Information injection-pump assembly

ZEXEL

106672-3250

1066723250

HINO

220004982A

220004982a

Rating:

Cross reference number

ZEXEL

106672-3250

1066723250

HINO

220004982A

220004982a

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve (drive side)

134424-1420

Overflow valve opening pressure (drive side)

kPa

162

147

177

Overflow valve opening pressure (drive side)

kgf/cm2

1.65

1.5

1.8

Overflow valve (governor side)

134424-1720

Overflow valve opening pressure (governor side)

kPa

162

147

177

Overflow valve opening pressure (governor side)

kgf/cm2

1.65

1.5

1.8

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

4.5

4.44

4.5

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.75 60.25

Cal 1-4 deg. 60 59.75 60.25

Difference between angles 2

Cyl.1-2 deg. 120 119.75 120.25

Cyl.1-2 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cal 1-3 deg. 240 239.75 240.25

Cal 1-3 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-5 deg. 300 299.75 300.25

Cal 1-5 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

A

Rack position

8.8

Pump speed

r/min

650

650

650

Average injection quantity

mm3/st.

173

171

175

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Boost pressure

kPa

39.3

39.3

Boost pressure

mmHg

295

295

Injection quantity adjustment_02

Adjusting point

B

Rack position

9.1

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

183.5

180.5

186.5

Max. variation between cylinders

%

0

-5

5

Fixing the lever

*

Boost pressure

kPa

39.3

39.3

Boost pressure

mmHg

295

295

Injection quantity adjustment_03

Adjusting point

C

Rack position

8.8

Pump speed

r/min

850

850

850

Average injection quantity

mm3/st.

171

165

177

Fixing the lever

*

Boost pressure

kPa

39.3

39.3

Boost pressure

mmHg

295

295

Injection quantity adjustment_04

Adjusting point

D

Rack position

8.4

Pump speed

r/min

1050

1050

1050

Average injection quantity

mm3/st.

160.5

157.5

163.5

Max. variation between cylinders

%

0

-5

5

Fixing the lever

*

Boost pressure

kPa

39.3

39.3

Boost pressure

mmHg

295

295

Injection quantity adjustment_05

Adjusting point

E

Rack position

7.4

Pump speed

r/min

1150

1150

1150

Average injection quantity

mm3/st.

137

132

142

Fixing the lever

*

Boost pressure

kPa

39.3

39.3

Boost pressure

mmHg

295

295

Injection quantity adjustment_06

Adjusting point

F

Rack position

9.2+0.2

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

186

180

192

Fixing the lever

*

Boost pressure

kPa

39.3

39.3

Boost pressure

mmHg

295

295

Rack limit

*

Injection quantity adjustment_07

Adjusting point

G

Rack position

6.4

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

86

84

88

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_08

Adjusting point

I

Rack position

4.6+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

11

8

14

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

650

650

650

Rack position

6.4

Boost pressure

kPa

9.3

9.3

11.3

Boost pressure

mmHg

70

70

85

Boost compensator adjustment_02

Pump speed

r/min

650

650

650

Rack position

8.8

Boost pressure

kPa

26

26

26

Boost pressure

mmHg

195

195

195

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Lever ratio: RT

(2)Target shim dimension: TH

(3)RACK LIMIT: RAL

(4)Set idle at delivery

(5)Damper spring setting: DL

----------

RT=0.8 TH=1.5mm RAL=9.2+0.2mm DL=3.6-0.2mm

----------

----------

RT=0.8 TH=1.5mm RAL=9.2+0.2mm DL=3.6-0.2mm

----------

Speed control lever angle

F:Full speed

----------

----------

a=8deg+-5deg

----------

----------

a=8deg+-5deg

0000000901

F:Full load

I:Idle

(1)Set point I

(2)At delivery

----------

----------

a=25deg+-5deg b=45deg+-3deg c=47deg+-5deg

----------

----------

a=25deg+-5deg b=45deg+-3deg c=47deg+-5deg

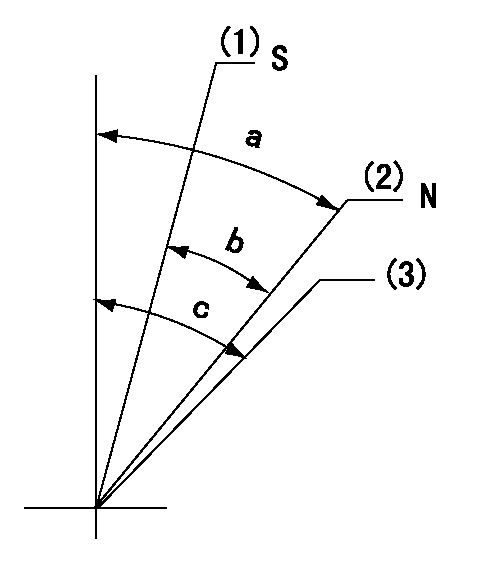

Stop lever angle

N:Engine manufacturer's normal use

S:Stop the pump.

(1)Rack position = aa, stopper bolt setting

(2)Rack position bb

(3)Free (at delivery)

----------

aa=2.5-0.5mm bb=12mm

----------

a=40deg+-5deg b=30deg+-5deg c=(50deg)

----------

aa=2.5-0.5mm bb=12mm

----------

a=40deg+-5deg b=30deg+-5deg c=(50deg)

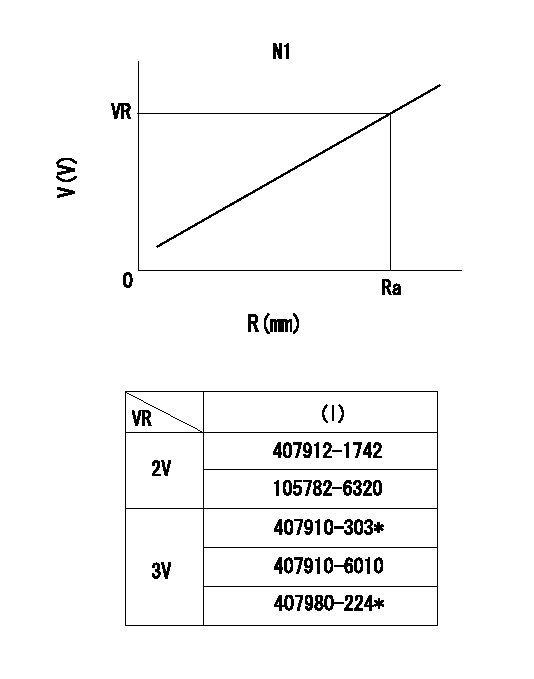

0000001501 RACK SENSOR

R:Rack position (mm)

V:Voltage (V)

After installing the rack sensor, confirm the output value (VR).

----------

N1=650r/min Ra=8.8mm VR=1.7+-0.1V

----------

----------

N1=650r/min Ra=8.8mm VR=1.7+-0.1V

----------

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(0deg)

----------

----------

a=(0deg)

Information:

General Information

Learn principles of operation of engines from "Basic Engine" in Fundamentals of Service Manual 30 - ENGINES.Design Characteristics

The 3-164D, 3-179D, 4-219D, 4-239D, 4-276D, 6-329D, 6-359D, and 6-414D engines have:1. Internal combustion2. Four strokes per cycle3. In-line type cylinder block4. Diesel fueling5. Valves in cylinder head6. Natural aspiration7. Liquid coolant8. Pressure lubricationThe 4-239T, 4-276T, 6-359T, and 6-414T engines have:1. Internal combustion2. Four strokes per cycle3. In-line type cylinder block4. Diesel fueling5. Valves in cylinder head6. Turbocharger7. Liquid coolant8. Pressure lubricationFront Reference

Fig. 1-Water PumpThe water pump (Fig. 1) end is the "front" of the engine.Direction of Crankshaft Rotation

Fig. 2-Crankshaft RotationThe crankshaft turns clockwise when viewed from the water pump end.Firing Order

Fig. 3-Cylinder Arrangement3-164 and 3-179 EngineFiring order is: 1-2-3

Fig. 4-Cylinder Arrangement4-219, 4-239, and 4-276 EnginesFiring order is: 1-3-4-2

Fig. 5-Cylinder Arrangement6-329, 6-359, and 6-414 EnginesFiring order is: 1-5-3-6-2-4

Learn principles of operation of engines from "Basic Engine" in Fundamentals of Service Manual 30 - ENGINES.Design Characteristics

The 3-164D, 3-179D, 4-219D, 4-239D, 4-276D, 6-329D, 6-359D, and 6-414D engines have:1. Internal combustion2. Four strokes per cycle3. In-line type cylinder block4. Diesel fueling5. Valves in cylinder head6. Natural aspiration7. Liquid coolant8. Pressure lubricationThe 4-239T, 4-276T, 6-359T, and 6-414T engines have:1. Internal combustion2. Four strokes per cycle3. In-line type cylinder block4. Diesel fueling5. Valves in cylinder head6. Turbocharger7. Liquid coolant8. Pressure lubricationFront Reference

Fig. 1-Water PumpThe water pump (Fig. 1) end is the "front" of the engine.Direction of Crankshaft Rotation

Fig. 2-Crankshaft RotationThe crankshaft turns clockwise when viewed from the water pump end.Firing Order

Fig. 3-Cylinder Arrangement3-164 and 3-179 EngineFiring order is: 1-2-3

Fig. 4-Cylinder Arrangement4-219, 4-239, and 4-276 EnginesFiring order is: 1-3-4-2

Fig. 5-Cylinder Arrangement6-329, 6-359, and 6-414 EnginesFiring order is: 1-5-3-6-2-4