Information injection-pump assembly

ZEXEL

106671-9820

1066719820

Rating:

Service parts 106671-9820 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

10.

NOZZLE AND HOLDER ASSY

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

13.

NOZZLE-HOLDER

14.

NOZZLE

15.

NOZZLE SET

Include in #1:

106671-9820

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

106671-9820

1066719820

Zexel num

Bosch num

Firm num

Name

106671-9820

DPICO

INJECTION-PUMP ASSEMBLY

6D22 * Q

6D22 * Q

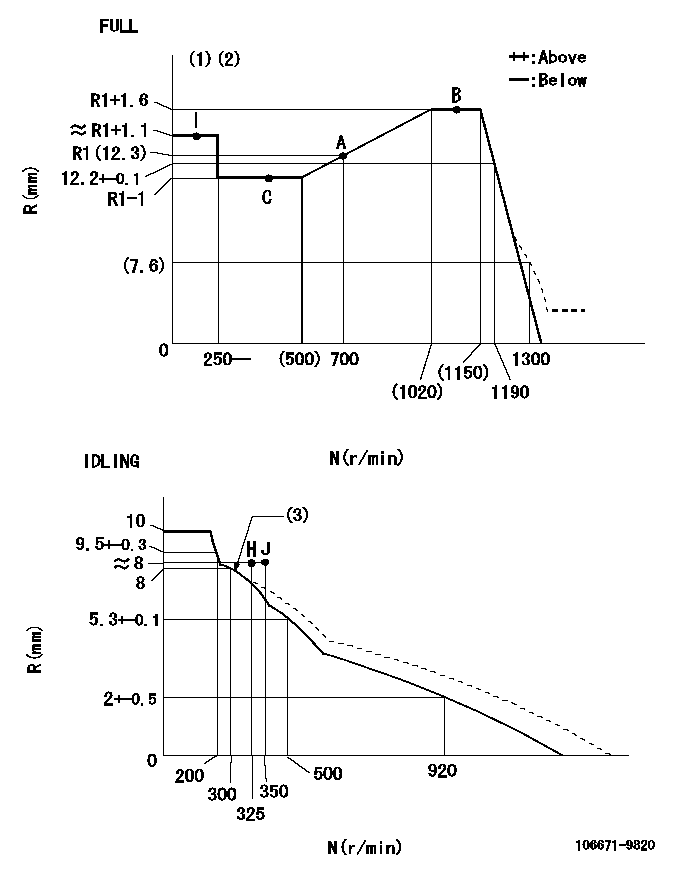

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8250

Bosch type code

1 688 901 101

Nozzle

105780-0120

Bosch type code

1 688 901 990

Nozzle holder

105780-2190

Opening pressure

MPa

20.7

Opening pressure

kgf/cm2

211

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131425-0220

Overflow valve opening pressure

kPa

157

157

157

Overflow valve opening pressure

kgf/cm2

1.6

1.6

1.6

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.9

3.85

3.95

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

12.3

Pump speed

r/min

700

700

700

Each cylinder's injection qty

mm3/st.

129

125.8

132.2

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

Z

Rack position

8+-0.5

Pump speed

r/min

570

570

570

Each cylinder's injection qty

mm3/st.

15

13

17

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(12.3)

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

129

128

130

Basic

*

Fixing the lever

*

Timer adjustment

Pump speed

r/min

750--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

-

Advance angle

deg.

1.5

1

2

Remarks

Measure the actual speed.

Measure the actual speed.

Timer adjustment_03

Pump speed

r/min

-

Advance angle

deg.

0

0

0

Remarks

Measure the actual speed.

Measure the actual speed.

Timer adjustment_04

Pump speed

r/min

700

Advance angle

deg.

0.5

Timer adjustment_05

Pump speed

r/min

1100

Advance angle

deg.

3.5

3

4

Timer adjustment_06

Pump speed

r/min

-

Advance angle

deg.

4

3.5

4.5

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Damper spring setting: DL

----------

T1=AG11 DL=7.9-0.2mm

----------

----------

T1=AG11 DL=7.9-0.2mm

----------

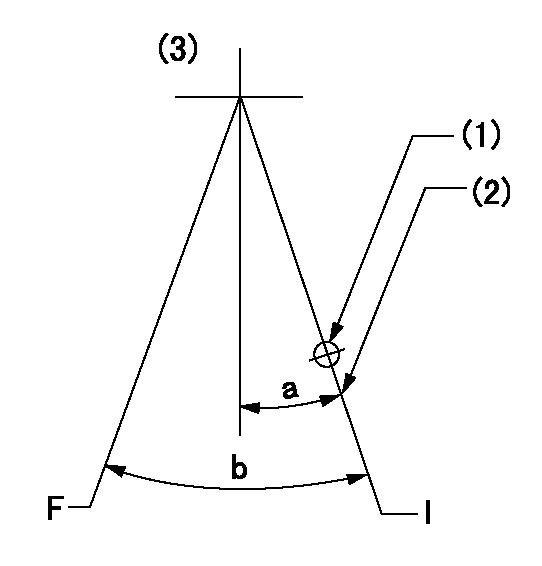

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt setting

(3)Viewed from feed pump side.

----------

aa=37.5mm

----------

a=0deg+-5deg b=(33deg)+-3deg

----------

aa=37.5mm

----------

a=0deg+-5deg b=(33deg)+-3deg

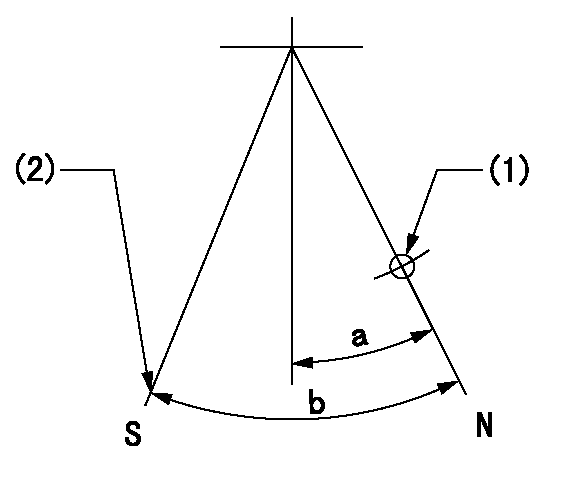

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the hole at R = aa

(2)Set the stopper bolt so that speed = bb and rack position = cc. (Confirm non-injection.)

----------

aa=45mm bb=1100r/min cc=3.5+-0.3mm

----------

a=29.5deg+-5deg b=40deg+-5deg

----------

aa=45mm bb=1100r/min cc=3.5+-0.3mm

----------

a=29.5deg+-5deg b=40deg+-5deg

0000001501 MICRO SWITCH

Adjustment of the micro-switch

Adjust the bolt to obtain the following lever position when the micro-switch is ON.

(1)Speed N1

(2)Rack position Ra

----------

N1=475r/min Ra=7.6+-0.1mm

----------

----------

N1=475r/min Ra=7.6+-0.1mm

----------

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=11deg

----------

a=(5deg)

----------

aa=11deg

----------

a=(5deg)

Information:

Illustration 3 g06519715

DOC brackets

Illustration 4 g06519717

DOC

Connect the welding ground cable directly to the DOC brackets or the DOC that will be welded. Place the ground cable as close as possible to the weld. This location will reduce the possibility of welding current damage bearings, hydraulic components, electrical components, and ground straps.Note: If electrical components are used as a ground for the welder, current flow from the welder could severely damage the component. Current flow from the welder could also severely damage electrical components that are located between the welder ground and the weld.

Illustration 5 g06519270

Weld blanket

Illustration 6 g06519272

Use a weld blanket draped over the engine to protect the engine from weld splatter. Likely need 2 or 3 blankets to cover between DOCs and the entire engine from splatter.

Illustration 7 g06519274

Illustration 8 g06519277

(1) 536-5400 Plate

Clean the top surface in the two locations where plates (1) will be welded in place with either a wire wheel or a flap disk.Note: Failure to clean the weld area could result in poor weld quality.

Illustration 9 g06519323

(D1) 6 2 mm (0.236 0.079 inch)

Illustration 10 g06519297

(D1) 6 2 mm (0.236 0.079 inch)

(D2) 43 3 mm (1.693 0.118 inch)

Illustration 11 g06519348

(D2) 43 3 mm (1.693 0.118 inch)

Set the plates on the top side of the housing and line up perpendicular to the front face. Position the plates to dimension (D1) from the front edge of the top plate.

Position the plates to dimension (D2) from the far edge of the rounded plate. There is a chamfer and fillet weld that will make measurements less precise. Use a tape measure to position.Note: Etching marks may also be present on the top of the unit and can be used for further positional guidance.

Illustration 12 g06519373

(W1) Tack weld

With the plates in place, add tack welds (W1) to the plates shown in Illustration 12. Use 308L weld wire.

Illustration 13 g06519408

(W2) 50 to 100 mm (1.969 to 3.937 inch)

Skip fillet weld (W2) down the side of each plate and then weld at the ends of each plates. Use 308L weld wire.

Illustration 14 g06519430

Finished product

Verify the weld quality and look for the following:

Cracks

Porosity

Inclusions

Convexity/Excess Weld Material

Concavity/Under Fill

Excess Penetration

Lack of Penetration

Fillet Weld - Undersize

Lack of Fusion

Undercut

Toe Radius

Overlap

Poor Restarts/Tie-ins

Cleaning/Grinding

Spatter/Arc Strike/Wire Stub

Illustration 15 g06519435

Mark the new plates with "THIS SIDE UP".Note: Make sure that the text is visible and stands out on the DOC.

Have questions with 106671-9820?

Group cross 106671-9820 ZEXEL

Dpico

106671-9820

INJECTION-PUMP ASSEMBLY

6D22

6D22