Information injection-pump assembly

ZEXEL

106672-9430

1066729430

Rating:

Cross reference number

ZEXEL

106672-9430

1066729430

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.8

3.75

3.85

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

8.6

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

118.1

116.1

120.1

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Boost pressure

kPa

53.3

53.3

Boost pressure

mmHg

400

400

Injection quantity adjustment_02

Adjusting point

C

Rack position

4.2+-0.5

Pump speed

r/min

325

325

325

Average injection quantity

mm3/st.

13.3

11.8

14.8

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

400

400

400

Rack position

9.9

Boost pressure

kPa

21.3

18.6

24

Boost pressure

mmHg

160

140

180

Boost compensator adjustment_02

Pump speed

r/min

400

400

400

Rack position

10.3

Boost pressure

kPa

40

40

40

Boost pressure

mmHg

300

300

300

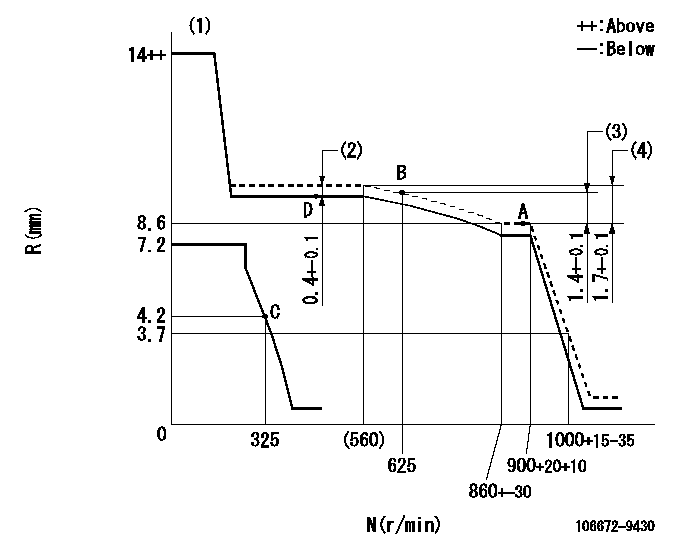

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Boost compensator stroke

(3)Rack difference between N = N1 and N = N2

(4)Rack difference between N = N3 and N = N4

----------

K=13 N1=900r/min N2=625r/min N3=900r/min N4=400r/min

----------

----------

K=13 N1=900r/min N2=625r/min N3=900r/min N4=400r/min

----------

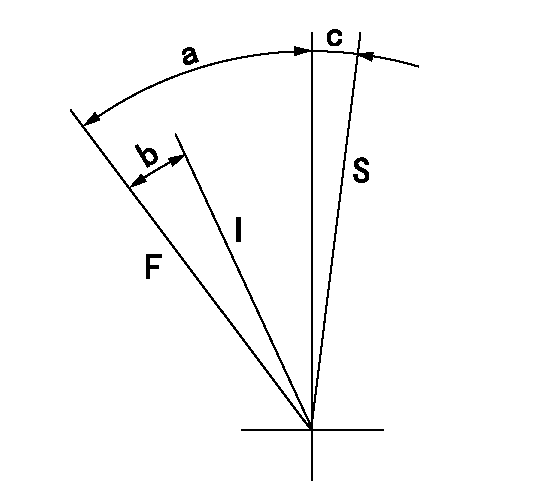

Speed control lever angle

F:Full speed

I:Idle

S:Stop

----------

----------

a=38deg+-5deg b=29deg+-5deg c=0deg+-3deg

----------

----------

a=38deg+-5deg b=29deg+-5deg c=0deg+-3deg

0000001501 LEVER

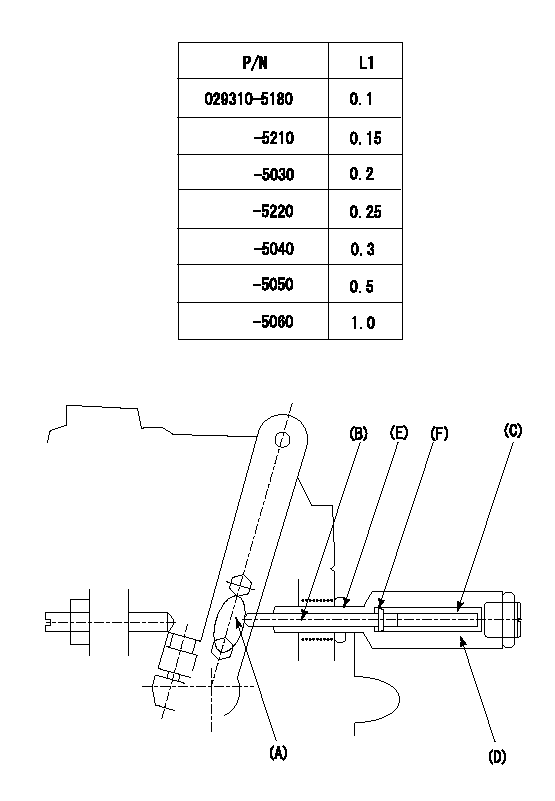

(F) P/N: Part number of the shim

L1:Thickness (mm)

1. Adjustment of the control lever

(1)Perform idling with the control lever (A) contacting the pushrod (B). At this time, confirm that the spring (C) is not compressed by control lever (A)'s operating torque.

(2)To set the stop position, compress spring (C) using the control lever (A) and adjust the rack so that it contacts the guide screw (D) at position L2. Then, set and fix using the lock nut (E). Adjust the rack position L2 at this time using the shim (F).

(3)Confirm that the control lever (A) returns to the idling position when pulled in the stop direction and then released.

----------

L2=0.2~2mm

----------

----------

L2=0.2~2mm

----------

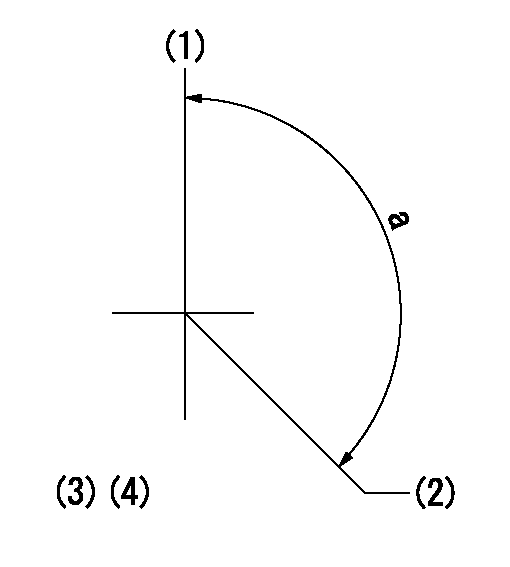

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(150deg)

----------

----------

a=(150deg)

Information:

The information supplied in this service letter may not be valid after the termination date of this program. Do not perform the work outlined in this Service Letter after the termination date without first contacting your Caterpillar product analyst.

Termination Date

August 31, 1997Problem

0R0906, 0R1756, 0R1758, 0R2921, 0R2922, 0R2923, 0R2924, 0R2925, 0R3051, and 0R3052 Remanufactured Unit Injectors with date codes between January 01, 1997 and April 30, 1997 need to be removed from Parts Stock.Action Required

Inspect all 0R0906, 0R1756, 0R1758, 0R2921, 0R2922, 0R2923, 0R2924, 0R2925, 0R3051, and 0R3052 Remanufactured Unit Injectors with date codes between January 01, 1997 and April 30, 1997 from Parts Stock.

The date code can be located below the part name and above the part number on part number tag attached to the box. The date code is formatted as DDMMYYXXX (example; a box marked with a date code of 150195068 would indicate a part manufactured on January 15, 1995 at plant number 068).

If the injector is no longer in the original box, use the date code engraved on the top of the unit injector tappet. It is in the "NUMERAL KOD" format. The code consists of the month and the year.

Where the numbers for the months and years are coded as follows:

January 1997 ... NUDKFebruary 1997... NMDKMarch 1997 ... NEDKApril 1997 ... NRDKTo inspect the injectors, push the rack bar in against the trim adjustment screw (the fuel off position). On the flat "D" section of the rack bar extending out of the injector and beyond the rack teeth, inspect for a shinny grooved machine mark completely across the flat surface and parallel with the rack teeth. This mark is caused by the plunger gear contacting the flat of the rack bar If the mark is present, the injector should be returned to Caterpillar.

Service Claim Allowances

Submit one claim for all 0R0906, 0R1756, 0R1758, 0R2921, 0R2922, 0R2923, 0R2924, 0R2925, 0R3051, and 0R3052 Remanufactured Unit Injectors with date codes between January 01, 1997 and April 30, 1997 removed from Parts Stock.

MEPS dealers are reimbursed for recalled Parts Stock by returning the affected Parts Stock to their administering Caterpillar dealer for replacement.

Parts Disposition

All injectors removed from Parts Stock are to be returned as cores for remanufacturing.

U.S. and Canadian Dealers

Return all 0R0906, 0R1756, 0R1758, 0R2921, 0R2922, 0R2923, 0R2924, 0R2925, 0R3051, and 0R3052 Remanufactured Unit Injectors with date codes between January 01, 1997 and April 30, 1997 that are removed from Parts Stock and a copy of the claim to:

Caterpillar Inc.

Attn: Bill Harland - Warranty Review

501 Cardinal Drive

Corinth, MS 38834

All Other Dealers

Handle the parts in accordance with your Warranty Bulletin on Remanufactured Engines and Components, refer to the topic "Disposition of the Core Under Warranty".

Termination Date

August 31, 1997Problem

0R0906, 0R1756, 0R1758, 0R2921, 0R2922, 0R2923, 0R2924, 0R2925, 0R3051, and 0R3052 Remanufactured Unit Injectors with date codes between January 01, 1997 and April 30, 1997 need to be removed from Parts Stock.Action Required

Inspect all 0R0906, 0R1756, 0R1758, 0R2921, 0R2922, 0R2923, 0R2924, 0R2925, 0R3051, and 0R3052 Remanufactured Unit Injectors with date codes between January 01, 1997 and April 30, 1997 from Parts Stock.

The date code can be located below the part name and above the part number on part number tag attached to the box. The date code is formatted as DDMMYYXXX (example; a box marked with a date code of 150195068 would indicate a part manufactured on January 15, 1995 at plant number 068).

If the injector is no longer in the original box, use the date code engraved on the top of the unit injector tappet. It is in the "NUMERAL KOD" format. The code consists of the month and the year.

Where the numbers for the months and years are coded as follows:

January 1997 ... NUDKFebruary 1997... NMDKMarch 1997 ... NEDKApril 1997 ... NRDKTo inspect the injectors, push the rack bar in against the trim adjustment screw (the fuel off position). On the flat "D" section of the rack bar extending out of the injector and beyond the rack teeth, inspect for a shinny grooved machine mark completely across the flat surface and parallel with the rack teeth. This mark is caused by the plunger gear contacting the flat of the rack bar If the mark is present, the injector should be returned to Caterpillar.

Service Claim Allowances

Submit one claim for all 0R0906, 0R1756, 0R1758, 0R2921, 0R2922, 0R2923, 0R2924, 0R2925, 0R3051, and 0R3052 Remanufactured Unit Injectors with date codes between January 01, 1997 and April 30, 1997 removed from Parts Stock.

MEPS dealers are reimbursed for recalled Parts Stock by returning the affected Parts Stock to their administering Caterpillar dealer for replacement.

Parts Disposition

All injectors removed from Parts Stock are to be returned as cores for remanufacturing.

U.S. and Canadian Dealers

Return all 0R0906, 0R1756, 0R1758, 0R2921, 0R2922, 0R2923, 0R2924, 0R2925, 0R3051, and 0R3052 Remanufactured Unit Injectors with date codes between January 01, 1997 and April 30, 1997 that are removed from Parts Stock and a copy of the claim to:

Caterpillar Inc.

Attn: Bill Harland - Warranty Review

501 Cardinal Drive

Corinth, MS 38834

All Other Dealers

Handle the parts in accordance with your Warranty Bulletin on Remanufactured Engines and Components, refer to the topic "Disposition of the Core Under Warranty".