Information injection-pump assembly

BOSCH

F 019 Z20 089

f019z20089

ZEXEL

106671-9571

1066719571

Rating:

Cross reference number

BOSCH

F 019 Z20 089

f019z20089

ZEXEL

106671-9571

1066719571

Zexel num

Bosch num

Firm num

Name

106671-9571

F 019 Z20 089

DPICO

INJECTION-PUMP ASSEMBLY

Q Q

Q Q

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-4420

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.4

4.35

4.45

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

12.3

Pump speed

r/min

700

700

700

Each cylinder's injection qty

mm3/st.

154

150.1

157.9

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

R2(5.5)

Pump speed

r/min

325

325

325

Each cylinder's injection qty

mm3/st.

11

9.4

12.6

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(12.3)

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

154

153

155

Basic

*

Fixing the lever

*

Boost pressure

kPa

84

84

Boost pressure

mmHg

630

630

Injection quantity adjustment_04

Adjusting point

G

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

110

90

130

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

550

550

550

Rack position

(R3-2.5)

Boost pressure

kPa

6.7

5.4

8

Boost pressure

mmHg

50

40

60

Boost compensator adjustment_02

Pump speed

r/min

550

550

550

Rack position

R3-0.8

Boost pressure

kPa

45.3

44.6

46

Boost pressure

mmHg

340

335

345

Boost compensator adjustment_03

Pump speed

r/min

550

550

550

Rack position

R3(R1(12

.3))

Boost pressure

kPa

70.6

67.3

73.9

Boost pressure

mmHg

530

505

555

Timer adjustment

Pump speed

r/min

-

Advance angle

deg.

1.5

1

2

Load

0/4

Remarks

Measure speed (beginning of operation).

Measure speed (beginning of operation).

Timer adjustment_02

Pump speed

r/min

-

Advance angle

deg.

0

0

0

Load

0/4

Remarks

Measure the actual speed.

Measure the actual speed.

Timer adjustment_03

Pump speed

r/min

-

Advance angle

deg.

0

0

0

Load

4/4

Remarks

Measure the actual speed.

Measure the actual speed.

Timer adjustment_04

Pump speed

r/min

-

Advance angle

deg.

3.5

2.8

4

Load

4/4

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

Test data Ex:

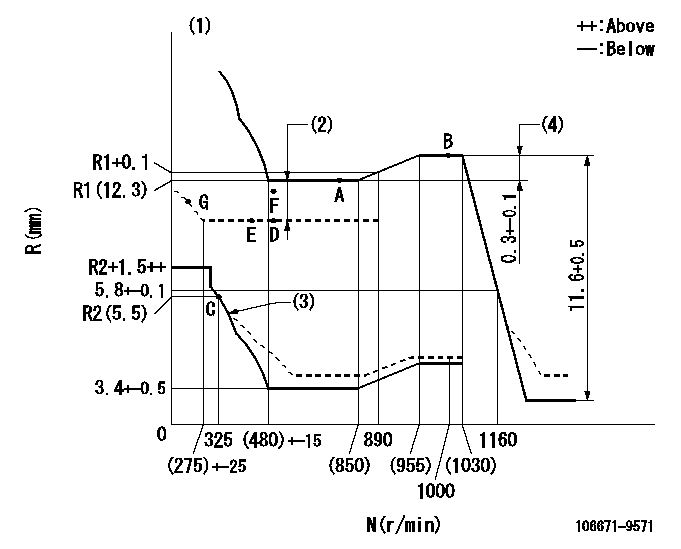

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Tolerance for racks not indicated: +-0.05mm.

(2)Boost compensator stroke: BCL

(3)Damper spring setting: DL

(4)Rack difference between N = N1 and N = N2

----------

BCL=(2.5)+-0.1mm DL=(R2-0.2)-0.2mm N1=1000r/min N2=700r/min

----------

----------

BCL=(2.5)+-0.1mm DL=(R2-0.2)-0.2mm N1=1000r/min N2=700r/min

----------

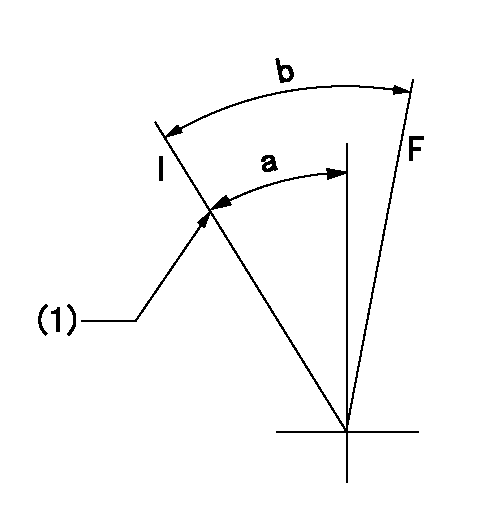

Speed control lever angle

F:Full speed

----------

----------

a=(17.5deg)+-5deg

----------

----------

a=(17.5deg)+-5deg

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=21deg+-5deg b=33deg+-3deg

----------

----------

a=21deg+-5deg b=33deg+-3deg

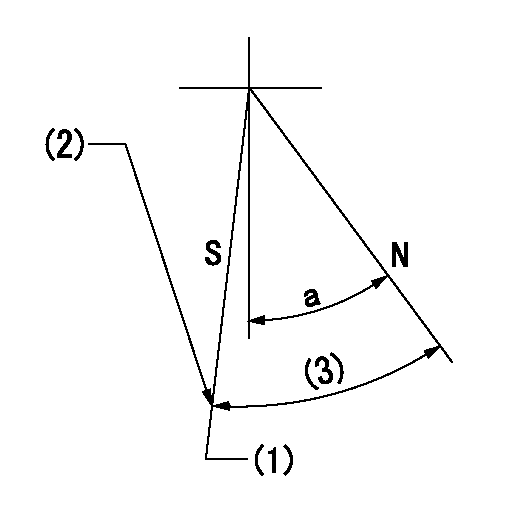

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = actual measurement

(2)Stopper bolt setting

(3)(Actual measurement)

----------

----------

a=38deg+-5deg

----------

----------

a=38deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(6deg)

----------

----------

a=(6deg)

Information:

Introduction

The problem that is identified below has a known solution. Use the solution that is identified below.Problem

The procedure for the Disassembly and Assembly needs to be updated to include the information below.Solution

Do not operate or work on this product unless you have read and understood the instruction and warnings in the relevant Operation and Maintenance Manuals and relevant service literature. Failure to follow the instructions or heed the warnings could result in injury or death. Proper care is your responsibility.

Inspect the quill tubes and fuel injectors for cuts or marks at the mating surfaces.

Replace any quill tubes since the quill tubes are a one time use component. Replace the copper washer when replacing the fuel injector.

Follow the steps below for installing the quill tunes and fuel injectors.

Seat the injector by installing and torquing the injector hold down clamp bolt to 30 3 N m (22 2 lb ft).

Install the quill tube and tighten the quill nut between 15 N m (11 lb ft) to 20 N m (15 lb ft).

Apply a final torque of 30 3 N m (22 2 lb ft) to the injector hold down clamp bolt.

Apply a final torque between 50 N m (37 lb ft) to 55 N m (41 lb ft).

The problem that is identified below has a known solution. Use the solution that is identified below.Problem

The procedure for the Disassembly and Assembly needs to be updated to include the information below.Solution

Do not operate or work on this product unless you have read and understood the instruction and warnings in the relevant Operation and Maintenance Manuals and relevant service literature. Failure to follow the instructions or heed the warnings could result in injury or death. Proper care is your responsibility.

Inspect the quill tubes and fuel injectors for cuts or marks at the mating surfaces.

Replace any quill tubes since the quill tubes are a one time use component. Replace the copper washer when replacing the fuel injector.

Follow the steps below for installing the quill tunes and fuel injectors.

Seat the injector by installing and torquing the injector hold down clamp bolt to 30 3 N m (22 2 lb ft).

Install the quill tube and tighten the quill nut between 15 N m (11 lb ft) to 20 N m (15 lb ft).

Apply a final torque of 30 3 N m (22 2 lb ft) to the injector hold down clamp bolt.

Apply a final torque between 50 N m (37 lb ft) to 55 N m (41 lb ft).

Have questions with 106671-9571?

Group cross 106671-9571 ZEXEL

Niigata-Urawa

Dpico

Komatsu

Mitsubishi-Heav

Dpico

106671-9571

F 019 Z20 089

INJECTION-PUMP ASSEMBLY

Q

Q