Information injection-pump assembly

ZEXEL

106672-9900

1066729900

MITSUBISHI-HEAV

3256550280

3256550280

Rating:

Service parts 106672-9900 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

32561-69010

12.

Open Pre:MPa(Kqf/cm2)

21.6{220}

15.

NOZZLE SET

Include in #1:

106672-9900

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

106672-9900

1066729900

MITSUBISHI-HEAV

3256550280

3256550280

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8130

Bosch type code

EFEP215A

Nozzle

105780-0050

Bosch type code

DN6TD119NP1T

Nozzle holder

105780-2090

Bosch type code

EFEP215

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-7420

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.9

3.85

3.95

Rack position

Point A R=A

Point A R=A

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

15.4

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

428

419

437

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

4.3+-0.5

Pump speed

r/min

425

425

425

Average injection quantity

mm3/st.

22

19

25

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Idle sub spring setting: L1.

----------

K=12 L1=5.3-0.5mm

----------

----------

K=12 L1=5.3-0.5mm

----------

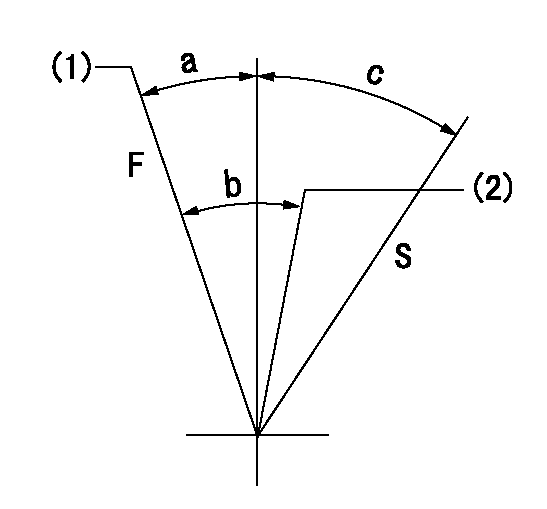

Speed control lever angle

F:Full speed

S:Stop

(1)Set the pump speed at aa. ( At delivery )

(2)Pump speed = bb

----------

aa=900r/min bb=750r/min

----------

a=8deg+-5deg b=9deg+-5deg c=32deg+-3deg

----------

aa=900r/min bb=750r/min

----------

a=8deg+-5deg b=9deg+-5deg c=32deg+-3deg

0000000901

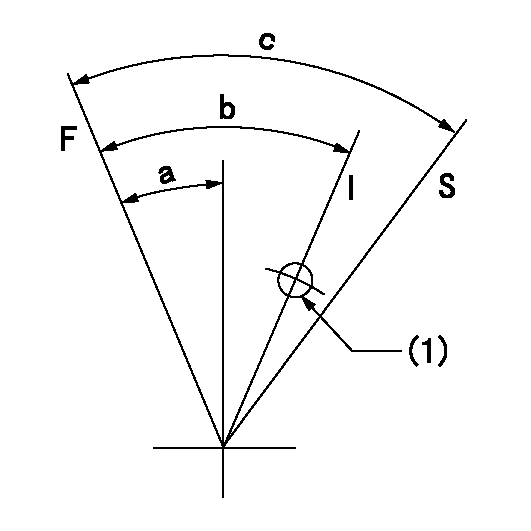

F:Full load

I:Idle

S:Stop

(1)Use the hole at R = aa

----------

aa=25mm

----------

a=26deg+-5deg b=40deg+-5deg c=53deg+-5deg

----------

aa=25mm

----------

a=26deg+-5deg b=40deg+-5deg c=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(20deg)

----------

----------

a=(20deg)

Information:

Regular service intervals, along with close daily visual inspection and the adherence to the instructions and schedules, will assure many hours of trouble-free service. If correction steps are taken immediately on discovery of any abnormal condition, fewer forced stops and more economical operation will result.The Lubrication and Maintenance Chart is intended as a guide and adjustments in the schedule may be necessary, depending on conditions under which the engine is operating. A thorough analysis should be made before adjusting the maintenance schedule.Some items to consider in establishing a new schedule are: Severe dust or dirty conditions, fuel consumption (a good measurement to establish intervals as it indicates the amount of work performed). As a guideline, the 3408 Engine with a 12 gal. (45 litre) (10 imp. gal.) capacity crankcase will use approximately 4000 gal. (15,000 litre) (3332 imp. gal.) between oil changes.* The 3412 Engine with a 16 gal. (60.5 litre) (13 imp. gal.) capacity crankcase will use approximately 5100 gal. (19,200 litre) (4248 imp. gal.) between oil changes. *Reducing or extending the maintenance intervals should be done only after complete study and enough time to gain adequate experience to meet specific operations.*With 0.5% or less fuel sulphur content.Caterpillar scheduled oil sampling: Scheduled oil sampling is a program which analyzes oil samples taken from an engine at regular intervals (usually at oil change periods). This oil analysis does not indicate the condition of the oil; but rather, it is a scheduled procedure to determine engine condition at regular intervals by analyzing lubricating oil for foreign and wear particles.The scheduled oil sampling will give the following benefits:It assures the owner that maintenance has been performed.It will show the first signs of excessive wear, meaning a possible upcoming failure, allowing time for a scheduled repair.It will warm maintenance personnel of improper or lack of maintenance and presence of fuel dilution or antifreeze in oil.It is particularly helpful in preventing wear due to dirt entry from air cleaner or inlet piping.Regular sampling is especially advantageous for new engines to establish wear trends from the beginning. The results of the oil analysis are interpreted by experienced, highly trained personnel. Contact your Caterpillar dealer for detailed information.