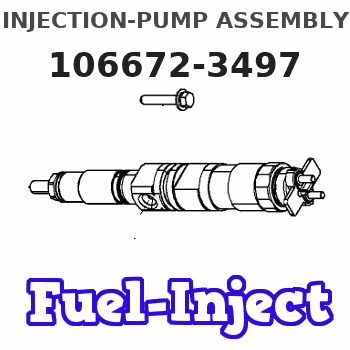

Information injection-pump assembly

BOSCH

F 019 Z10 634

f019z10634

ZEXEL

106672-3497

1066723497

Rating:

Service parts 106672-3497 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

9.

_

11.

Nozzle and Holder

236002211A

12.

Open Pre:MPa(Kqf/cm2)

16.7(170)/27.5(280)

15.

NOZZLE SET

Include in #1:

106672-3497

as INJECTION-PUMP ASSEMBLY

Cross reference number

Zexel num

Bosch num

Firm num

Name

Information:

Disassembly and Reassembly of General Parts

Oil seals

When installing oil seals, observe the following.Installation of Oil Seals to Housings

(a) Check the seal lip for scratches and damage, and be sure to position the lip correctly.(b) Apply a small amount of grease to the periphery (housing contact surface) of the oil seal before installation.(c) Use an oil seal driver that guides the seal lip and presses the seal periphery, as shown in the diagram on the right. Striking the oil seal directly with a hammer causes seal damage and results in oil leaks.

Oil seal driverInstallation of Oil Seals to Shafts

(a) Apply grease to the oil seal lip.(b) Use an oil seal guide similar to the one shown in the diagram when installing an oil seal over the stepped portion, splines, threads or key grooves.

Oil seal guideO-rings

Use an O-ring guide similar to the one shown in the diagram when installing an O-ring over the stepped portion, splines, threads or key grooves. Be sure to apply a small amount of grease to the O-ring before installation.

O-ring guideBearings

(1) When installing a bearing, be sure to push the inner or outer race that fits into the installation position. (When the inner race fits into the installation position, push the inner race into position. When the outer race fits into the installation position, push the outer race into position.) Be sure to use a bearing driver similar to the one shown in the diagram.

Bearing driver(2) Use of a press minimizes the impact on the bearing and ensures proper installation.

Using press for bearing installationLock Plates

Be sure to bend lock plates. The diagram on the right shows the methods of bending representative lock plates.

Bending lock plateSplit Pins and Spring Pins

Generally, new split pins should be installed whenever split pins are removed. Be sure to bend split pins. Be sure to check spring pins for secure installation.

Oil seals

When installing oil seals, observe the following.Installation of Oil Seals to Housings

(a) Check the seal lip for scratches and damage, and be sure to position the lip correctly.(b) Apply a small amount of grease to the periphery (housing contact surface) of the oil seal before installation.(c) Use an oil seal driver that guides the seal lip and presses the seal periphery, as shown in the diagram on the right. Striking the oil seal directly with a hammer causes seal damage and results in oil leaks.

Oil seal driverInstallation of Oil Seals to Shafts

(a) Apply grease to the oil seal lip.(b) Use an oil seal guide similar to the one shown in the diagram when installing an oil seal over the stepped portion, splines, threads or key grooves.

Oil seal guideO-rings

Use an O-ring guide similar to the one shown in the diagram when installing an O-ring over the stepped portion, splines, threads or key grooves. Be sure to apply a small amount of grease to the O-ring before installation.

O-ring guideBearings

(1) When installing a bearing, be sure to push the inner or outer race that fits into the installation position. (When the inner race fits into the installation position, push the inner race into position. When the outer race fits into the installation position, push the outer race into position.) Be sure to use a bearing driver similar to the one shown in the diagram.

Bearing driver(2) Use of a press minimizes the impact on the bearing and ensures proper installation.

Using press for bearing installationLock Plates

Be sure to bend lock plates. The diagram on the right shows the methods of bending representative lock plates.

Bending lock plateSplit Pins and Spring Pins

Generally, new split pins should be installed whenever split pins are removed. Be sure to bend split pins. Be sure to check spring pins for secure installation.