Information injection-pump assembly

BOSCH

9 400 617 077

9400617077

ZEXEL

106672-3272

1066723272

HINO

220005212A

220005212a

Rating:

Service parts 106672-3272 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

236001642A

12.

Open Pre:MPa(Kqf/cm2)

16.7(170)/23.5(240)

15.

NOZZLE SET

Include in #1:

106672-3272

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 617 077

9400617077

ZEXEL

106672-3272

1066723272

HINO

220005212A

220005212a

Zexel num

Bosch num

Firm num

Name

106672-3272

9 400 617 077

220005212A HINO

INJECTION-PUMP ASSEMBLY

EP1 A * K 14CA PE6P,6PD PE

EP1 A * K 14CA PE6P,6PD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve (drive side)

134424-1420

Overflow valve opening pressure (drive side)

kPa

162

147

177

Overflow valve opening pressure (drive side)

kgf/cm2

1.65

1.5

1.8

Overflow valve (governor side)

134424-1720

Overflow valve opening pressure (governor side)

kPa

162

147

177

Overflow valve opening pressure (governor side)

kgf/cm2

1.65

1.5

1.8

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

4.5

4.44

4.5

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.75 60.25

Cal 1-4 deg. 60 59.75 60.25

Difference between angles 2

Cyl.1-2 deg. 120 119.75 120.25

Cyl.1-2 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cal 1-3 deg. 240 239.75 240.25

Cal 1-3 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-5 deg. 300 299.75 300.25

Cal 1-5 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

A

Rack position

8.4

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

146.7

144.7

148.7

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Boost pressure

kPa

32

32

Boost pressure

mmHg

240

240

Injection quantity adjustment_02

Adjusting point

C

Rack position

8.2

Pump speed

r/min

1075

1075

1075

Average injection quantity

mm3/st.

141.1

135.1

147.1

Max. variation between cylinders

%

0

-5

5

Fixing the lever

*

Boost pressure

kPa

32

32

Boost pressure

mmHg

240

240

Injection quantity adjustment_03

Adjusting point

D

Rack position

7.7

Pump speed

r/min

1200

1200

1200

Average injection quantity

mm3/st.

131

126

136

Max. variation between cylinders

%

0

-5

5

Fixing the lever

*

Boost pressure

kPa

32

32

Boost pressure

mmHg

240

240

Injection quantity adjustment_04

Adjusting point

E

Rack position

9.8+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

180.6

177.6

183.6

Fixing the lever

*

Boost pressure

kPa

32

32

Boost pressure

mmHg

240

240

Injection quantity adjustment_05

Adjusting point

G

Rack position

6.3

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

72.9

70.9

74.9

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_06

Adjusting point

H

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

110

110

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_07

Adjusting point

I

Rack position

4.6+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

8.4

5.4

11.4

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

700

700

700

Rack position

6.3

Boost pressure

kPa

3.3

3.3

5.3

Boost pressure

mmHg

25

25

40

Boost compensator adjustment_02

Pump speed

r/min

700

700

700

Rack position

8.4

Boost pressure

kPa

18.7

18.7

18.7

Boost pressure

mmHg

140

140

140

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Lever ratio: RT

(2)Target shim dimension: TH

(3)RACK LIMIT

(4)Set idle at delivery

(5)Damper spring setting: DL

(6)Rack difference between N = N1 and N = N2

----------

RT=0.8 TH=1.7mm DL=4.4-0.2mm N1=1075r/min N2=700r/min

----------

----------

RT=0.8 TH=1.7mm DL=4.4-0.2mm N1=1075r/min N2=700r/min

----------

Speed control lever angle

F:Full speed

----------

----------

a=6deg+-5deg

----------

----------

a=6deg+-5deg

0000000901

F:Full load

I:Idle

(1)Set point I

(2)At delivery

----------

----------

a=25deg+-5deg b=39deg+-3deg c=41.5deg+-5deg

----------

----------

a=25deg+-5deg b=39deg+-3deg c=41.5deg+-5deg

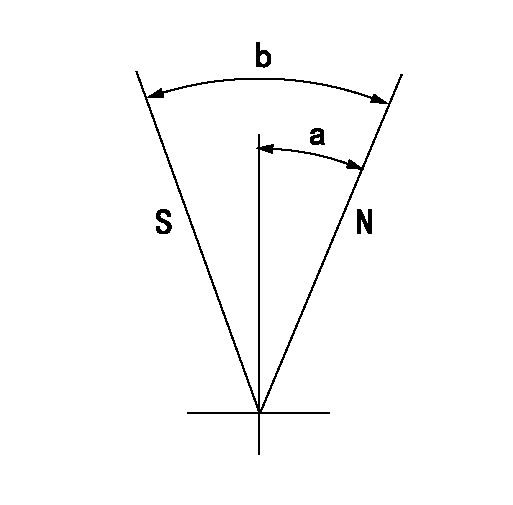

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=40deg+-5deg b=50deg+-5deg

----------

----------

a=40deg+-5deg b=50deg+-5deg

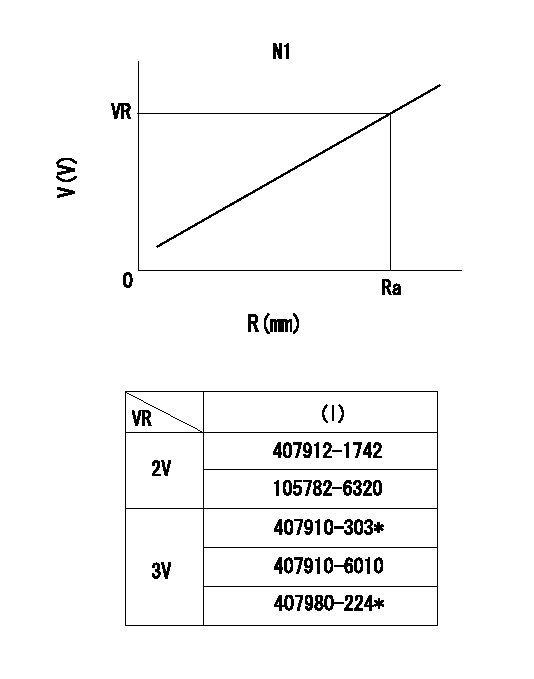

0000001501 RACK SENSOR

R:Rack position (mm)

V:Voltage (V)

After installing the rack sensor, confirm the output value (VR).

----------

N1=700r/min Ra=8.4mm VR=1.7+-0.01V

----------

----------

N1=700r/min Ra=8.4mm VR=1.7+-0.01V

----------

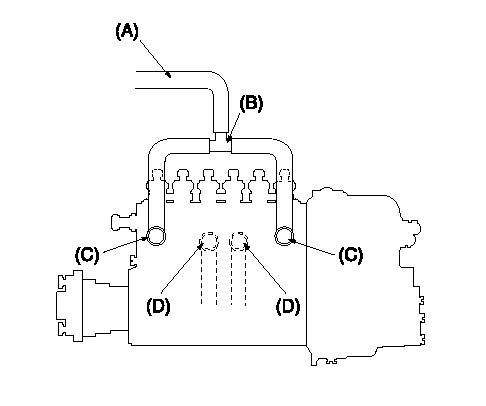

0000001601 Q ADJUSTMENT PIPING

Tester fuel pipe A

(B) branch piping

Fuel inlet C

(D) Overflow valve

Piping at standard injection quantity adjustment

1. Because the pump gallery is divided into two, be careful of the fuel piping at adjustment.

----------

----------

----------

----------

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(0deg)

----------

----------

a=(0deg)

Information:

Fig. 4-Axial Bearing Movement CheckFasten dial indicator to turbine housing so that the indicator tip rests on the end of the shaft (Fig. 4).Move the shaft back and forth axially by hand. The total axial movement of the shaft should be 0.001 to 0.004 in. (0.03 to 0.10 mm). If not repair or replace unit.Repair

As each part is removed, place it in a clean protective container.Refer to Fig. 6 for part identification and relationship.

Fig. 5-Turbine Housing RemovalScribe a line on the mating surfaces of the turbine housing (1, Fig. 5) and center housing (2) to aid in alignment during reassembly.Remove the turbine housing-to-center housing cap screws (5, Fig. 5), lock plates (3), and clamps (4). Carefully remove turbine housing.

Fig. 6-Turbocharger Exploded View

Fig. 7-Removing Compressor (Impeller)Mount a suitable holding fixture (1, Fig. 7) (see Group 0499 Special Tools - Turbocharger) in a vise.Insert the turbine wheel into the fixture.Use a double universal socket to remove the compressor wheel retaining nut to avoid possible bending of the shaft.Remove the impeller (2, Fig. 7) from the shaft.

Fig. 8-Shaft and Wheel AssemblyRemove the turbine wheel and shaft assembly (3, Fig. 8) from the center housing keeping it centered until it is clear of the housing. Fig. 8 shows the turbine wheel assembly (1). The piston ring (2) can now be removed.Remove the back plate to center housing cap screw (16, Fig. 6) and lock plates (15).Carefully remove back plate by tapping with a soft mallet.

Fig. 9-Back Plate Assembly IMPORTANT: Back plate (2, Fig. 9) and the spring (1) are sold only as an assembly. The installed depth of the spring is a controlled dimension. Therefore, do not remove or replace the spring by itself. Cleaning can be done without removing the spring from the back plate.

Fig. 10-Removing Thrust Collar and Thrust WasherRemove the thrust collar (2, Fig. 10) and thrust washer (3) as shown in Fig. 10. Remove the O-ring (1) from housing and piston ring (4) from thrust collar.

Fig. 11-Retaining Ring and Bearing RemovalRemove retaining rings (2, Fig. 11) with a No. 501 Waldes Truarc Snap Ring Pliers, if snap rings are used, and bearings (1) from both sides of the center housing.Cleaning

Before cleaning, inspect parts for signs of burning, rubbing, or other damage which might not be evident after cleaning.Soak all parts in clean carbon solvent for approximately 25 minutes. After soaking use a stiff bristle brush to remove all dirt particles. Dry parts thoroughly. Normally, a light accumulation of carbon deposits will not affect turbine wheel operation.Inspection

Replace the following parts: O-ring (13, Fig. 6), lock plates (6, 15, and 21) piston rings (8 and 18), retaining rings (11), and all damaged nuts and bolts. If bearings and thrust washers show signs of nicks, scores, shellac deposits, or foreign material embedment, replace them.After cleaning, if any of the parts in the assembly show signs of rubbing, scoring, scratches, or seizure, replace them.Assembly

Be sure each part is clean before assembling. As parts are assembled, cover openings to prevent entry of dirt

Have questions with 106672-3272?

Group cross 106672-3272 ZEXEL

Hino

106672-3272

9 400 617 077

220005212A

INJECTION-PUMP ASSEMBLY

EP1

EP1