Information injection-pump assembly

BOSCH

9 400 617 303

9400617303

ZEXEL

106673-3341

1066733341

HINO

220206121A

220206121a

Rating:

Cross reference number

BOSCH

9 400 617 303

9400617303

ZEXEL

106673-3341

1066733341

HINO

220206121A

220206121a

Zexel num

Bosch num

Firm num

Name

9 400 617 303

220206121A HINO

INJECTION-PUMP ASSEMBLY

P09C-T * K 14CA PE6P,6PD PE

P09C-T * K 14CA PE6P,6PD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

134424-1420

Overflow valve opening pressure

kPa

162

147

177

Overflow valve opening pressure

kgf/cm2

1.65

1.5

1.8

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.9

3.8

3.9

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

11.3

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

151.5

149.5

153.5

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Boost pressure

kPa

52

52

Boost pressure

mmHg

390

390

Injection quantity adjustment_02

Adjusting point

C

Rack position

6.5+-0.5

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

10

7

13

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_03

Adjusting point

E

Rack position

11.5++

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

135

130

140

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Rack limit

*

Boost compensator adjustment

Pump speed

r/min

600

600

600

Rack position

R1-1.95

Boost pressure

kPa

4

4

6

Boost pressure

mmHg

30

30

45

Boost compensator adjustment_02

Pump speed

r/min

600

600

600

Rack position

R1(11.3)

Boost pressure

kPa

38.7

38.7

38.7

Boost pressure

mmHg

290

290

290

Timer adjustment

Pump speed

r/min

(N1+50)-

-

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

N1

Advance angle

deg.

0.3

Remarks

Measure the actual speed.

Measure the actual speed.

Timer adjustment_03

Pump speed

r/min

-

Advance angle

deg.

1.5

1.2

1.8

Remarks

Measure the actual speed.

Measure the actual speed.

Timer adjustment_04

Pump speed

r/min

(1100)

Advance angle

deg.

2

1.5

2.5

Remarks

Finish

Finish

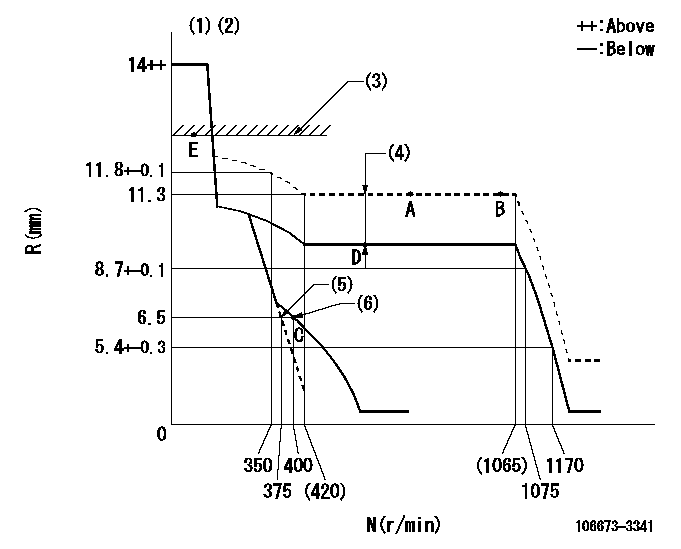

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Boost compensator stroke: BCL

(5)Main spring setting

(6)Set idle sub-spring

----------

K=14 BCL=1.95+-0.1mm

----------

----------

K=14 BCL=1.95+-0.1mm

----------

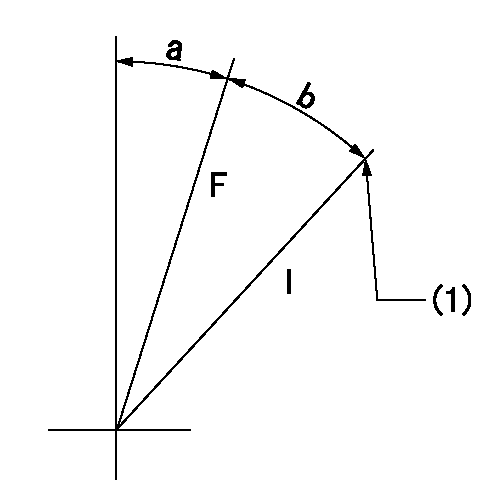

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=3deg+-5deg b=13deg+-5deg

----------

----------

a=3deg+-5deg b=13deg+-5deg

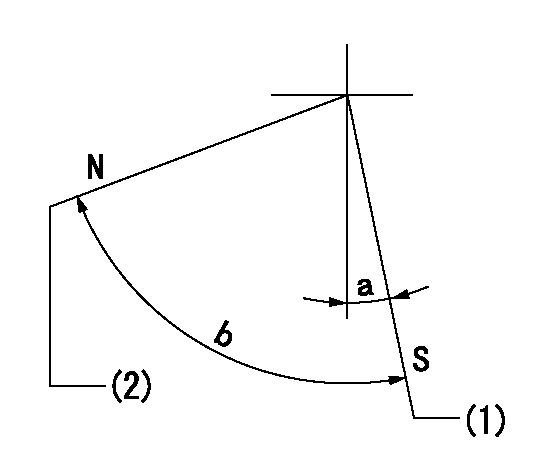

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Pump speed aa and rack position bb (to be sealed at delivery)

(2)Normal

----------

aa=0r/min bb=1-0.5mm

----------

a=10deg+-5deg b=70deg+-5deg

----------

aa=0r/min bb=1-0.5mm

----------

a=10deg+-5deg b=70deg+-5deg

0000001501 TAMPER PROOF

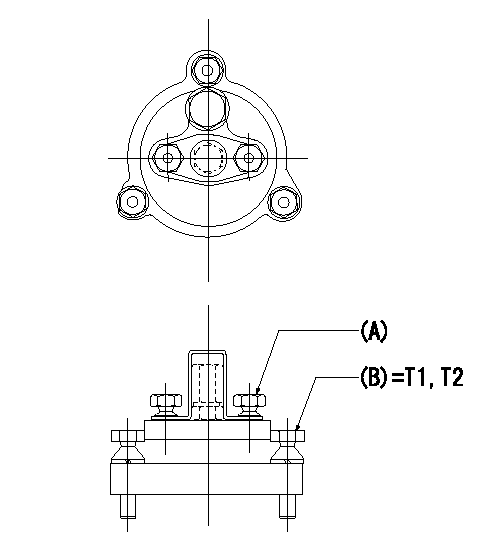

Tamperproofing-equipped boost compensator cover installation procedure

(A): After adjusting the boost compensator, assemble then tighten the bolts to remove the heads.

(B): Specified torque

(1)Before adjusting the governor and the boost compensator, tighten the screw to the specified torque.

(Tightening torque T = T1 maximum)

(2)After adjusting the governor and the boost compensator, tighten to the specified torque to break off the bolt heads.

(Tightening torque T = T2)

----------

T1=2.5N-m(0.25kgf-m) T2=2.9~4.4N-m(0.3~0.45kgf-m)

----------

----------

T1=2.5N-m(0.25kgf-m) T2=2.9~4.4N-m(0.3~0.45kgf-m)

----------

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(50deg)

----------

----------

a=(50deg)

Information:

3176 Electronic Governor Fuel Injection

The ECM controls the amount of fuel injected, by varying signals to the injectors. The injectors will inject fuel ONLY if the injector solenoid is energized. The ECM sends a 100 volt signal to the solenoid to energize it. By controlling the timing and duration of the 100 volt signal, the ECM can control injection timing and the amount of fuel injected.The ECM sets certain limits on the amount of fuel that can be injected. "FRC Fuel Pos" is a limit based on boost pressure to control the fuel-air ratio, for emissions control purposes. When the ECM senses a higher boost pressure (more air into cylinder), it increases the "FRC Fuel Pos" limit (allows more fuel into cylinder). "Rated Fuel Pos" is a limit based on the horsepower rating of the engine. It is similar to the rack stops and torque spring on a mechanically-governed engine. It provides horsepower and torque curves for a specific engine family and rating. All of these limits are programmed by the factory into the Personality Module and are not programmable in the field.Injection timing depends on engine rpm, load and other operation factors. The ECM knows where top-dead-center of cylinder number one is from the signal provided by the engine Speed/Timing Sensor. It decides when injection should occur relative to top-dead-center and provides the signal to the injector at the desired time.Under certain conditions, the 3176 Engine may intentionally operate on just three cylinders. This feature is called "Three Cylinder Cutout" and occurs when the engine is operated under no load, at high rpm (when signals to the injectors are of very short duration). Under these conditions, the ECM does not inject fuel into cylinders 4, 5 and 6. This allows for more precise fuel metering to cylinders 1, 2 and 3. The accompanying change in feel and sound of the engine should not be misdiagnosed as an engine problem. When more power is needed, all six cylinders will be fueled and full power delivered.Programmable Parameters

Certain parameters that affect 3176 Vehicular Diesel Engine operation may be changed through electronic service tools (either the ECAP or DDT). The parameters are stored in the ECM and passwords are used to prevent unauthorized changes.Password protected parameters are either "System Configuration Parameters" or "Customer Specified Parameters". System Configuration Parameters are set at the factory and affect emissions or horsepower ratings within a family of engines. Factory passwords must be obtained and used to change System Configuration Parameters. Customer Specified Parameters are variable and can be used to affect such things as the rpm/horsepower ratings within the limits set by the factory. Customer Passwords must be used to change Customer Specified Parameters.If the operator has not had adequate training, some parameters may affect engine operation in ways that are not expected. This may lead to power or performance complaints, even though the engine is operating correctly.Passwords

"System Configuration Parameters" are protected by factory passwords. System Configuration Parameters are those that affect horsepower family or

The ECM controls the amount of fuel injected, by varying signals to the injectors. The injectors will inject fuel ONLY if the injector solenoid is energized. The ECM sends a 100 volt signal to the solenoid to energize it. By controlling the timing and duration of the 100 volt signal, the ECM can control injection timing and the amount of fuel injected.The ECM sets certain limits on the amount of fuel that can be injected. "FRC Fuel Pos" is a limit based on boost pressure to control the fuel-air ratio, for emissions control purposes. When the ECM senses a higher boost pressure (more air into cylinder), it increases the "FRC Fuel Pos" limit (allows more fuel into cylinder). "Rated Fuel Pos" is a limit based on the horsepower rating of the engine. It is similar to the rack stops and torque spring on a mechanically-governed engine. It provides horsepower and torque curves for a specific engine family and rating. All of these limits are programmed by the factory into the Personality Module and are not programmable in the field.Injection timing depends on engine rpm, load and other operation factors. The ECM knows where top-dead-center of cylinder number one is from the signal provided by the engine Speed/Timing Sensor. It decides when injection should occur relative to top-dead-center and provides the signal to the injector at the desired time.Under certain conditions, the 3176 Engine may intentionally operate on just three cylinders. This feature is called "Three Cylinder Cutout" and occurs when the engine is operated under no load, at high rpm (when signals to the injectors are of very short duration). Under these conditions, the ECM does not inject fuel into cylinders 4, 5 and 6. This allows for more precise fuel metering to cylinders 1, 2 and 3. The accompanying change in feel and sound of the engine should not be misdiagnosed as an engine problem. When more power is needed, all six cylinders will be fueled and full power delivered.Programmable Parameters

Certain parameters that affect 3176 Vehicular Diesel Engine operation may be changed through electronic service tools (either the ECAP or DDT). The parameters are stored in the ECM and passwords are used to prevent unauthorized changes.Password protected parameters are either "System Configuration Parameters" or "Customer Specified Parameters". System Configuration Parameters are set at the factory and affect emissions or horsepower ratings within a family of engines. Factory passwords must be obtained and used to change System Configuration Parameters. Customer Specified Parameters are variable and can be used to affect such things as the rpm/horsepower ratings within the limits set by the factory. Customer Passwords must be used to change Customer Specified Parameters.If the operator has not had adequate training, some parameters may affect engine operation in ways that are not expected. This may lead to power or performance complaints, even though the engine is operating correctly.Passwords

"System Configuration Parameters" are protected by factory passwords. System Configuration Parameters are those that affect horsepower family or