Information injection-pump assembly

BOSCH

9 400 617 076

9400617076

ZEXEL

106672-3253

1066723253

HINO

220004985A

220004985a

Rating:

Service parts 106672-3253 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

236001740A

12.

Open Pre:MPa(Kqf/cm2)

16.7(170)/27.5(280)

15.

NOZZLE SET

Include in #1:

106672-3253

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 617 076

9400617076

ZEXEL

106672-3253

1066723253

HINO

220004985A

220004985a

Zexel num

Bosch num

Firm num

Name

106672-3253

9 400 617 076

220004985A HINO

INJECTION-PUMP ASSEMBLY

EP2 K

EP2 K

106672-3253

9 400 617 076

S220004985A HINO

INJECTION-PUMP ASSEMBLY

EP2 A K

EP2 A K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve (drive side)

134424-1420

Overflow valve opening pressure (drive side)

kPa

162

147

177

Overflow valve opening pressure (drive side)

kgf/cm2

1.65

1.5

1.8

Overflow valve (governor side)

134424-1720

Overflow valve opening pressure (governor side)

kPa

162

147

177

Overflow valve opening pressure (governor side)

kgf/cm2

1.65

1.5

1.8

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

4.5

4.44

4.5

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.75 60.25

Cal 1-4 deg. 60 59.75 60.25

Difference between angles 2

Cyl.1-2 deg. 120 119.75 120.25

Cyl.1-2 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cal 1-3 deg. 240 239.75 240.25

Cal 1-3 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-5 deg. 300 299.75 300.25

Cal 1-5 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

A

Rack position

8.8

Pump speed

r/min

650

650

650

Average injection quantity

mm3/st.

173

171

175

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Boost pressure

kPa

53.3

53.3

Boost pressure

mmHg

400

400

Injection quantity adjustment_02

Adjusting point

B

Rack position

9.1

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

183.5

180.5

186.5

Max. variation between cylinders

%

0

-5

5

Fixing the lever

*

Boost pressure

kPa

53.3

53.3

Boost pressure

mmHg

400

400

Injection quantity adjustment_03

Adjusting point

C

Rack position

8.8

Pump speed

r/min

850

850

850

Average injection quantity

mm3/st.

171

165

177

Fixing the lever

*

Boost pressure

kPa

53.3

53.3

Boost pressure

mmHg

400

400

Injection quantity adjustment_04

Adjusting point

D

Rack position

8.4

Pump speed

r/min

1050

1050

1050

Average injection quantity

mm3/st.

160.5

157.5

163.5

Max. variation between cylinders

%

0

-5

5

Fixing the lever

*

Boost pressure

kPa

53.3

53.3

Boost pressure

mmHg

400

400

Injection quantity adjustment_05

Adjusting point

E

Rack position

7.4

Pump speed

r/min

1150

1150

1150

Average injection quantity

mm3/st.

137

132

142

Fixing the lever

*

Boost pressure

kPa

53.3

53.3

Boost pressure

mmHg

400

400

Injection quantity adjustment_06

Adjusting point

F

Rack position

9.2+0.2

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

186

180

192

Fixing the lever

*

Boost pressure

kPa

53.3

53.3

Boost pressure

mmHg

400

400

Rack limit

*

Injection quantity adjustment_07

Adjusting point

G

Rack position

6.4

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

86

84

88

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_08

Adjusting point

I

Rack position

4.6+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

11

8

14

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

650

650

650

Rack position

6.4

Boost pressure

kPa

9.3

7.3

9.3

Boost pressure

mmHg

70

55

70

Boost compensator adjustment_02

Pump speed

r/min

650

650

650

Rack position

8.8

Boost pressure

kPa

40

40

40

Boost pressure

mmHg

300

300

300

Test data Ex:

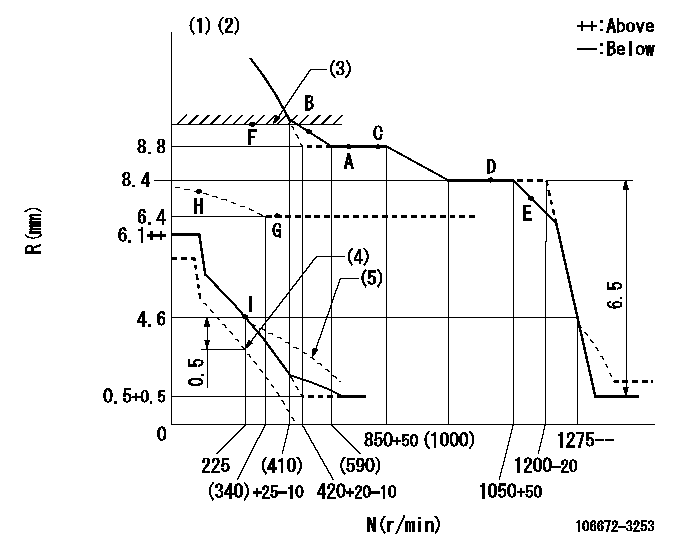

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Lever ratio: RT

(2)Target shim dimension: TH

(3)RACK LIMIT: RAL

(4)Set idle at delivery

(5)Damper spring setting: DL

----------

RT=0.8 TH=1.5mm RAL=9.2+0.2mm DL=4.4-0.2mm

----------

----------

RT=0.8 TH=1.5mm RAL=9.2+0.2mm DL=4.4-0.2mm

----------

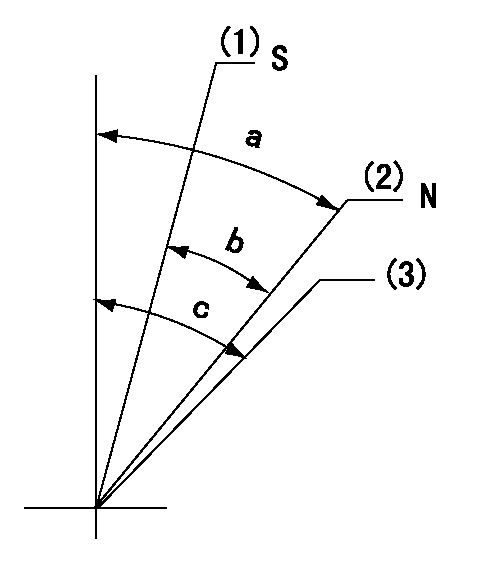

Speed control lever angle

F:Full speed

----------

----------

a=8deg+-5deg

----------

----------

a=8deg+-5deg

0000000901

F:Full load

I:Idle

(1)Set point I

(2)At delivery

----------

----------

a=25deg+-5deg b=45deg+-3deg c=47deg+-5deg

----------

----------

a=25deg+-5deg b=45deg+-3deg c=47deg+-5deg

Stop lever angle

N:Engine manufacturer's normal use

S:Stop the pump.

(1)Set the stopper bolt at rack = aa (apply red paint).

(2)Rack position bb

(3)Free (at delivery)

----------

aa=2.5-0.5mm bb=12mm

----------

a=40deg+-5deg b=30deg+-5deg c=(50deg)

----------

aa=2.5-0.5mm bb=12mm

----------

a=40deg+-5deg b=30deg+-5deg c=(50deg)

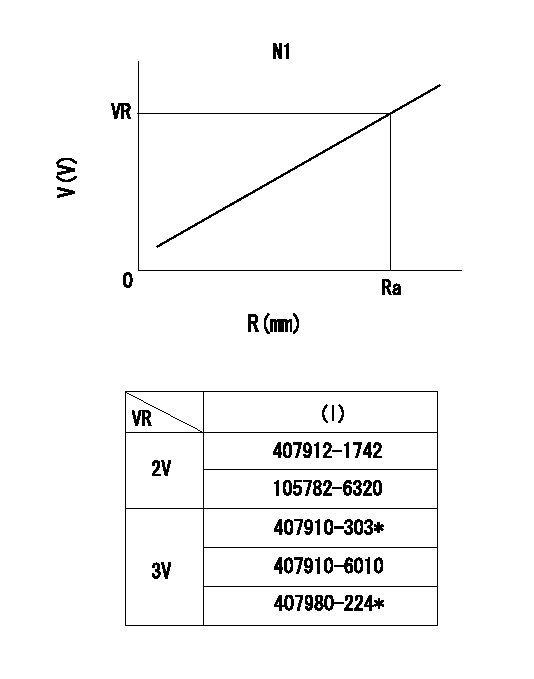

0000001501 RACK SENSOR

R:Rack position (mm)

V:Voltage (V)

After installing the rack sensor, confirm the output value (VR).

----------

N1=650r/min Ra=8.8mm VR=1.7+-0.01V

----------

----------

N1=650r/min Ra=8.8mm VR=1.7+-0.01V

----------

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(0deg)

----------

----------

a=(0deg)

Information:

Repair

Pistons

See Group 0404 for piston-to-cylinder liner measurements.Remove piston rings. IMPORTANT: Do not soak pistons more than 60 minutes.

Avoid contact of solution with skin or eyes.

Soak pistons in 50 percent solution of "Mr. Clean" (or equivalent) and water for 30 to 60 minutes. IMPORTANT: Never clean pistons with wire brush or abrasives.Scrub piston with stiff bristle brush.Rinse pistons in clean water and dry with clean towels. Two different types of pistons marked "B" and "H" on their top face can be selectively installed on 3179D, 4239 D & T, and 6359 D & T engines for a better dead space control inside the cylinder. The difference between the two pistons is 0.006 inch (0.15 mm) on the distance between the piston pin center and the piston top.When replacing pistons, install pistons of the same type as the original.When replacing cylinder block or when mark on piston is no longer visible, determine piston type as follows using gauge KCD-10003.Install cylinder liners and crankshaft with bearings in cylinder block.Secure cylinder liners, using cap screws and washers.Install a "B" type piston with its connecting rod and secure with cap.

Fig. 3A-Determining Type of Piston Using Gauge KCD-10003Place gauge KCD-10003 on liner flange and press downward (3A).Turn crankshaft until piston is in "TDC" position.When piston lightly touches gauge then use "B" type pistons.When pisotn does not contact gauge, then use "H" type pistons.If no gauge is available, proceed as follows:Install a "B" type piston with its connecting rod and secure with cap.Using a dial indicator measure protrusion of each piston (at TDC) above face of cylinder block. Measure at cylinder block centerlineInstall a "B" type piston if protrusion is above or equal to 0.004 in. (0.1 mm) and an "H" type piston if protrusion is below 0.004 in. (0.1 mm). IMPORTANT: Maximum allowable piston standout is 0.012 in. (0.30 mm).Piston Rings and Ring Grooves

Do not re-use piston rings.

Fig. 4-JDE-62 Ring Groove Wear GaugeUsing JDE-62 Ring Groove Wear Gauge (Fig. 4), measure top ring groove. If gauge shoulders contact the ring land, groove is excessively worn.Measure rectangular ring grooves with proper new ring and a feeler gauge.

Fig. 5-Measure Ring GroovesRing groove clearance (maximum) (Fig. 5) ... 0.008 inch(0.20 mm)Piston Pin Bore

Fig. 6-Piston Pin AssemblyPiston pins must fit piston pin bore with a thumb press fit (Fig. 6).Replace piston if piston pin bore is worn.Piston Pin Bushing

Fig. 7-Piston PinMeasure piston pin bushing inside diameter (Fig. 8) with bushing in connecting rod.Piston pin bushing size; If piston pin size is not within specifications, install a new one.Piston Pin Bushing

Fig. 8-Piston Pin BushingMeasure piston pin bushing inside diameter (Fig. 8) with bushing in connecting rod.Piston pin bushing size; Check piston pin size (Group 0403, above).Find the difference, piston pin/bushing clearance, between the piston pin size and the bushing size. The clearance (Fig. 9) must be 0.0008 to 0.0022 in. (0.02 to 0.06 mm).

Fig. 9-Piston Pin/Bushing ClearanceIf bushing size is not within specifications, install a new one.

Fig. 10-Bushing Remover and InstallerUsing the bushing remover and installer listed below,

Pistons

See Group 0404 for piston-to-cylinder liner measurements.Remove piston rings. IMPORTANT: Do not soak pistons more than 60 minutes.

Avoid contact of solution with skin or eyes.

Soak pistons in 50 percent solution of "Mr. Clean" (or equivalent) and water for 30 to 60 minutes. IMPORTANT: Never clean pistons with wire brush or abrasives.Scrub piston with stiff bristle brush.Rinse pistons in clean water and dry with clean towels. Two different types of pistons marked "B" and "H" on their top face can be selectively installed on 3179D, 4239 D & T, and 6359 D & T engines for a better dead space control inside the cylinder. The difference between the two pistons is 0.006 inch (0.15 mm) on the distance between the piston pin center and the piston top.When replacing pistons, install pistons of the same type as the original.When replacing cylinder block or when mark on piston is no longer visible, determine piston type as follows using gauge KCD-10003.Install cylinder liners and crankshaft with bearings in cylinder block.Secure cylinder liners, using cap screws and washers.Install a "B" type piston with its connecting rod and secure with cap.

Fig. 3A-Determining Type of Piston Using Gauge KCD-10003Place gauge KCD-10003 on liner flange and press downward (3A).Turn crankshaft until piston is in "TDC" position.When piston lightly touches gauge then use "B" type pistons.When pisotn does not contact gauge, then use "H" type pistons.If no gauge is available, proceed as follows:Install a "B" type piston with its connecting rod and secure with cap.Using a dial indicator measure protrusion of each piston (at TDC) above face of cylinder block. Measure at cylinder block centerlineInstall a "B" type piston if protrusion is above or equal to 0.004 in. (0.1 mm) and an "H" type piston if protrusion is below 0.004 in. (0.1 mm). IMPORTANT: Maximum allowable piston standout is 0.012 in. (0.30 mm).Piston Rings and Ring Grooves

Do not re-use piston rings.

Fig. 4-JDE-62 Ring Groove Wear GaugeUsing JDE-62 Ring Groove Wear Gauge (Fig. 4), measure top ring groove. If gauge shoulders contact the ring land, groove is excessively worn.Measure rectangular ring grooves with proper new ring and a feeler gauge.

Fig. 5-Measure Ring GroovesRing groove clearance (maximum) (Fig. 5) ... 0.008 inch(0.20 mm)Piston Pin Bore

Fig. 6-Piston Pin AssemblyPiston pins must fit piston pin bore with a thumb press fit (Fig. 6).Replace piston if piston pin bore is worn.Piston Pin Bushing

Fig. 7-Piston PinMeasure piston pin bushing inside diameter (Fig. 8) with bushing in connecting rod.Piston pin bushing size; If piston pin size is not within specifications, install a new one.Piston Pin Bushing

Fig. 8-Piston Pin BushingMeasure piston pin bushing inside diameter (Fig. 8) with bushing in connecting rod.Piston pin bushing size; Check piston pin size (Group 0403, above).Find the difference, piston pin/bushing clearance, between the piston pin size and the bushing size. The clearance (Fig. 9) must be 0.0008 to 0.0022 in. (0.02 to 0.06 mm).

Fig. 9-Piston Pin/Bushing ClearanceIf bushing size is not within specifications, install a new one.

Fig. 10-Bushing Remover and InstallerUsing the bushing remover and installer listed below,

Have questions with 106672-3253?

Group cross 106672-3253 ZEXEL

Hino

106672-3253

9 400 617 076

220004985A

INJECTION-PUMP ASSEMBLY

EP2

EP2

106672-3253

9 400 617 076

S220004985A

INJECTION-PUMP ASSEMBLY

EP2

EP2