Information injection-pump assembly

ZEXEL

106672-9551

1066729551

KOMATSU

6128711120

6128711120

Rating:

Cross reference number

ZEXEL

106672-9551

1066729551

KOMATSU

6128711120

6128711120

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8130

Bosch type code

EFEP215A

Nozzle

105780-0050

Bosch type code

EN6TD119NP1T

Nozzle holder

105780-2090

Bosch type code

EFEP215

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131425-1620

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

2.5

2.45

2.55

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

15.3

Pump speed

r/min

1000

1000

1000

Each cylinder's injection qty

mm3/st.

351

344

358

Basic

*

Fixing the lever

*

Boost pressure

kPa

62.7

62.7

Boost pressure

mmHg

470

470

Injection quantity adjustment_02

Adjusting point

B

Rack position

15.9+-0.

5

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

339

329

349

Fixing the lever

*

Boost pressure

kPa

62.7

62.7

Boost pressure

mmHg

470

470

Injection quantity adjustment_03

Adjusting point

C

Rack position

R2-1.6

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

285

275

295

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_04

Adjusting point

D

Rack position

6.5+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

31

27

35

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_05

Adjusting point

E

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

295

285

305

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Rack limit

*

Boost compensator adjustment

Pump speed

r/min

400

400

400

Rack position

R2-1.6

Boost pressure

kPa

18.7

17.4

21.4

Boost pressure

mmHg

140

130

160

Boost compensator adjustment_02

Pump speed

r/min

400

400

400

Rack position

R2(16)

Boost pressure

kPa

49.3

42.6

56

Boost pressure

mmHg

370

320

420

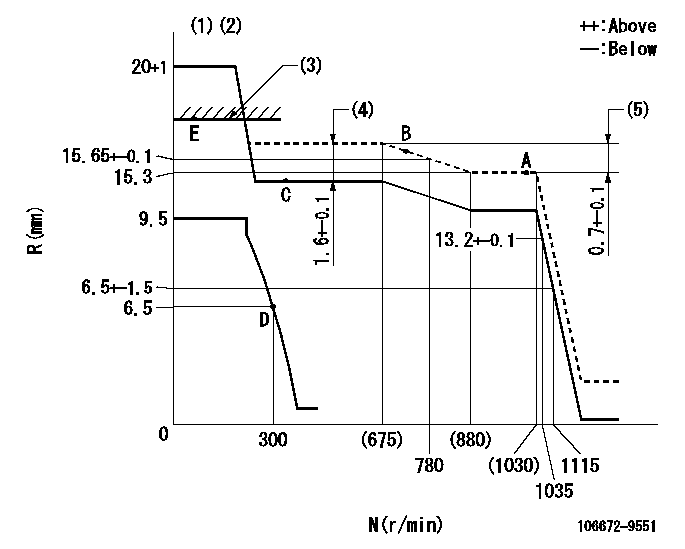

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Boost compensator stroke

(5)Rack difference between N = N1 and N = N2

----------

K=20 N1=1000r/min N2=400r/min

----------

----------

K=20 N1=1000r/min N2=400r/min

----------

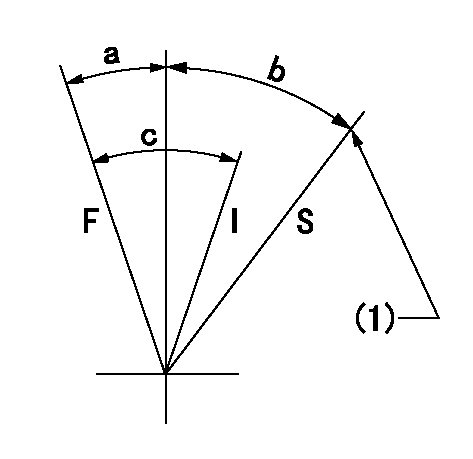

Speed control lever angle

F:Full speed

I:Idle

S:Stop

(1)Stopper bolt setting

----------

----------

a=(16.5deg)+-5deg b=31deg+-3deg c=(32deg)+-5deg

----------

----------

a=(16.5deg)+-5deg b=31deg+-3deg c=(32deg)+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of spline gear's aligning mark at No 1 cylinder's beginning of injection (key position)

(3)-

(4)-

----------

----------

a=(50deg)

----------

----------

a=(50deg)

Information:

D3, 910 and 931

(1) Use two S509 Bolts with 5P4116 Washers to fasten 5G657 Plate (1) to the inside of the radiator guard, in the holes drilled on either page 3 or 4.(2) Install 5P6315 Elbow (2) in 6N7673 Valve Assembly (3). Use 1C569 Bolts with 4B3849 Washers to fasten 6N7673 Valve Assembly (3) and 7N2059 Clamp (4) to plate (1). Use a 5P6314 Sleeve and 5P6313 Nut to connect 5G659 Tube (5) to elbow (2).(3) Remove the plug from the top of air inlet pipe (6) and install 6N7672 Atomizer (7) so the orifice is down (toward the manifold). Connect 7N140 Tube Assembly (8) and 5G660 Tube (9) to tube (5) and atomizer (7) as shown. Put a 3D5102 Grommet on tube (9) and use 8M2772 Clip (10) with an existing valve cover bolt for support of the tube. Tighten the bolt according to valve cover bolt specifications.(4) Remove plug (11) from the heater hose opening on the top left side of the engine timing gear housing (12). Install 6N5899 Switch (13) in the hole for plug (11). Connect 5G663 Wire (14) to switch (13) and one of the wires on valve assembly (3) as shown.(5) For D3 and 931 Machines, connect one end of 5G689 Wire Assembly (15) to the other wire from valve assembly (3). Use the clips that hold wiring harness (16) to fasten wire assembly (15) as shown, and pull the loose end of wire assembly (15) to the start switch. Do not connect wire assembly (15) to the start switch at this time. For 910 Machines, use 161.5" (41 dm) of 5P629 Wire, one 2L8076 Terminal and one 6K1828 Connector to make a wire assembly (15). (6) For all machines, install 3F1006 Switch (17) in the .656" Ø (16.7 Ø) hole that was drilled in the dash. For all earlier D3 and 931 Machines, and for 910 Machines, 80U1-80U3666, remove the 6S4355 Heat-Start Switch and install 6N8941 Start Switch (18). Put electrical tape on the end of the glow plug wire.(7) Connect 6S9586 Wire Assembly (19) to switch (17) and to the accessory (AC) connection on start switch (18). Connect wire (15), from 6N7673 Valve Assembly (3), to the other connection on switch (17) as shown.(8) Install the ether cylinder assembly and fasten it in position with the 7N2059 Clamp (4) that was installed in step 2.(9) Install a 6S9542 Instruction Film in the location that follows: D3, 931 - Install on the dash above switch (17); 910 - Install on the dash at the right side of switch (17).Installation Of 1W162 Engine Arrangement In 910 Machines As Replacement For: (4N303 Engine Arrangement - 80U1-80U6734), (7N3700 Engine Arrangement - 80U6735-up), (7N9433 Or 1W161 Engine Arrangement - 40Y), (7N9437 Or 1W163 Engine Arrangement - 41Y)

Before installation of the 1W162 Engine Arrangement as a replacement for any of the engine arrangements given above, some changes must be made to the new engine arrangement. See the information that follows. After engine installation is complete,

(1) Use two S509 Bolts with 5P4116 Washers to fasten 5G657 Plate (1) to the inside of the radiator guard, in the holes drilled on either page 3 or 4.(2) Install 5P6315 Elbow (2) in 6N7673 Valve Assembly (3). Use 1C569 Bolts with 4B3849 Washers to fasten 6N7673 Valve Assembly (3) and 7N2059 Clamp (4) to plate (1). Use a 5P6314 Sleeve and 5P6313 Nut to connect 5G659 Tube (5) to elbow (2).(3) Remove the plug from the top of air inlet pipe (6) and install 6N7672 Atomizer (7) so the orifice is down (toward the manifold). Connect 7N140 Tube Assembly (8) and 5G660 Tube (9) to tube (5) and atomizer (7) as shown. Put a 3D5102 Grommet on tube (9) and use 8M2772 Clip (10) with an existing valve cover bolt for support of the tube. Tighten the bolt according to valve cover bolt specifications.(4) Remove plug (11) from the heater hose opening on the top left side of the engine timing gear housing (12). Install 6N5899 Switch (13) in the hole for plug (11). Connect 5G663 Wire (14) to switch (13) and one of the wires on valve assembly (3) as shown.(5) For D3 and 931 Machines, connect one end of 5G689 Wire Assembly (15) to the other wire from valve assembly (3). Use the clips that hold wiring harness (16) to fasten wire assembly (15) as shown, and pull the loose end of wire assembly (15) to the start switch. Do not connect wire assembly (15) to the start switch at this time. For 910 Machines, use 161.5" (41 dm) of 5P629 Wire, one 2L8076 Terminal and one 6K1828 Connector to make a wire assembly (15). (6) For all machines, install 3F1006 Switch (17) in the .656" Ø (16.7 Ø) hole that was drilled in the dash. For all earlier D3 and 931 Machines, and for 910 Machines, 80U1-80U3666, remove the 6S4355 Heat-Start Switch and install 6N8941 Start Switch (18). Put electrical tape on the end of the glow plug wire.(7) Connect 6S9586 Wire Assembly (19) to switch (17) and to the accessory (AC) connection on start switch (18). Connect wire (15), from 6N7673 Valve Assembly (3), to the other connection on switch (17) as shown.(8) Install the ether cylinder assembly and fasten it in position with the 7N2059 Clamp (4) that was installed in step 2.(9) Install a 6S9542 Instruction Film in the location that follows: D3, 931 - Install on the dash above switch (17); 910 - Install on the dash at the right side of switch (17).Installation Of 1W162 Engine Arrangement In 910 Machines As Replacement For: (4N303 Engine Arrangement - 80U1-80U6734), (7N3700 Engine Arrangement - 80U6735-up), (7N9433 Or 1W161 Engine Arrangement - 40Y), (7N9437 Or 1W163 Engine Arrangement - 41Y)

Before installation of the 1W162 Engine Arrangement as a replacement for any of the engine arrangements given above, some changes must be made to the new engine arrangement. See the information that follows. After engine installation is complete,