Information injection-pump assembly

ZEXEL

106672-9311

1066729311

Rating:

Cross reference number

ZEXEL

106672-9311

1066729311

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-3420

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.3

4.25

4.35

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

8.5

Pump speed

r/min

1050

1050

1050

Average injection quantity

mm3/st.

137.2

135.2

139.2

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

3.9+-0.5

Pump speed

r/min

335

335

335

Average injection quantity

mm3/st.

13

11.5

14.5

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Test data Ex:

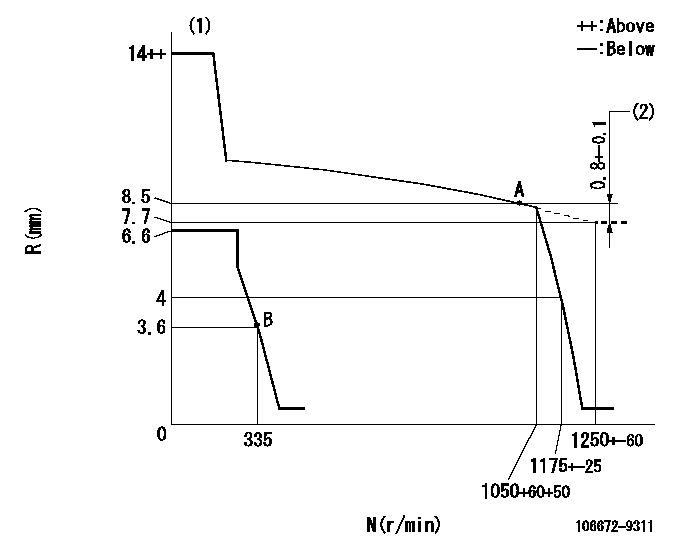

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Rack difference between N = N1 and N = N2

----------

K=11 N1=1330r/min N2=1050r/min

----------

----------

K=11 N1=1330r/min N2=1050r/min

----------

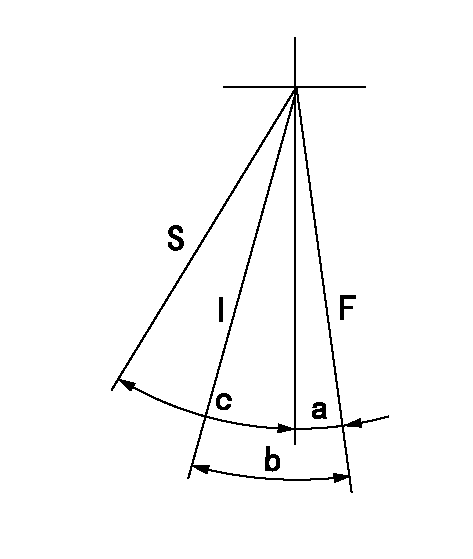

Speed control lever angle

F:Full speed

I:Idle

S:Stop

----------

----------

a=6deg+-5deg b=27deg+-5deg c=32deg+-3deg

----------

----------

a=6deg+-5deg b=27deg+-5deg c=32deg+-3deg

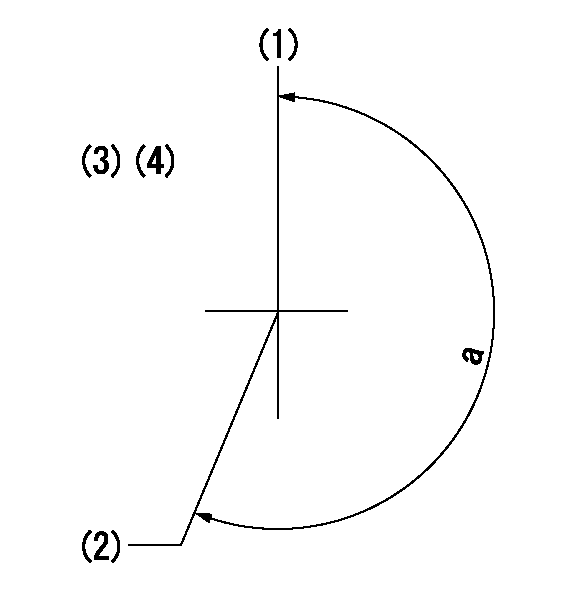

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(260deg)

----------

----------

a=(260deg)

Information:

Problem

Certain 785 and 789 Trucks may experience problems during cold starts. An Automatic Ether Injection System (AEIS) can be installed to improve starting and combustion during cold startups and increase the service life of the engine.

Affected Product

Model & Identification Number

785 (8GB1-417)

789 (9ZC1-439)

Parts Needed

*For use on machines that DO NOT have Payload Monitor System.**For use on machines that DO have Payload Monitor System.***For machines that have Automatic Electronic Traction Aid.Action Required

If so equipped, remove the existing manual type ether injection system.

Follow the procedure in Special Instruction SEHS9293 "Installation of Automatic Ether Injection System (AEIS) " and install the Automatic Ether Injection System (AEIS).

Service Claim Allowances

This is a 9-hour job.

Parts Disposition

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

Certain 785 and 789 Trucks may experience problems during cold starts. An Automatic Ether Injection System (AEIS) can be installed to improve starting and combustion during cold startups and increase the service life of the engine.

Affected Product

Model & Identification Number

785 (8GB1-417)

789 (9ZC1-439)

Parts Needed

*For use on machines that DO NOT have Payload Monitor System.**For use on machines that DO have Payload Monitor System.***For machines that have Automatic Electronic Traction Aid.Action Required

If so equipped, remove the existing manual type ether injection system.

Follow the procedure in Special Instruction SEHS9293 "Installation of Automatic Ether Injection System (AEIS) " and install the Automatic Ether Injection System (AEIS).

Service Claim Allowances

This is a 9-hour job.

Parts Disposition

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.