Information injection-pump assembly

ZEXEL

106671-9460

1066719460

Rating:

Cross reference number

ZEXEL

106671-9460

1066719460

Zexel num

Bosch num

Firm num

Name

106671-9460

DPICO

INJECTION-PUMP ASSEMBLY

DE12NA * Q

DE12NA * Q

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-4420

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.7

4.65

4.75

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

13.2

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

121.5

118.5

124.5

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

8.5+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

11

9.5

12.5

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(13.2)

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

121.5

119.5

123.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+0.3

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

121.5

115.5

127.5

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

C

Rack position

R1-0.4

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

110

104

116

Fixing the lever

*

Injection quantity adjustment_06

Adjusting point

I

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

95

85

105

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

(N1+50)-

-

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

N1

Advance angle

deg.

0.5

Remarks

Measure the actual speed.

Measure the actual speed.

Timer adjustment_03

Pump speed

r/min

-

Advance angle

deg.

5.5

5

6

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

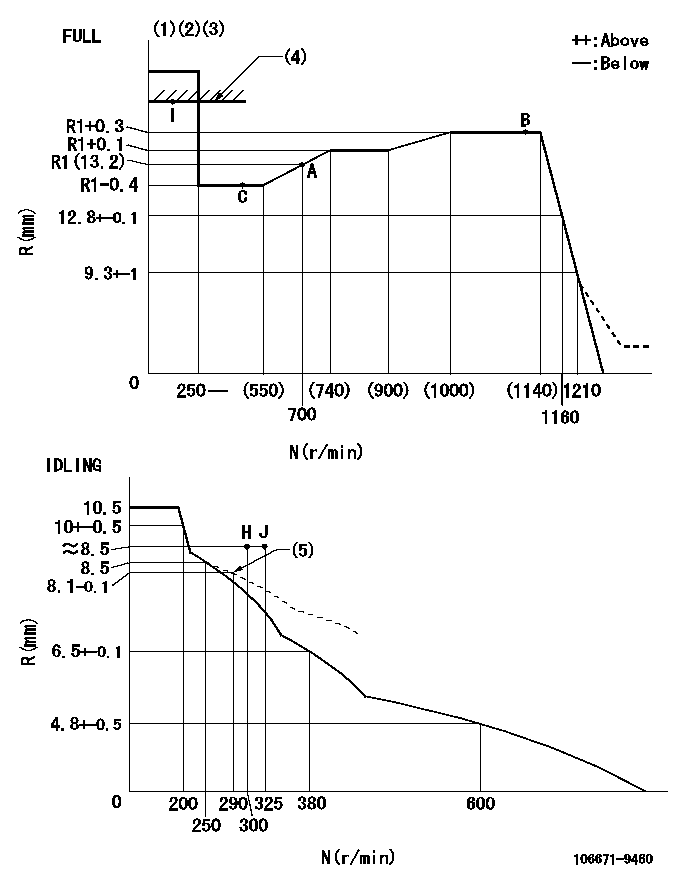

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Microswitch adjustment unnecessary.

(4)RACK LIMIT

(5)Damper spring setting

----------

T1=AE19

----------

----------

T1=AE19

----------

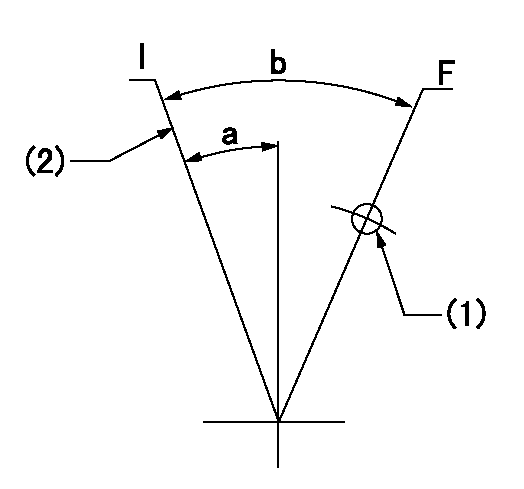

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt set position 'H'

----------

aa=70mm

----------

a=14deg+-5deg b=(35deg)+-3deg

----------

aa=70mm

----------

a=14deg+-5deg b=(35deg)+-3deg

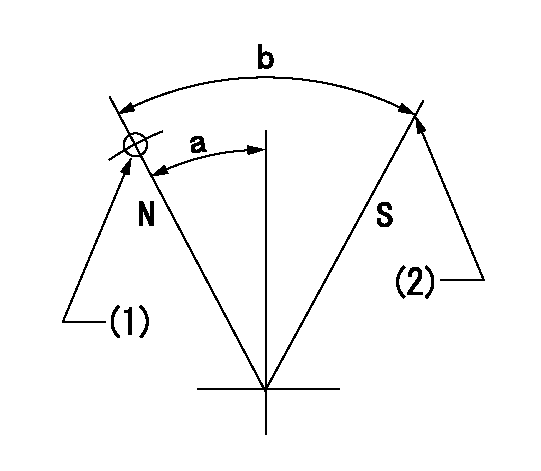

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the hole at R = aa

(2)Set stopper screw so that rack position = bb (after setting apply red paint).

----------

aa=40mm bb=1.5+-0.3mm

----------

a=20deg+-5deg b=44deg+-5deg

----------

aa=40mm bb=1.5+-0.3mm

----------

a=20deg+-5deg b=44deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=10deg

----------

a=(70deg)

----------

aa=10deg

----------

a=(70deg)

Information:

Reassemble Motor to Pump

Thoroughly clean the motor shaft and the hollow pump shaft. Remove the tape from the key (5) and keyway.

Apply a liberal amount of Loctite Nickel Anti-Seize No. 77164 to the pump shaft.

Install the shaft key (5) into the keyway.

Slide the motor shaft into the hollow pump shaft.

Reinstall the four washers (2) and nuts (1).Primary Strainer Removal and Installation

Primary Strainer Removal

Illustration 34 g06272994

(1) Primary Strainer

(2) Drain Plug

(3) Nut

(4) Strainer Cover

(5) Compression Ring

(6) Seal

(7) Strainer Housing

(8) Strainer Screens

Place a suitable drain pan underneath the primary strainer (1) to capture DEF fluid.

Remove and store the drain plug (2) from the bottom of the strainer cover (4). Allow DEF fluid to drain.

Inspect drain plug (1) and any seals, replace if damaged.

Install drain plug (2) into the bottom of the strainer cover (4).

Remove and store eight nuts (3) and the compression flange (5) located around the bottom of the strainer cover (4).

Remove and store the strainer cover (4) of the primary strainer (1).

Remove and inspect seal (6), replace if damaged.

Remove and discard the primary strainer screens (8) from the screen housing (7).Primary Strainer Installation

Install new primary strainer screens (8) into the screen housing (7).

Install screen housing (7) into the primary strainer (1).

Install the seal (6) onto the bottom of the strainer cover (4).

Install the strainer cover (4), compression flange (5), and eight nuts (3).

Open primary valve, operate DEF Transfer Pump and check for leaks around the bottom of the primary strainer (1).

Remove drain pan and dispose of DEF fluid.Secondary Strainer Removal and Installation

Secondary Strainer Removal

Illustration 35 g06272975

(1) Secondary Strainer

(2) Strainer Element

(3) Seal

(4) Strainer Cover

(5) Bolt

Place a suitable drain pan underneath the secondary strainer (1) to capture DEF fluid.

Remove and store the bolts (5).

Remove and store strainer cover (4).

Remove and inspect seal (3), replace if damaged.

Remove and discard strainer element (2).Secondary Strainer Installation

Install new secondary strainer element (2) into the secondary strainer (1).

Install the seal (3) onto the bottom of the strainer cover (4).

Install the strainer cover (4) with bolts (5).

Open secondary valve, operate DEF Transfer Pump and check for leaks around the bottom of the secondary strainer (1).

Remove drain pan and dispose of DEF fluid.Product Description

Extended Warranties and Service Contracts

A wide variety of protection plans are available for Cat Engines. Consult your Caterpillardealer for detailed information on the specific programs and coverages that are available.DEF Transfer Pump is an optional attachment to an engine system. Refer to the warranty information for your engine or consult your Caterpillar dealer.Customer Assistance

USA and Canada

When a problem arises concerning the operation or the service of a Marine engine, the problem will normally be managed by the dealer in your area.Your satisfaction is a primary concern to Caterpillar and to Caterpillar dealers. If you have a problem that has not been handled to your complete satisfaction, follow these steps:

Discuss your problem with a manager from the dealership.

If your problem cannot be resolved at the dealer level, use the phone number that is listed below to talk with a Field Service Coordinator:877-228-9900

The normal hours are from 7:00 AM

Thoroughly clean the motor shaft and the hollow pump shaft. Remove the tape from the key (5) and keyway.

Apply a liberal amount of Loctite Nickel Anti-Seize No. 77164 to the pump shaft.

Install the shaft key (5) into the keyway.

Slide the motor shaft into the hollow pump shaft.

Reinstall the four washers (2) and nuts (1).Primary Strainer Removal and Installation

Primary Strainer Removal

Illustration 34 g06272994

(1) Primary Strainer

(2) Drain Plug

(3) Nut

(4) Strainer Cover

(5) Compression Ring

(6) Seal

(7) Strainer Housing

(8) Strainer Screens

Place a suitable drain pan underneath the primary strainer (1) to capture DEF fluid.

Remove and store the drain plug (2) from the bottom of the strainer cover (4). Allow DEF fluid to drain.

Inspect drain plug (1) and any seals, replace if damaged.

Install drain plug (2) into the bottom of the strainer cover (4).

Remove and store eight nuts (3) and the compression flange (5) located around the bottom of the strainer cover (4).

Remove and store the strainer cover (4) of the primary strainer (1).

Remove and inspect seal (6), replace if damaged.

Remove and discard the primary strainer screens (8) from the screen housing (7).Primary Strainer Installation

Install new primary strainer screens (8) into the screen housing (7).

Install screen housing (7) into the primary strainer (1).

Install the seal (6) onto the bottom of the strainer cover (4).

Install the strainer cover (4), compression flange (5), and eight nuts (3).

Open primary valve, operate DEF Transfer Pump and check for leaks around the bottom of the primary strainer (1).

Remove drain pan and dispose of DEF fluid.Secondary Strainer Removal and Installation

Secondary Strainer Removal

Illustration 35 g06272975

(1) Secondary Strainer

(2) Strainer Element

(3) Seal

(4) Strainer Cover

(5) Bolt

Place a suitable drain pan underneath the secondary strainer (1) to capture DEF fluid.

Remove and store the bolts (5).

Remove and store strainer cover (4).

Remove and inspect seal (3), replace if damaged.

Remove and discard strainer element (2).Secondary Strainer Installation

Install new secondary strainer element (2) into the secondary strainer (1).

Install the seal (3) onto the bottom of the strainer cover (4).

Install the strainer cover (4) with bolts (5).

Open secondary valve, operate DEF Transfer Pump and check for leaks around the bottom of the secondary strainer (1).

Remove drain pan and dispose of DEF fluid.Product Description

Extended Warranties and Service Contracts

A wide variety of protection plans are available for Cat Engines. Consult your Caterpillardealer for detailed information on the specific programs and coverages that are available.DEF Transfer Pump is an optional attachment to an engine system. Refer to the warranty information for your engine or consult your Caterpillar dealer.Customer Assistance

USA and Canada

When a problem arises concerning the operation or the service of a Marine engine, the problem will normally be managed by the dealer in your area.Your satisfaction is a primary concern to Caterpillar and to Caterpillar dealers. If you have a problem that has not been handled to your complete satisfaction, follow these steps:

Discuss your problem with a manager from the dealership.

If your problem cannot be resolved at the dealer level, use the phone number that is listed below to talk with a Field Service Coordinator:877-228-9900

The normal hours are from 7:00 AM

Have questions with 106671-9460?

Group cross 106671-9460 ZEXEL

Niigata-Urawa

Dpico

Komatsu

Mitsubishi-Heav

Dpico

106671-9460

INJECTION-PUMP ASSEMBLY

DE12NA

DE12NA