Information injection-pump assembly

ZEXEL

106673-2870

1066732870

Rating:

Cross reference number

ZEXEL

106673-2870

1066732870

Zexel num

Bosch num

Firm num

Name

106673-2870

INJECTION-PUMP ASSEMBLY

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-4620

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.8

4.75

4.85

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

11.8

Pump speed

r/min

850

850

850

Average injection quantity

mm3/st.

133

130

136

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Boost pressure

kPa

62.7

62.7

Boost pressure

mmHg

470

470

Injection quantity adjustment_02

Adjusting point

B

Rack position

6.1+-0.5

Pump speed

r/min

275

275

275

Average injection quantity

mm3/st.

13.8

11.2

16.4

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_03

Adjusting point

E

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

121

101

141

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Rack limit

*

Boost compensator adjustment

Pump speed

r/min

600

600

600

Rack position

(10.7)

Boost pressure

kPa

13.3

12

14.6

Boost pressure

mmHg

100

90

110

Boost compensator adjustment_02

Pump speed

r/min

600

600

600

Rack position

12.1

Boost pressure

kPa

49.3

42.6

56

Boost pressure

mmHg

370

320

420

Timer adjustment

Pump speed

r/min

950--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

900

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1100

Advance angle

deg.

1

0.5

1.5

Remarks

Finish

Finish

Test data Ex:

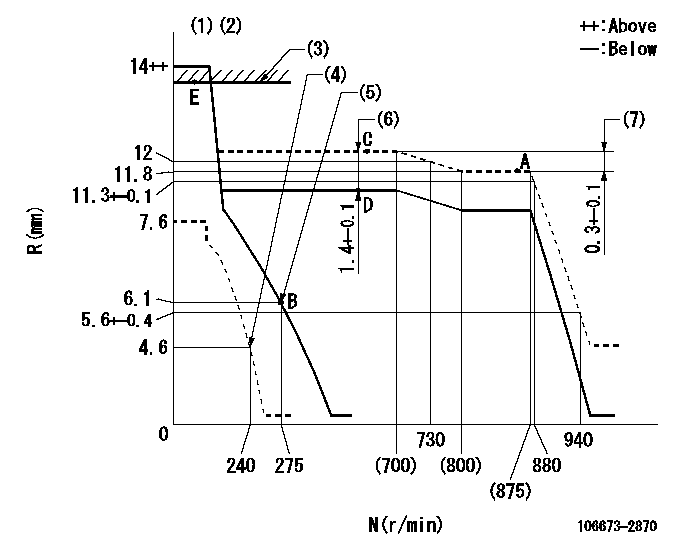

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Set idle sub-spring

(5)Main spring setting

(6)Boost compensator stroke

(7)Rack difference between N = N1 and N = N2

----------

K=9 N1=850r/min N2=625r/min

----------

----------

K=9 N1=850r/min N2=625r/min

----------

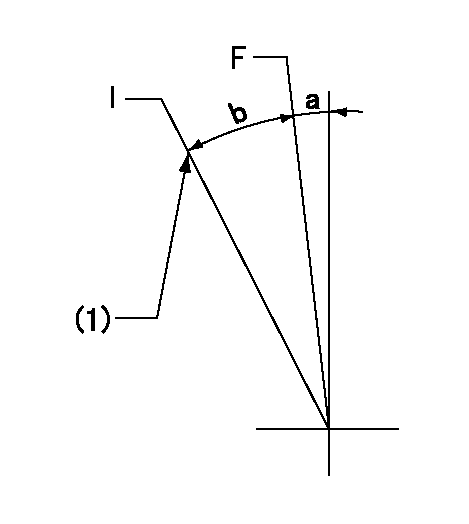

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=3deg+-5deg b=24deg+-5deg

----------

----------

a=3deg+-5deg b=24deg+-5deg

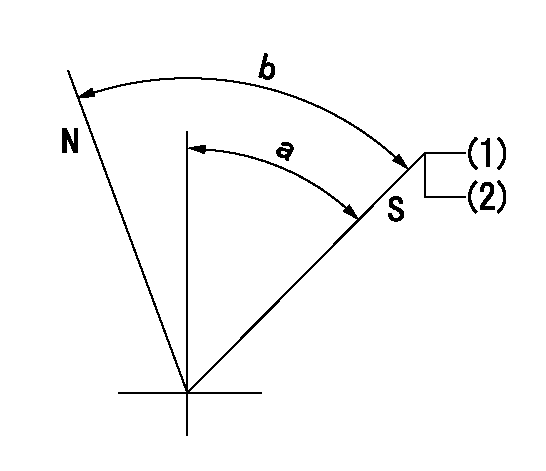

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Pump speed aa and rack position bb (to be sealed at delivery)

(2)Stopper bolt setting

----------

aa=0r/min bb=1-0.2mm

----------

a=35deg+-5deg b=70deg+-5deg

----------

aa=0r/min bb=1-0.2mm

----------

a=35deg+-5deg b=70deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(7deg)

----------

----------

a=(7deg)

Information:

789 Truck

On the 789 Truck, there are two mounting plates and two sets of ether nozzles, both of which are mounted on the frame cross tube in the engine compartment. 1. Install 8X0913 Tube (63) in the front nozzle, and 8W8177 Tube (65) in the rear nozzle of the front pair of turbocharger outlet adapters as shown.2. Use two 5P6314 Sleeves with 5P6313 Nuts to connect tubes (63) and (65) to 8C9006 Tee (64).3. Put 8X5015 Tube (60) in position along the cylinder block and frame cross tube (59). Use a 5P6314 Sleeve and a 5P6313 Nut to connect tube (60) to 8C9006 Tee (64) as shown.4. Connect one end of a 7N0140 Tube Assembly in the bottom of the shuttle valve on the right side mounting plate (62) to the free end of 8X5015 Tube (60).5. Use three 6V2686 Clips (61), with existing bolts on the engine cylinder block and truck frame cross tube (59), to secure 8X5015 Tube (60) as shown.6. Install 8W8179 Tube (66) in the front nozzle and 8W8180 Tube (67) in the rear nozzle of the rear pair of turbocharger outlet adapters as shown.7. Use two 5P6314 Sleeves with 5P6313 Nuts to connect tubes (66) and (67) to 8C9006 Tee (68).8. Use two 6V2686 Clips (61) with existing bolts to secure 8W8180 Tube (67) to the engine block as shown.9. Put 8W8178 Tube (69) in position along the cylinder block and connect it to 8C9006 Tee (68) as shown using a 5P6314 Sleeve and 5P6313 Nut.10. Connect one end of a 7N0140 Tube Assembly in the bottom connector of the shuttle valve on left side mounting plate (70) to the free end of the 8W8178 Tube (69).11. Use three 6V2686 Clips (61) with existing bolts on engine cylinder block to secure 8W8178 Tube (69) as shown.Installation of Ether Cylinders

1. Turn the disconnect switch to the ON position and put the start switch key in the OFF position. Make sure the two lamps on the console and the two yellow LEDs on the ECU are flashing.If they are flashing, it indicates that the control is functioning and recognizes that no ether cylinders are installed.2. Inspect the two digit, seven segment LED display on the ECU. It must read "00". This in an indication that there are no faults.If the display does not read "00", refer to the Service Manual, SENR4705, for a troubleshooting procedure of the system. 3. Remove protective caps (71) and (72) from 9X7137 Ether Solenoid Valves (73) and (74) (left side ether assembly mounting plate on 789 Truck when viewed from the rear of the engine). Install a new 9X7138 Filter Assembly in each solenoid valve inlet if one is not already in place.4. Install a 9X0147 Collar on the neck of each new 7X1062 Ether Cylinder.5. Remove the protective plug from the end of the new FULL ether cylinder, then install the new ether cylinder for ether

On the 789 Truck, there are two mounting plates and two sets of ether nozzles, both of which are mounted on the frame cross tube in the engine compartment. 1. Install 8X0913 Tube (63) in the front nozzle, and 8W8177 Tube (65) in the rear nozzle of the front pair of turbocharger outlet adapters as shown.2. Use two 5P6314 Sleeves with 5P6313 Nuts to connect tubes (63) and (65) to 8C9006 Tee (64).3. Put 8X5015 Tube (60) in position along the cylinder block and frame cross tube (59). Use a 5P6314 Sleeve and a 5P6313 Nut to connect tube (60) to 8C9006 Tee (64) as shown.4. Connect one end of a 7N0140 Tube Assembly in the bottom of the shuttle valve on the right side mounting plate (62) to the free end of 8X5015 Tube (60).5. Use three 6V2686 Clips (61), with existing bolts on the engine cylinder block and truck frame cross tube (59), to secure 8X5015 Tube (60) as shown.6. Install 8W8179 Tube (66) in the front nozzle and 8W8180 Tube (67) in the rear nozzle of the rear pair of turbocharger outlet adapters as shown.7. Use two 5P6314 Sleeves with 5P6313 Nuts to connect tubes (66) and (67) to 8C9006 Tee (68).8. Use two 6V2686 Clips (61) with existing bolts to secure 8W8180 Tube (67) to the engine block as shown.9. Put 8W8178 Tube (69) in position along the cylinder block and connect it to 8C9006 Tee (68) as shown using a 5P6314 Sleeve and 5P6313 Nut.10. Connect one end of a 7N0140 Tube Assembly in the bottom connector of the shuttle valve on left side mounting plate (70) to the free end of the 8W8178 Tube (69).11. Use three 6V2686 Clips (61) with existing bolts on engine cylinder block to secure 8W8178 Tube (69) as shown.Installation of Ether Cylinders

1. Turn the disconnect switch to the ON position and put the start switch key in the OFF position. Make sure the two lamps on the console and the two yellow LEDs on the ECU are flashing.If they are flashing, it indicates that the control is functioning and recognizes that no ether cylinders are installed.2. Inspect the two digit, seven segment LED display on the ECU. It must read "00". This in an indication that there are no faults.If the display does not read "00", refer to the Service Manual, SENR4705, for a troubleshooting procedure of the system. 3. Remove protective caps (71) and (72) from 9X7137 Ether Solenoid Valves (73) and (74) (left side ether assembly mounting plate on 789 Truck when viewed from the rear of the engine). Install a new 9X7138 Filter Assembly in each solenoid valve inlet if one is not already in place.4. Install a 9X0147 Collar on the neck of each new 7X1062 Ether Cylinder.5. Remove the protective plug from the end of the new FULL ether cylinder, then install the new ether cylinder for ether

Have questions with 106673-2870?

Group cross 106673-2870 ZEXEL

Mitsubishi

Mitsubishi

Mitsubishi

106673-2870

INJECTION-PUMP ASSEMBLY