Information injection-pump assembly

ZEXEL

106672-9760

1066729760

MITSUBISHI-HEAV

3256550220

3256550220

Rating:

Service parts 106672-9760 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

32561-69010

12.

Open Pre:MPa(Kqf/cm2)

21.6{220}

15.

NOZZLE SET

Include in #1:

106672-9760

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

106672-9760

1066729760

MITSUBISHI-HEAV

3256550220

3256550220

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8130

Bosch type code

EFEP215A

Nozzle

105780-0050

Bosch type code

DN6TD119NP1T

Nozzle holder

105780-2090

Bosch type code

EFEP215

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-3420

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.9

3.85

3.95

Rack position

Point A R=A

Point A R=A

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

15.5

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

415

406

424

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

4.7+-0.5

Pump speed

r/min

370

370

370

Average injection quantity

mm3/st.

35

32

38

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Test data Ex:

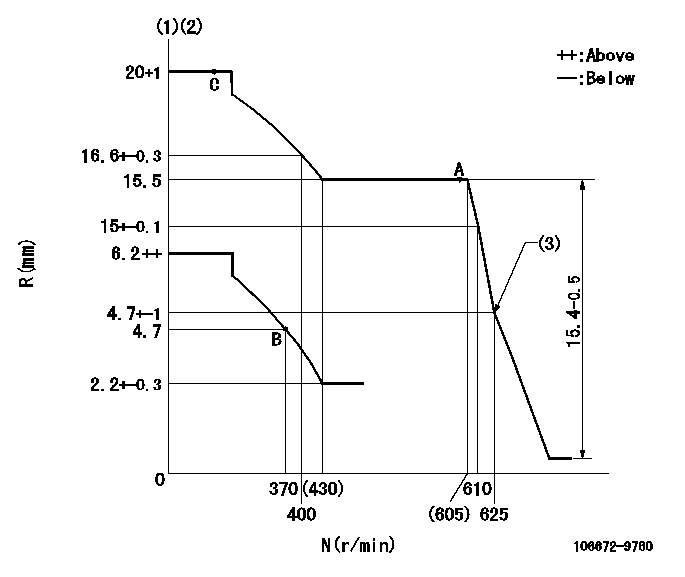

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Idle sub spring setting: L1.

----------

K=7 L1=4.7-0.5mm

----------

----------

K=7 L1=4.7-0.5mm

----------

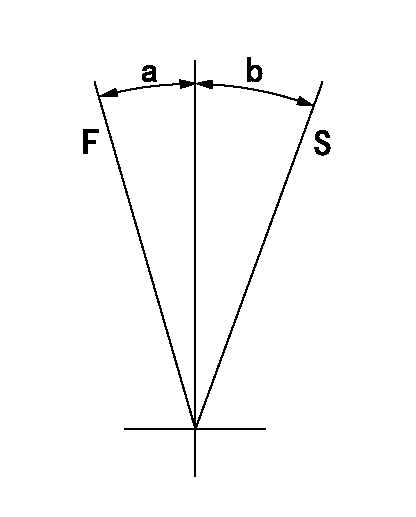

Speed control lever angle

F:Full speed

S:Stop

----------

----------

a=(17deg)+-5deg b=32deg+-3deg

----------

----------

a=(17deg)+-5deg b=32deg+-3deg

0000000901

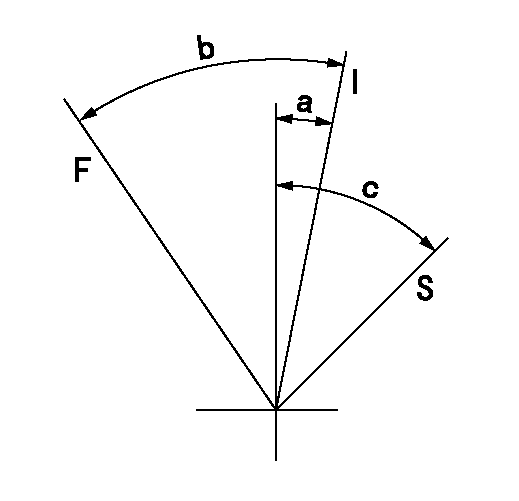

F:Full load

I:Idle

S:Stop

----------

----------

a=5deg+-5deg b=29deg+-5deg c=42deg+-5deg

----------

----------

a=5deg+-5deg b=29deg+-5deg c=42deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(20deg)

----------

----------

a=(20deg)

Information:

Start By:a. remove engine and transmissionb. remove oil pumpc. remove crankshaft rear seal 1. Fasten the engine to tool (A) at the flywheel end as shown.2. Remove bridge (1) and the seals. 3. Remove rear main bearing cap (2). Be sure the location is marked on the main bearing cap before it is removed. The stamped location number is toward the camshaft. 4. Remove upper bearing half (3) with an approved bearing removal tool.

Do not turn the crankshaft in a counterclockwise direction because the tab of the bearing can be pushed between the crankshaft and the engine block. This will cause damage to the crankshaft and engine block.

5. Turn the crankshaft clockwise, as seen from the flywheel, to remove bearing upper half (3). 6. Remove bearing lower half (4) from rear main bearing cap (2). 7. Put the bearing upper half (3) in position on the crankshaft, and use the removal tool to rotate the bearing into position. Turn the crankshaft in a counterclockwise direction to engage bearing tab with the engine block. 8. Install the bearing lower half in the main bearing cap.9. Put a piece of Plastigage (5) across the crankshaft main bearing face. Install main bearings dry when the clearance checks are made. Put clean engine oil on the main bearings for final assembly.10. Put the main bearing cap in position. Put clean engine oil on the threads of the main bearing cap bolts, and tighten them finger tight.11. Tighten the main bearing cap bolts to a torque

Do not turn the crankshaft in a counterclockwise direction because the tab of the bearing can be pushed between the crankshaft and the engine block. This will cause damage to the crankshaft and engine block.

5. Turn the crankshaft clockwise, as seen from the flywheel, to remove bearing upper half (3). 6. Remove bearing lower half (4) from rear main bearing cap (2). 7. Put the bearing upper half (3) in position on the crankshaft, and use the removal tool to rotate the bearing into position. Turn the crankshaft in a counterclockwise direction to engage bearing tab with the engine block. 8. Install the bearing lower half in the main bearing cap.9. Put a piece of Plastigage (5) across the crankshaft main bearing face. Install main bearings dry when the clearance checks are made. Put clean engine oil on the main bearings for final assembly.10. Put the main bearing cap in position. Put clean engine oil on the threads of the main bearing cap bolts, and tighten them finger tight.11. Tighten the main bearing cap bolts to a torque