Information injection-pump assembly

BOSCH

9 400 617 050

9400617050

ZEXEL

106671-9480

1066719480

Rating:

Service parts 106671-9480 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

10.

NOZZLE AND HOLDER ASSY

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

13.

NOZZLE-HOLDER

14.

NOZZLE

15.

NOZZLE SET

Include in #1:

106671-9480

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 617 050

9400617050

ZEXEL

106671-9480

1066719480

Zexel num

Bosch num

Firm num

Name

106671-9480

9 400 617 050

CHINA

INJECTION-PUMP ASSEMBLY

6130T K

6130T K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-1520

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.65

3.6

3.7

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

10.1

Pump speed

r/min

1050

1050

1050

Average injection quantity

mm3/st.

150

147

153

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Boost pressure

kPa

48

48

Boost pressure

mmHg

360

360

Injection quantity adjustment_02

Adjusting point

C

Rack position

6.3+-0.5

Pump speed

r/min

280

280

280

Average injection quantity

mm3/st.

17.5

15.5

19.5

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_03

Adjusting point

D

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

155

115

195

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

500

500

500

Rack position

R1-1

Boost pressure

kPa

16

14.7

17.3

Boost pressure

mmHg

120

110

130

Boost compensator adjustment_02

Pump speed

r/min

500

500

500

Rack position

R1(10.1)

Boost pressure

kPa

34.7

28

41.4

Boost pressure

mmHg

260

210

310

Timer adjustment

Pump speed

r/min

550--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

500

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

800

Advance angle

deg.

2.2

1.7

2.7

Timer adjustment_04

Pump speed

r/min

1050

Advance angle

deg.

5

4.5

5.5

Remarks

Finish

Finish

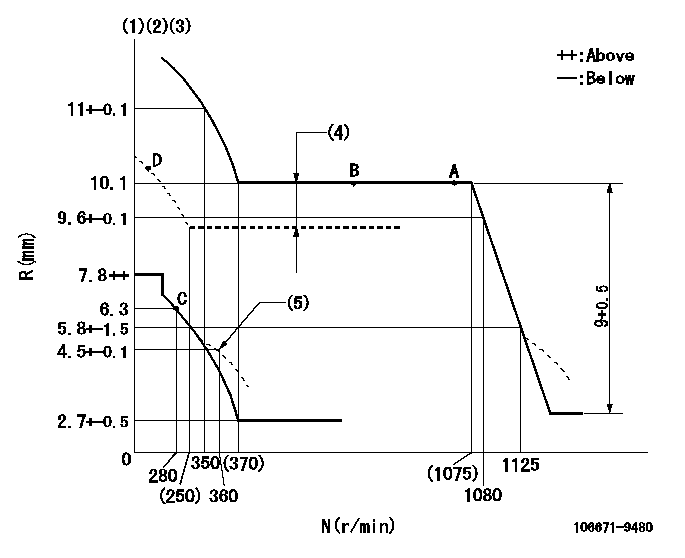

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Lever ratio: RT

(2)Target shim dimension: TH

(3)Tolerance for racks not indicated: +-0.05mm.

(4)Boost compensator stroke: BCL

(5)Damper spring setting

----------

RT=1 TH=2.1mm BCL=1+-0.1mm

----------

----------

RT=1 TH=2.1mm BCL=1+-0.1mm

----------

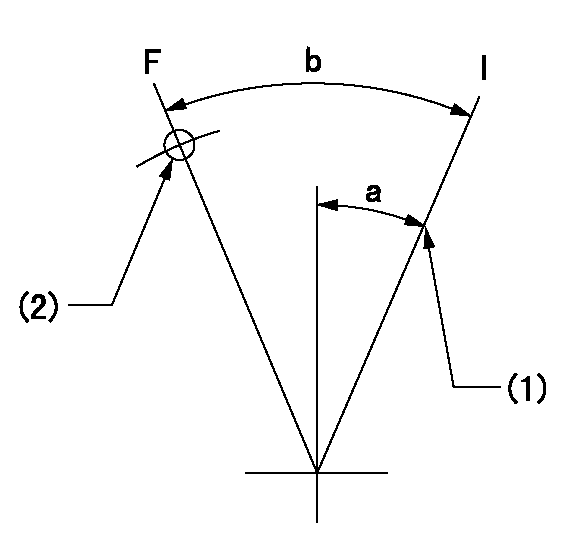

Speed control lever angle

F:Full speed

----------

----------

a=(10deg)+-5deg

----------

----------

a=(10deg)+-5deg

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

(2)Use the hole at R = aa

----------

aa=55mm

----------

a=15deg+-5deg b=28deg+-3deg

----------

aa=55mm

----------

a=15deg+-5deg b=28deg+-3deg

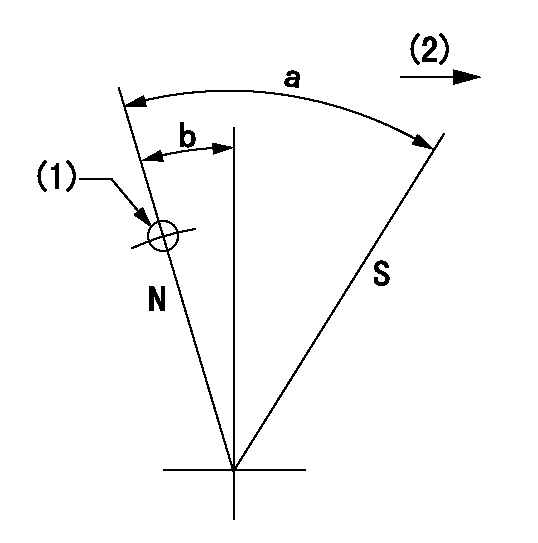

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the hole at R = aa

(2)Drive side

----------

aa=30mm

----------

a=64deg+-5deg b=25deg+-5deg

----------

aa=30mm

----------

a=64deg+-5deg b=25deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(50deg)

----------

----------

a=(50deg)

Information:

Lubricate, Oil - To apply a material to a surface to reduce

Pry - To raise, move or open with a lever.

Remove - To take off.

Route - To install a harness, hose, or wire along a specific course or layout along or through a product, to direct along a predefined path.

Special Tool - To work with a nonstandard device.

Tighten - To make nearer to fully stretched, without slack, to apply tension or torque.Torque Specifications

Refer to Torque Specifications, SENR3130 for the most up-to-date torque specifications for standard fasteners.Tooling Required

The table below contains the tooling needed for this procedure.

Table 39

Item Qty Part Number Part Name Illustration (Substep) Location

T1 1 5F-4764 Pry Bar Illustration 6 (1) Fuel Injector Removal

Illustration 2 g06285426

Illustration 3 g06285429

Illustration 4 g06285477

Illustration 5 g06285492

Illustration 6 g06285497Fuel Injector Installation

Illustration 7 g06285503

Illustration 8 g06285515

Illustration 9 g06285527

Illustration 10 g06285536

Refer to the appropriate Testing and Adjusting manual to check or reset the engine valve lash.

Illustration 11 g06285542Reference Section

Pry - To raise, move or open with a lever.

Remove - To take off.

Route - To install a harness, hose, or wire along a specific course or layout along or through a product, to direct along a predefined path.

Special Tool - To work with a nonstandard device.

Tighten - To make nearer to fully stretched, without slack, to apply tension or torque.Torque Specifications

Refer to Torque Specifications, SENR3130 for the most up-to-date torque specifications for standard fasteners.Tooling Required

The table below contains the tooling needed for this procedure.

Table 39

Item Qty Part Number Part Name Illustration (Substep) Location

T1 1 5F-4764 Pry Bar Illustration 6 (1) Fuel Injector Removal

Illustration 2 g06285426

Illustration 3 g06285429

Illustration 4 g06285477

Illustration 5 g06285492

Illustration 6 g06285497Fuel Injector Installation

Illustration 7 g06285503

Illustration 8 g06285515

Illustration 9 g06285527

Illustration 10 g06285536

Refer to the appropriate Testing and Adjusting manual to check or reset the engine valve lash.

Illustration 11 g06285542Reference Section

Have questions with 106671-9480?

Group cross 106671-9480 ZEXEL

Niigata-Urawa

Dpico

Komatsu

Mitsubishi-Heav

Dpico

China

106671-9480

9 400 617 050

INJECTION-PUMP ASSEMBLY

6130T

6130T