Information injection-pump assembly

BOSCH

9 400 617 304

9400617304

ZEXEL

106673-3350

1066733350

HINO

220206140A

220206140a

Rating:

Cross reference number

BOSCH

9 400 617 304

9400617304

ZEXEL

106673-3350

1066733350

HINO

220206140A

220206140a

Zexel num

Bosch num

Firm num

Name

106673-3350

9 400 617 304

220206140A HINO

INJECTION-PUMP ASSEMBLY

K13C-T K

K13C-T K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

134424-0920

Overflow valve opening pressure

kPa

162

147

177

Overflow valve opening pressure

kgf/cm2

1.65

1.5

1.8

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.9

3.84

3.9

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.75 60.25

Cal 1-4 deg. 60 59.75 60.25

Difference between angles 2

Cyl.1-2 deg. 120 119.75 120.25

Cyl.1-2 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cal 1-3 deg. 240 239.75 240.25

Cal 1-3 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-5 deg. 300 299.75 300.25

Cal 1-5 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

A

Rack position

10.8

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

188

186

190

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Boost pressure

kPa

38

38

Boost pressure

mmHg

285

285

Injection quantity adjustment_02

Adjusting point

C

Rack position

5.2+-0.5

Pump speed

r/min

360

360

360

Average injection quantity

mm3/st.

9

6

12

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_03

Adjusting point

D

Rack position

11++

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

165

165

175

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Rack limit

*

Boost compensator adjustment

Pump speed

r/min

600

600

600

Rack position

R2(R1-2.

2)

Boost pressure

kPa

4

4

4

Boost pressure

mmHg

30

30

30

Boost compensator adjustment_02

Pump speed

r/min

600

600

600

Rack position

R2+0.9

Boost pressure

kPa

11.3

8.6

14

Boost pressure

mmHg

85

65

105

Boost compensator adjustment_03

Pump speed

r/min

600

600

600

Rack position

R1(10.8)

Boost pressure

kPa

24.7

24.7

24.7

Boost pressure

mmHg

185

185

185

Timer adjustment

Pump speed

r/min

(N1+50)-

-

Advance angle

deg.

0

0

0

Load

3/4

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

N1

Advance angle

deg.

0.3

Load

3/4

Remarks

Measure the actual speed.

Measure the actual speed.

Timer adjustment_03

Pump speed

r/min

900

Load

4/4

Remarks

Measure the actual advance angle.

Measure the actual advance angle.

Timer adjustment_04

Pump speed

r/min

-

Advance angle

deg.

3

2.7

3.3

Load

4/4

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

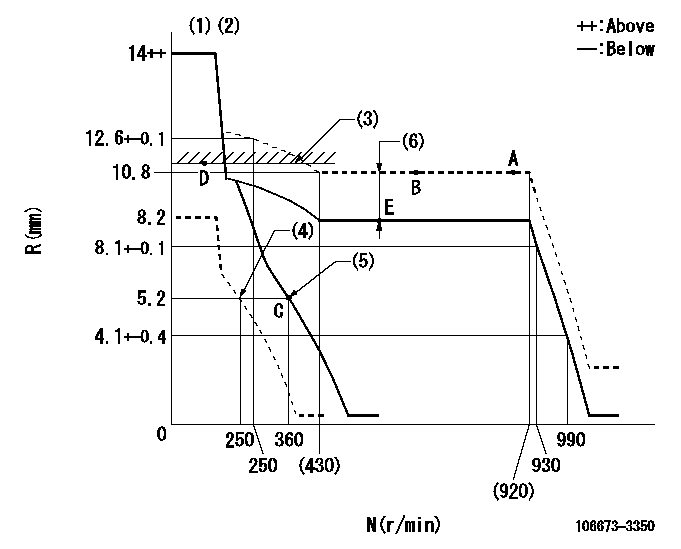

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Set idle sub-spring

(5)Main spring setting

(6)Boost compensator stroke: BCL

----------

K=12 BCL=2.2+-0.1mm

----------

----------

K=12 BCL=2.2+-0.1mm

----------

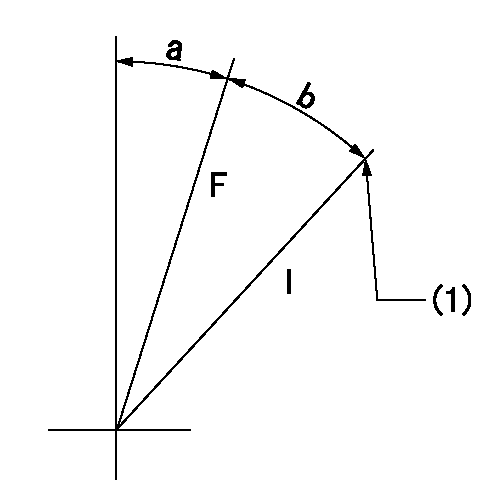

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=0deg+-5deg b=18deg+-5deg

----------

----------

a=0deg+-5deg b=18deg+-5deg

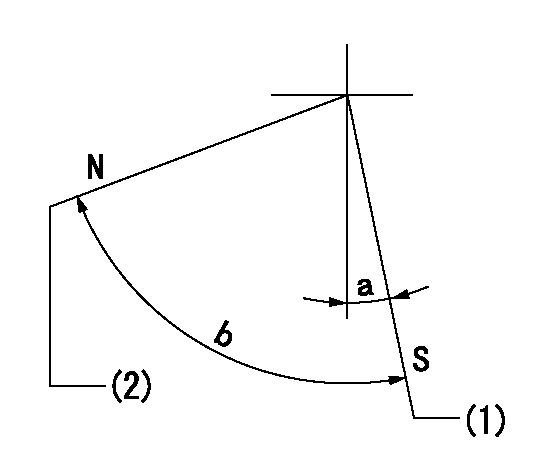

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Pump speed aa and rack position bb (to be sealed at delivery)

(2)Normal

----------

aa=0r/min bb=1-0.5mm

----------

a=10deg+-5deg b=70deg+-5deg

----------

aa=0r/min bb=1-0.5mm

----------

a=10deg+-5deg b=70deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(0deg)

----------

----------

a=(0deg)

Information:

Diagnostic Code 35 Engine Overspeed Warning

Conditions Which Generate This Code:The Electronic Control Module (ECM) detects an engine speed greater than 3300 rpm. System Response:1. Diagnostic Code 35 is current (Diagnostic Lamp, ECAP, or DDT) and is LOGGED in memory. -AND-2. The 3176 System will attempt to limit engine rpm to Top Engine Limit (TEL) by not allowing the unit injectors to inject fuel. The injectors are shut off because the engine is running at a speed that exceeds rated rpm. A diagnostic code 35 has no effect on performance. Troubleshooting:Diagnostic Code 35 warns of an overspeed condition and is for information only. It does not indicate a fault in the 3176 System.Factory passwords are required to clear a diagnostic code 35.Diagnostic Code 37 Fuel Pressure Sensor Fault

Conditions Which Generate This Code:Fuel Pressure Sensor signal voltage drops below 0.2 volts DC or rises above 4.7 volts DC for at least ten seconds. System Response:1. Diagnostic Code 37 is current (Diagnostic Lamp, ECAP, or DDT) and is LOGGED in memory.2. Electronic Control Module (ECM) "Fuel Pressure" reading is set to 0 kPa (0 psi) when fault is active.3. Engine operation is NOT affected. Troubleshooting:Follow P-226: Fuel Pressure Sensor Test, in this manualDiagnostic Code 42 Check Sensor Calibrations

On new (replacement) Electronic Control Modules (ECM), Diagnostic Code 42 will appear until sensors have been calibrated. Conditions Which Generate This Code:1. The Speed/Timing Sensor is not correctly calibrated, -AND/OR-2. The Boost Pressure Sensor is not correctly calibrated. System Response:1. Diagnostic Code 42 is current (Diagnostic Lamp, ECAP, or DDT) but is NOT LOGGED in memory.2. If Speed/Timing Sensor is not correctly calibrated, injection timing will default to base timing.3. If Boost Pressure Sensor is not correctly calibrated, then boost pressure is set to 0 kPa (0 psi) by the ECM. This will limit fuel delivery rate which in turn will limit engine horsepower. Troubleshooting:1. Use an ECAP or DDT to calibrate the Boost Pressure Sensor. Follow P-302: Boost Pressure Sensor Calibration, in this manual.2. Only an ECAP can be used to calibrate the Speed/Timing Sensor. Follow P-301: Speed/Timing Sensor Calibration, in this manual or "Calibrating Injection Timing" in the 3176 Vehicular Diesel Engine, Systems Operation Testing And Adjusting Manual, Form SENR4964.Diagnostic Code 51 Intermittent Battery Power To ECM

Conditions Which Generate This Code:Battery voltage to the Electronic Control Module (ECM) momentarily drops below six volts DC. Quickly turning the key off, then back on, may cause a Code 51 to be generated. System Response:1. Diagnostic Code 51 is current (Diagnostic Lamp, ECAP, or DDT) and remains active as long as the key is ON. Fault is LOGGED in memory only if the fault occurs while the engine is running.2. Interruption of electrical power may result in a brief loss of engine power or a complete engine shutdown, depending on the duration of the electrical power loss. Troubleshooting:Follow P-210: Electrical Power Supply Test, in this manual.Diagnostic Code 52 ECM or Personality Module Fault

Conditions Which Generate This Code:The Electronic Control Module (ECM) has detected a fault

Conditions Which Generate This Code:The Electronic Control Module (ECM) detects an engine speed greater than 3300 rpm. System Response:1. Diagnostic Code 35 is current (Diagnostic Lamp, ECAP, or DDT) and is LOGGED in memory. -AND-2. The 3176 System will attempt to limit engine rpm to Top Engine Limit (TEL) by not allowing the unit injectors to inject fuel. The injectors are shut off because the engine is running at a speed that exceeds rated rpm. A diagnostic code 35 has no effect on performance. Troubleshooting:Diagnostic Code 35 warns of an overspeed condition and is for information only. It does not indicate a fault in the 3176 System.Factory passwords are required to clear a diagnostic code 35.Diagnostic Code 37 Fuel Pressure Sensor Fault

Conditions Which Generate This Code:Fuel Pressure Sensor signal voltage drops below 0.2 volts DC or rises above 4.7 volts DC for at least ten seconds. System Response:1. Diagnostic Code 37 is current (Diagnostic Lamp, ECAP, or DDT) and is LOGGED in memory.2. Electronic Control Module (ECM) "Fuel Pressure" reading is set to 0 kPa (0 psi) when fault is active.3. Engine operation is NOT affected. Troubleshooting:Follow P-226: Fuel Pressure Sensor Test, in this manualDiagnostic Code 42 Check Sensor Calibrations

On new (replacement) Electronic Control Modules (ECM), Diagnostic Code 42 will appear until sensors have been calibrated. Conditions Which Generate This Code:1. The Speed/Timing Sensor is not correctly calibrated, -AND/OR-2. The Boost Pressure Sensor is not correctly calibrated. System Response:1. Diagnostic Code 42 is current (Diagnostic Lamp, ECAP, or DDT) but is NOT LOGGED in memory.2. If Speed/Timing Sensor is not correctly calibrated, injection timing will default to base timing.3. If Boost Pressure Sensor is not correctly calibrated, then boost pressure is set to 0 kPa (0 psi) by the ECM. This will limit fuel delivery rate which in turn will limit engine horsepower. Troubleshooting:1. Use an ECAP or DDT to calibrate the Boost Pressure Sensor. Follow P-302: Boost Pressure Sensor Calibration, in this manual.2. Only an ECAP can be used to calibrate the Speed/Timing Sensor. Follow P-301: Speed/Timing Sensor Calibration, in this manual or "Calibrating Injection Timing" in the 3176 Vehicular Diesel Engine, Systems Operation Testing And Adjusting Manual, Form SENR4964.Diagnostic Code 51 Intermittent Battery Power To ECM

Conditions Which Generate This Code:Battery voltage to the Electronic Control Module (ECM) momentarily drops below six volts DC. Quickly turning the key off, then back on, may cause a Code 51 to be generated. System Response:1. Diagnostic Code 51 is current (Diagnostic Lamp, ECAP, or DDT) and remains active as long as the key is ON. Fault is LOGGED in memory only if the fault occurs while the engine is running.2. Interruption of electrical power may result in a brief loss of engine power or a complete engine shutdown, depending on the duration of the electrical power loss. Troubleshooting:Follow P-210: Electrical Power Supply Test, in this manual.Diagnostic Code 52 ECM or Personality Module Fault

Conditions Which Generate This Code:The Electronic Control Module (ECM) has detected a fault

Have questions with 106673-3350?

Group cross 106673-3350 ZEXEL

Hino

Hino

106673-3350

9 400 617 304

220206140A

INJECTION-PUMP ASSEMBLY

K13C-T

K13C-T