Information injection-pump assembly

BOSCH

9 400 617 078

9400617078

ZEXEL

106672-3282

1066723282

HINO

220005222A

220005222a

Rating:

Cross reference number

BOSCH

9 400 617 078

9400617078

ZEXEL

106672-3282

1066723282

HINO

220005222A

220005222a

Zexel num

Bosch num

Firm num

Name

106672-3282

9 400 617 078

220005222A HINO

INJECTION-PUMP ASSEMBLY

EP1 K

EP1 K

106672-3282

9 400 617 078

S220005222A HINO

INJECTION-PUMP ASSEMBLY

EP1 A K

EP1 A K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve (drive side)

134424-1420

Overflow valve opening pressure (drive side)

kPa

162

147

177

Overflow valve opening pressure (drive side)

kgf/cm2

1.65

1.5

1.8

Overflow valve (governor side)

134424-1720

Overflow valve opening pressure (governor side)

kPa

162

147

177

Overflow valve opening pressure (governor side)

kgf/cm2

1.65

1.5

1.8

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

4.5

4.44

4.5

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.75 60.25

Cal 1-4 deg. 60 59.75 60.25

Difference between angles 2

Cyl.1-2 deg. 120 119.75 120.25

Cyl.1-2 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cal 1-3 deg. 240 239.75 240.25

Cal 1-3 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-5 deg. 300 299.75 300.25

Cal 1-5 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

A

Rack position

8.4

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

146.7

144.7

148.7

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Boost pressure

kPa

32

32

Boost pressure

mmHg

240

240

Injection quantity adjustment_02

Adjusting point

C

Rack position

8.2

Pump speed

r/min

1075

1075

1075

Average injection quantity

mm3/st.

141.1

135.1

147.1

Max. variation between cylinders

%

0

-5

5

Fixing the lever

*

Boost pressure

kPa

32

32

Boost pressure

mmHg

240

240

Injection quantity adjustment_03

Adjusting point

D

Rack position

7.7

Pump speed

r/min

1200

1200

1200

Average injection quantity

mm3/st.

131

126

136

Max. variation between cylinders

%

0

-5

5

Fixing the lever

*

Boost pressure

kPa

32

32

Boost pressure

mmHg

240

240

Injection quantity adjustment_04

Adjusting point

E

Rack position

9.8+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

180.6

177.6

183.6

Fixing the lever

*

Boost pressure

kPa

32

32

Boost pressure

mmHg

240

240

Injection quantity adjustment_05

Adjusting point

G

Rack position

6.3

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

72.9

70.9

74.9

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_06

Adjusting point

H

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

110

110

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_07

Adjusting point

I

Rack position

4.6+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

8.4

5.4

11.4

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

700

700

700

Rack position

6.3

Boost pressure

kPa

3.3

3.3

5.3

Boost pressure

mmHg

25

25

40

Boost compensator adjustment_02

Pump speed

r/min

700

700

700

Rack position

8.4

Boost pressure

kPa

18.7

18.7

18.7

Boost pressure

mmHg

140

140

140

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)RACK LIMIT

(2)Set idle at delivery

(3)Damper spring setting: DL

(4)Rack difference between N = N1 and N = N2

----------

DL=4.4-0.2mm N1=1075r/min N2=700r/min

----------

----------

DL=4.4-0.2mm N1=1075r/min N2=700r/min

----------

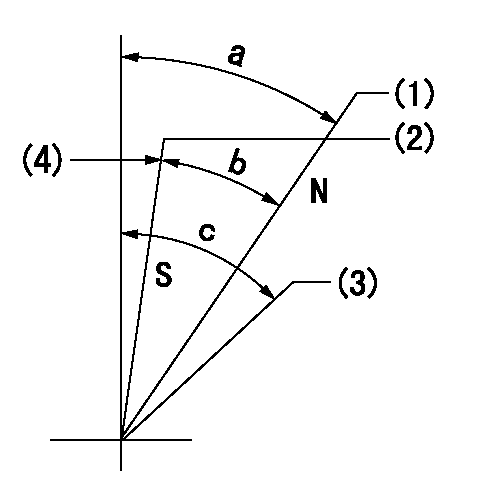

Speed control lever angle

F:Full speed

----------

----------

a=6deg+-5deg

----------

----------

a=6deg+-5deg

0000000901

F:Full load

I:Idle

(1)Set point I

(2)At delivery

----------

----------

a=25deg+-5deg b=39deg+-3deg c=41.5deg+-5deg

----------

----------

a=25deg+-5deg b=39deg+-3deg c=41.5deg+-5deg

Stop lever angle

N:Engine manufacturer's normal use

S:Stop the pump.

(1)Rack position = aa

(2)Rack position bb

(3)Free (at delivery)

(4)Set the stopper bolt (apply red paint).

----------

aa=12mm bb=2.5-0.5mm

----------

a=40deg+-5deg b=30deg+-5deg c=(50deg)

----------

aa=12mm bb=2.5-0.5mm

----------

a=40deg+-5deg b=30deg+-5deg c=(50deg)

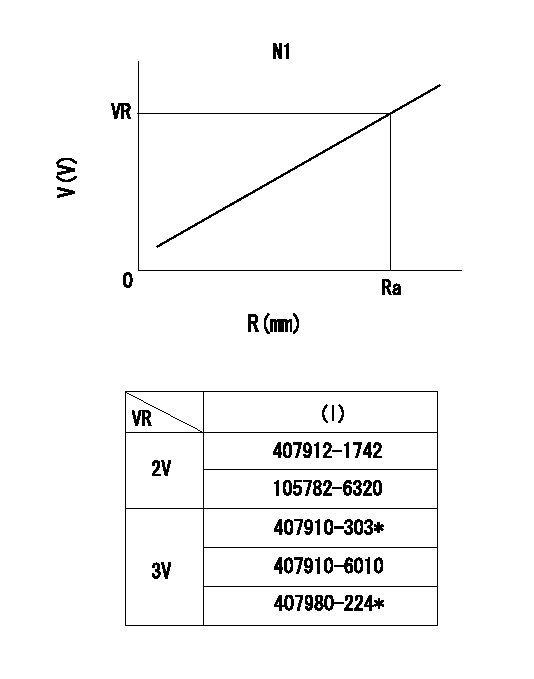

0000001501 RACK SENSOR

R:Rack position (mm)

V:Voltage (V)

After installing the rack sensor, confirm the output value (VR).

----------

N1=700r/min Ra=8.4mm VR=1.7+-0.01V

----------

----------

N1=700r/min Ra=8.4mm VR=1.7+-0.01V

----------

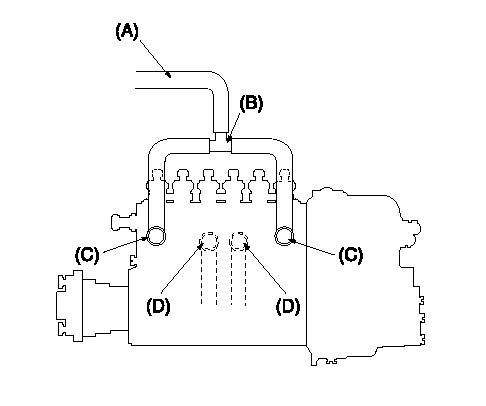

0000001601 Q ADJUSTMENT PIPING

Tester fuel pipe A

(B) branch piping

Fuel inlet C

(D) Overflow valve

Piping at standard injection quantity adjustment

1. Because the pump gallery is divided into two, be careful of the fuel piping at adjustment.

----------

----------

----------

----------

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(0deg)

----------

----------

a=(0deg)

Information:

3-164D, 3-179D, 4-219D, 4-239D, 4-239T, 6-329D, 6-359D, Or 6-359T Engine

Removal

Fig. 1-Oil Cooler LinesDisconnect coolant lines (1, Fig. 1).Remove oil filter (2).

Fig. 2-Oil Cooler NippleUnscrew oil cooler nipple (Fig. 2) and lift oil cooler off of cylinder block.Remove four sided packing from bottom of oil cooler.Repair

Pressure check the coolant side of the oil cooler using 15 psi (103 kPa) (1 bar) maximum air pressure.Remove oil cooler bypass valve by driving it out the bottom of the oil cooler from the top side.

Fig. 3-Oil Cooler Bypass Valve and SpringInspect bypass valve and spring (Fig. 3) for damage and replace as necessary.Installation

Fig. 4-Four Sided PackingInstall new four sided packing (Fig. 4) on bottom of oil cooler.Position oil cooler on engine and install oil cooler nipple.

Fig. 5-Oil Cooler NippleOil cooler nipple torque (Fig. 5) ... 20 to 25 lb-ft(27 to 34 N m) (3.0 to 3.5 kg-m)Connect coolant hoses to oil cooler and install new oil filter (Group 0407).4-276D, 4-276T, 6-414D Or 6414T Engine

Removal

Fig. 6-Oil Cooler Assembly RemovalDisconnect coolant lines (1, Fig. 6) and remove oil filter (2).Remove oil cooler assembly attaching cap screws (3).Remove oil filter housing (4) from oil cooler.Repair

Remove top and bottom covers.

Fig. 7-Remove Oil CoolerUsing a suitable driver, drive oil cooler out of housing from bottom side (Fig. 7).

Fig. 8-Remove Oil Cooler Relief ValveDrive oil cooler bypass valve out the bottom from the top using a pin punch against the top of the valve (Fig. 8).

Fig. 9-Oil CoolerInspect oil cooler for damage or build-up of foreign material and clean as needed.The oil cooler can be pressure checked with a maximum of 50 psi (345 kPa) (3 bar) air pressure.

Fig. 10-Oil Cooler Bypass Valve Spring LengthCheck oil cooler bypass valve spring length:Valve spring length (Fig. 10) ... 1.91 inch(48.5 mm)when compressed with ... 29.5 to 37.5 lb(131 to 167 N)

Fig. 11-Remove O-RingsRemove O-rings from housing at bottom of oil cooler bore.Remove all gasket residue from parts.Installation

Fig. 12-Install Oil Cooler Relief ValvePosition oil cooler relief valve spring (1, Fig. 12), valve (2), and valve seat (3) in bore in bottom of housing (4).

Fig. 13-Drive Oil Cooler Relief Valve SeatUsing a suitable driver (Fig. 13), drive the valve seat into the housing until the seat bottoms.

Fig. 14-O-Ring InstallationInstall new O-rings in housing at bottom of oil cooler bore, black O-ring in upper groove (A, Fig. 14) and red O-ring in lower groove (B).Using new gasket, install oil cooler in housing from top side, being careful not to shear O-rings.Using new gaskets, install top and bottom covers and oil filter housing.Position oil cooler assembly on engine and install cap screws.Connect oil cooler coolant lines and install a new oil filter.

Removal

Fig. 1-Oil Cooler LinesDisconnect coolant lines (1, Fig. 1).Remove oil filter (2).

Fig. 2-Oil Cooler NippleUnscrew oil cooler nipple (Fig. 2) and lift oil cooler off of cylinder block.Remove four sided packing from bottom of oil cooler.Repair

Pressure check the coolant side of the oil cooler using 15 psi (103 kPa) (1 bar) maximum air pressure.Remove oil cooler bypass valve by driving it out the bottom of the oil cooler from the top side.

Fig. 3-Oil Cooler Bypass Valve and SpringInspect bypass valve and spring (Fig. 3) for damage and replace as necessary.Installation

Fig. 4-Four Sided PackingInstall new four sided packing (Fig. 4) on bottom of oil cooler.Position oil cooler on engine and install oil cooler nipple.

Fig. 5-Oil Cooler NippleOil cooler nipple torque (Fig. 5) ... 20 to 25 lb-ft(27 to 34 N m) (3.0 to 3.5 kg-m)Connect coolant hoses to oil cooler and install new oil filter (Group 0407).4-276D, 4-276T, 6-414D Or 6414T Engine

Removal

Fig. 6-Oil Cooler Assembly RemovalDisconnect coolant lines (1, Fig. 6) and remove oil filter (2).Remove oil cooler assembly attaching cap screws (3).Remove oil filter housing (4) from oil cooler.Repair

Remove top and bottom covers.

Fig. 7-Remove Oil CoolerUsing a suitable driver, drive oil cooler out of housing from bottom side (Fig. 7).

Fig. 8-Remove Oil Cooler Relief ValveDrive oil cooler bypass valve out the bottom from the top using a pin punch against the top of the valve (Fig. 8).

Fig. 9-Oil CoolerInspect oil cooler for damage or build-up of foreign material and clean as needed.The oil cooler can be pressure checked with a maximum of 50 psi (345 kPa) (3 bar) air pressure.

Fig. 10-Oil Cooler Bypass Valve Spring LengthCheck oil cooler bypass valve spring length:Valve spring length (Fig. 10) ... 1.91 inch(48.5 mm)when compressed with ... 29.5 to 37.5 lb(131 to 167 N)

Fig. 11-Remove O-RingsRemove O-rings from housing at bottom of oil cooler bore.Remove all gasket residue from parts.Installation

Fig. 12-Install Oil Cooler Relief ValvePosition oil cooler relief valve spring (1, Fig. 12), valve (2), and valve seat (3) in bore in bottom of housing (4).

Fig. 13-Drive Oil Cooler Relief Valve SeatUsing a suitable driver (Fig. 13), drive the valve seat into the housing until the seat bottoms.

Fig. 14-O-Ring InstallationInstall new O-rings in housing at bottom of oil cooler bore, black O-ring in upper groove (A, Fig. 14) and red O-ring in lower groove (B).Using new gasket, install oil cooler in housing from top side, being careful not to shear O-rings.Using new gaskets, install top and bottom covers and oil filter housing.Position oil cooler assembly on engine and install cap screws.Connect oil cooler coolant lines and install a new oil filter.

Have questions with 106672-3282?

Group cross 106672-3282 ZEXEL

Hino

106672-3282

9 400 617 078

220005222A

INJECTION-PUMP ASSEMBLY

EP1

EP1

106672-3282

9 400 617 078

S220005222A

INJECTION-PUMP ASSEMBLY

EP1

EP1