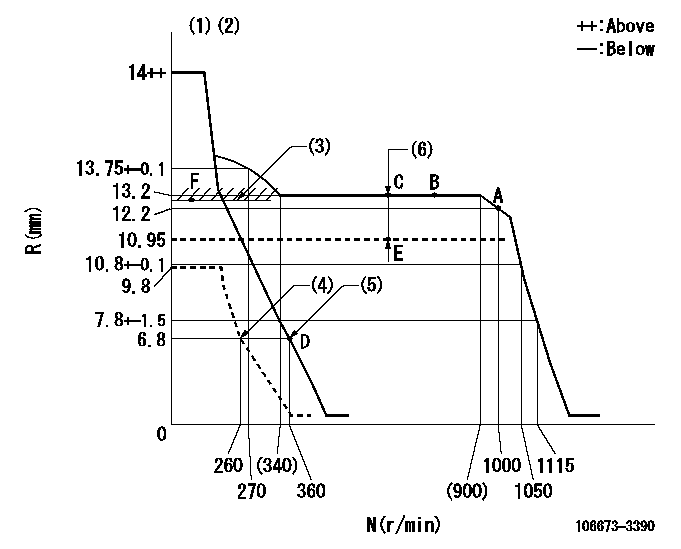

Governor adjustment

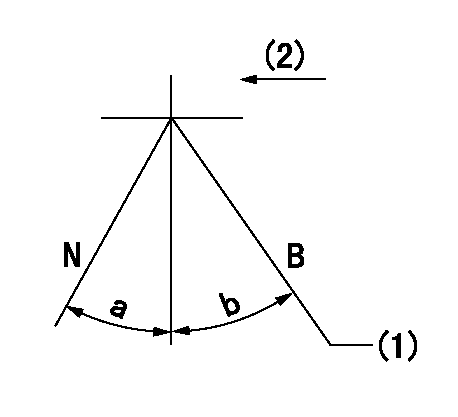

N:Pump speed

R:Rack position (mm)

(1)Notch fixed: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Boost compensator excessive fuel lever at operation: L1 (at 0 boost pressure)

(4)Set idle sub-spring

(5)Main spring setting

(6)Boost compensator stroke: BCL

----------

K=13 L1=13.1+-0.1mm BCL=(2.25)mm

----------

----------

K=13 L1=13.1+-0.1mm BCL=(2.25)mm

----------

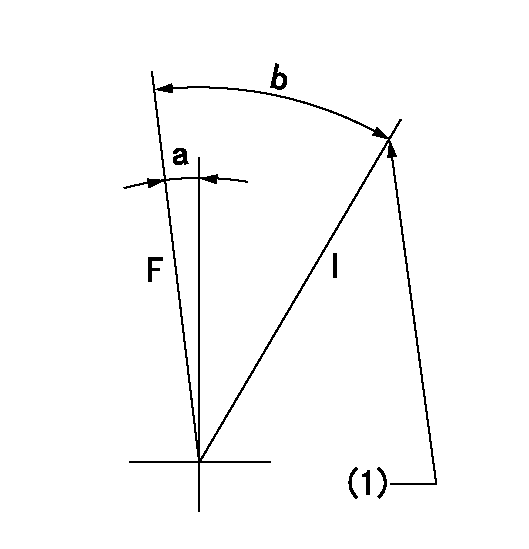

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=(7deg)+-5deg b=(23deg)+-5deg

----------

----------

a=(7deg)+-5deg b=(23deg)+-5deg

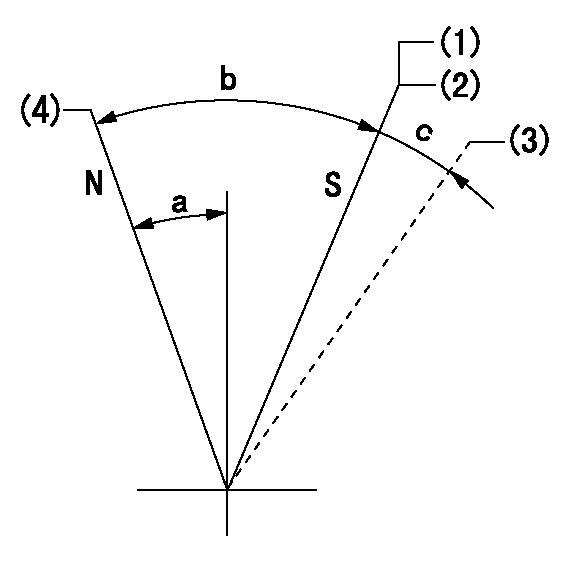

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Contacts inner boss.

(2)Rack position aa or less, pump speed bb

(3)Contacts outer boss.

(4)Normal

----------

aa=6.3mm bb=0r/min

----------

a=27deg+-5deg b=53deg+-5deg c=(11deg)

----------

aa=6.3mm bb=0r/min

----------

a=27deg+-5deg b=53deg+-5deg c=(11deg)

0000001101

N:Normal

B:When boosted

(1)Rack position = aa (at point F) at boost pressure = 0

(2)Drive side

----------

aa=13.1+-0.1mm

----------

a=(15deg) b=(8deg)

----------

aa=13.1+-0.1mm

----------

a=(15deg) b=(8deg)

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(1deg)

----------

----------

a=(1deg)

Information:

Overheating1. Defective Temperature Gauge If the temperature gauge shows that the coolant temperature is above normal and all other conditions indicate that conditions are normal, check the coolant temperature in another method, such as: * Read the coolant temperature with an ECAP or DDT.* Install an 8T0470 Thermistor Thermometer Group* Install a temperature sensitive tape.* Install a new gauge that is known to be good.2. Low Coolant Level Low coolant level can cause overheating to occur. Low coolant level can be caused by leaks in the cooling system or by improper filling of the radiator. With the engine cool, the coolant level should be at the low end of the fill neck on the radiator. If the coolant is below this level, a visual inspection should be done to see if any leaks can be seen. If nothing obvious is seen, refer to the topic Loss Of Coolant in this section. Fill the radiator according to recommendations in the Operation & Maintenance Manual.3. Dirty Radiator Check for debris between the fins of the radiator core which could restrict the free flow of air through the radiator core. Also check for debris or deposits on the inside of the core which could restrict the free flow of coolant through the radiator. Clean out any debris that is found.4. Fan Belt Slippage Check for proper fan speed with the fan engaged. Check the belt tension. Check the belt tensioner bearing and spring for proper operation. Check the belt and pulleys for lubricant contaminants which could cause belt slippage. Check the belt for hardening and glaze caused by heat and slippage. Repair or replace any defective parts that are detected.5. Defective Hoses Check the hoses for leaks, cuts and loose clamps. Check for any hoses that are collapsed or restricted that could cause a decrease in the amount of flow of coolant through the engine or radiator. Replace as necessary.6. Defective Pressure Cap Inspect the sealing surface of the pressure cap and the radiator. Look for any damage to the seal or the sealing surface. Remove any foreign material and replace any defective seals. Check the sealing pressure of the cap with the Cooling System Pressurization Pump Group, 9S8140. This will check the opening pressure of the cap. If the cap is defective, replace it.7. Defective Water Temperature Regulator If the water temperature regulator is not opening properly or if the seal is damaged, it can cause the engine to overheat. Check the water temperature regulator for proper operation according to the test procedure for the thermostat located in the Testing and Adjusting section of Systems Operation, Testing and Adjusting, Form No. SENR4964.8. Defective Water Pump Check the water pump impeller for damage or looseness on the shaft. Also, see the topic, Cooling System, in the Testing and Adjusting section of Systems Operation, Testing and Adjusting, Form No. SENR4964.9. Air/Combustion Gas In The Cooling System Air/Combustion Gas in the cooling system reduces the heat transfer from hot engine parts to

Have questions with 106673-3390?

Group cross 106673-3390 ZEXEL

Hino

Hino

106673-3390

9 400 619 420

220206480A

INJECTION-PUMP ASSEMBLY

K13C-TI

K13C-TI