Information injection-pump assembly

BOSCH

F 019 Z20 084

f019z20084

ZEXEL

106671-9430

1066719430

Rating:

Service parts 106671-9430 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

15.7(160)/21.6(220)

15.

NOZZLE SET

Include in #1:

106671-9430

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

F 019 Z20 084

f019z20084

ZEXEL

106671-9430

1066719430

Zexel num

Bosch num

Firm num

Name

106671-9430

F 019 Z20 084

DPICO

INJECTION-PUMP ASSEMBLY

DE12TI Q

DE12TI Q

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-4420

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.2

4.15

4.25

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

9.9

Pump speed

r/min

1050

1050

1050

Average injection quantity

mm3/st.

166

164

168

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Boost pressure

kPa

80

80

Boost pressure

mmHg

600

600

Injection quantity adjustment_02

Adjusting point

B

Rack position

4.8+-0.5

Pump speed

r/min

250

250

250

Average injection quantity

mm3/st.

9

7.5

10.5

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_03

Adjusting point

C

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

105

105

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

500

500

500

Rack position

7.9

Boost pressure

kPa

13.3

11.3

15.3

Boost pressure

mmHg

100

85

115

Boost compensator adjustment_02

Pump speed

r/min

500

500

500

Rack position

10.4

Boost pressure

kPa

66.7

66.7

66.7

Boost pressure

mmHg

500

500

500

Timer adjustment

Pump speed

r/min

750--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

700

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1100

Advance angle

deg.

3

2.5

3.5

Remarks

Finish

Finish

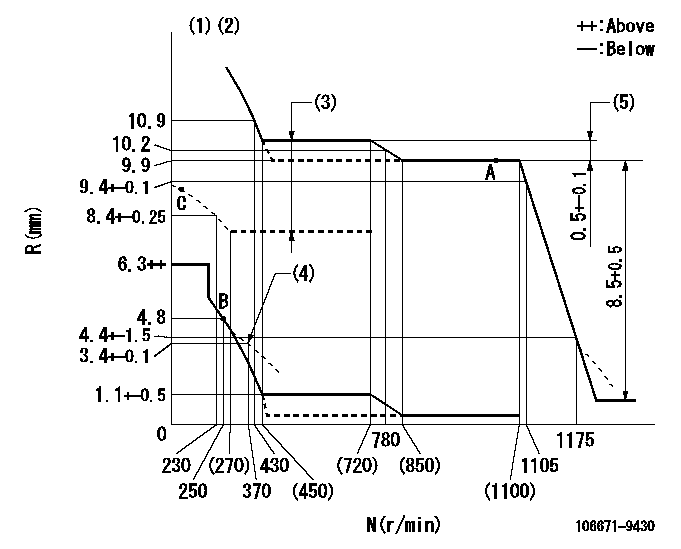

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Tolerance for racks not indicated: +-0.05mm.

(2)Microswitch adjustment unnecessary.

(3)Boost compensator stroke: BCL

(4)Damper spring setting

(5)Rack difference between N = N1 and N = N2

----------

BCL=2.5+-0.1mm N1=1050r/min N2=500r/min

----------

----------

BCL=2.5+-0.1mm N1=1050r/min N2=500r/min

----------

Speed control lever angle

F:Full speed

----------

----------

a=16.5deg+-5deg

----------

----------

a=16.5deg+-5deg

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=10deg+-5deg b=34deg+-3deg

----------

----------

a=10deg+-5deg b=34deg+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=40deg+-5deg b=73deg+-5deg

----------

----------

a=40deg+-5deg b=73deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(70deg)

----------

----------

a=(70deg)

Information:

Introduction

The problem that is identified below does not have a known permanent solution. Until a permanent solution is known, use the solution that is identified below.Problem

The diesel exhaust fluid (DEF) quality sensors are susceptible to seeing the following fault codes.

Table 1

J1939 CDL Code Description

3516-2 3100-2 Aftertreatment #1 DEF Concentration: Erratic, Intermittent or Incorrect

3516-12 3100-12 Aftertreatment #1 DEF Concentration: Failure

3516-16 E1365 High Aftertreatment #1 DEF Concentration

3516-18 E1364 Low Aftertreatment #1 DEF Concentration Solution

The latest software available in SIS has improvements in it related to the DEF quality sensor and these fault codes.

Ensure that the latest engine and aftertreatment software is installed prior to any hardware replacements.

Ensure that the latest DCU software is installed ( 539-3577 Engine Software (24V DCU) or 539-3576 Engine Software (12V DCU)).

In addition to the troubleshooting for these fault codes in SIS web, ensure that DEF quality is checked with both a refractometer and the 466-8796 Test Strips as outlined in Diesel Exhaust Fluid Quality - Test procedure in SIS.

Keep the DEF tank full when machine/engine will not be operated for an extended period of time to help reduce manifold exposure to ammonia gases in the DEF tank.Have seen cases of contamination where the test strips will not detect it if contamination is not hydrocarbon-based. In these instances, the DEF will appear to be cloudy when doing a visual comparison to a good, clean DEF sample.While working through issues related to these particular fault codes, email Blunier_Derek_W to provide troubleshooting information and documentation as to what was found.Information to Provide

PSRPT with histograms

Application History File

All troubleshooting resultsIf the DEF manifold does get replaced, provide the following:

Dealer code

Workorder number

Serial number

Hours at repair

DEF sample collected from top level of tank to be returned along with the DEF manifoldA Send It Back (SIB) will be created to get the DEF manifold returned.Downloading an Application History File

Illustration 1 g06233931

Click the appropriate ECM.

Click "Information".

Click "Warranty Report".

Illustration 2 g06233935

Click "ECM Information".

Click the "Yes" button.

Illustration 3 g06233938

Click "Additional Service".

Click the "Save" button.

The problem that is identified below does not have a known permanent solution. Until a permanent solution is known, use the solution that is identified below.Problem

The diesel exhaust fluid (DEF) quality sensors are susceptible to seeing the following fault codes.

Table 1

J1939 CDL Code Description

3516-2 3100-2 Aftertreatment #1 DEF Concentration: Erratic, Intermittent or Incorrect

3516-12 3100-12 Aftertreatment #1 DEF Concentration: Failure

3516-16 E1365 High Aftertreatment #1 DEF Concentration

3516-18 E1364 Low Aftertreatment #1 DEF Concentration Solution

The latest software available in SIS has improvements in it related to the DEF quality sensor and these fault codes.

Ensure that the latest engine and aftertreatment software is installed prior to any hardware replacements.

Ensure that the latest DCU software is installed ( 539-3577 Engine Software (24V DCU) or 539-3576 Engine Software (12V DCU)).

In addition to the troubleshooting for these fault codes in SIS web, ensure that DEF quality is checked with both a refractometer and the 466-8796 Test Strips as outlined in Diesel Exhaust Fluid Quality - Test procedure in SIS.

Keep the DEF tank full when machine/engine will not be operated for an extended period of time to help reduce manifold exposure to ammonia gases in the DEF tank.Have seen cases of contamination where the test strips will not detect it if contamination is not hydrocarbon-based. In these instances, the DEF will appear to be cloudy when doing a visual comparison to a good, clean DEF sample.While working through issues related to these particular fault codes, email Blunier_Derek_W to provide troubleshooting information and documentation as to what was found.Information to Provide

PSRPT with histograms

Application History File

All troubleshooting resultsIf the DEF manifold does get replaced, provide the following:

Dealer code

Workorder number

Serial number

Hours at repair

DEF sample collected from top level of tank to be returned along with the DEF manifoldA Send It Back (SIB) will be created to get the DEF manifold returned.Downloading an Application History File

Illustration 1 g06233931

Click the appropriate ECM.

Click "Information".

Click "Warranty Report".

Illustration 2 g06233935

Click "ECM Information".

Click the "Yes" button.

Illustration 3 g06233938

Click "Additional Service".

Click the "Save" button.

Have questions with 106671-9430?

Group cross 106671-9430 ZEXEL

Niigata-Urawa

Dpico

106671-9430

F 019 Z20 084

INJECTION-PUMP ASSEMBLY

DE12TI

DE12TI