Information injection-pump assembly

BOSCH

F 019 Z20 083

f019z20083

ZEXEL

106671-9420

1066719420

Rating:

Cross reference number

BOSCH

F 019 Z20 083

f019z20083

ZEXEL

106671-9420

1066719420

Zexel num

Bosch num

Firm num

Name

106671-9420

F 019 Z20 083

DPICO

INJECTION-PUMP ASSEMBLY

H100 Q

H100 Q

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

134424-1420

Overflow valve opening pressure

kPa

162

147

177

Overflow valve opening pressure

kgf/cm2

1.65

1.5

1.8

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

4

3.94

4

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.75 60.25

Cal 1-4 deg. 60 59.75 60.25

Difference between angles 2

Cyl.1-2 deg. 120 119.75 120.25

Cyl.1-2 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cal 1-3 deg. 240 239.75 240.25

Cal 1-3 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-5 deg. 300 299.75 300.25

Cal 1-5 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

A

Rack position

10.2

Pump speed

r/min

1150

1150

1150

Average injection quantity

mm3/st.

136

134

138

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Boost pressure

kPa

60

60

Boost pressure

mmHg

450

450

Injection quantity adjustment_02

Adjusting point

C

Rack position

6.3+-0.5

Pump speed

r/min

260

260

260

Average injection quantity

mm3/st.

8

5

11

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_03

Adjusting point

G

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

135

130

140

Fixing the lever

*

Boost pressure

kPa

60

60

Boost pressure

mmHg

450

450

Rack limit

*

Boost compensator adjustment

Pump speed

r/min

500

500

500

Rack position

R1(8.5)

Boost pressure

kPa

20

18.7

21.3

Boost pressure

mmHg

150

140

160

Boost compensator adjustment_02

Pump speed

r/min

500

500

500

Rack position

10

Boost pressure

kPa

46.7

46.7

46.7

Boost pressure

mmHg

350

350

350

Timer adjustment

Pump speed

r/min

765--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

715

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

850

Advance angle

deg.

2

1.5

2.5

Remarks

Finish

Finish

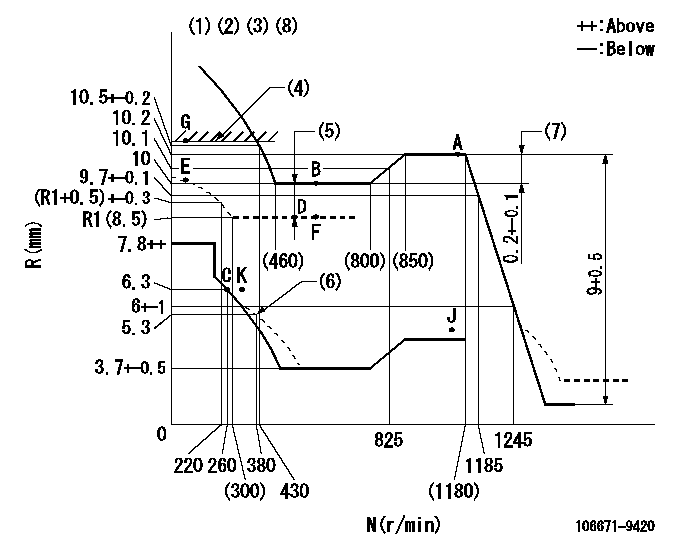

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Tolerance for racks not indicated: +-0.05mm.

(2)Microswitch not operating at delivery.

(3)Set idle at point K (N = N1, R = R1) and confirm that the injection quantity does not exceed Q1 at point J (N = N2).

(4)RACK LIMIT

(5)Boost compensator stroke: BCL

(6)Damper spring setting

(7)Rack difference between N = N3 and N = N4

(8)Boost compensator cancel stroke: BSL

----------

N1=300r/min R1=6.3mm N2=1150r/min Q1=3mm3/st BCL=1.5+-0.1mm N3=1150r/min N4=700r/min BSL=2.2mm

----------

----------

N1=300r/min R1=6.3mm N2=1150r/min Q1=3mm3/st BCL=1.5+-0.1mm N3=1150r/min N4=700r/min BSL=2.2mm

----------

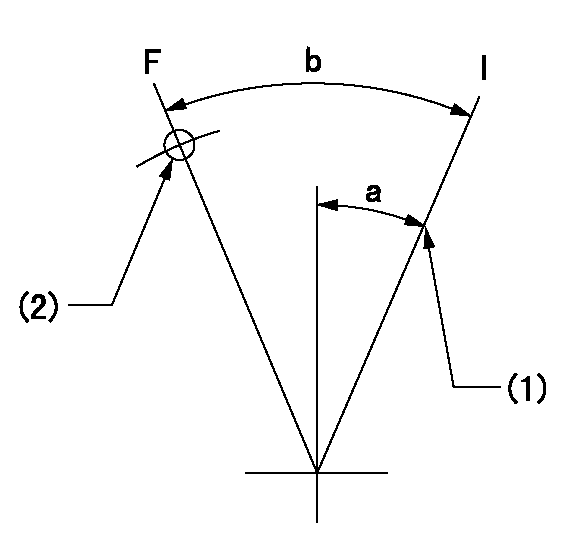

Speed control lever angle

F:Full speed

----------

----------

a=4deg+-5deg

----------

----------

a=4deg+-5deg

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

(2)Use the hole at R = aa

----------

aa=65mm

----------

a=22deg+-5deg b=23.5deg+-3deg

----------

aa=65mm

----------

a=22deg+-5deg b=23.5deg+-3deg

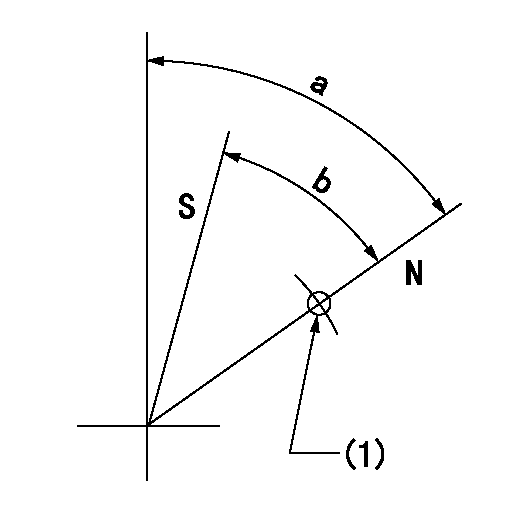

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the pin at R = aa

----------

aa=30mm

----------

a=64deg+-5deg b=44deg+-5deg

----------

aa=30mm

----------

a=64deg+-5deg b=44deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(50deg)

----------

----------

a=(50deg)

Information:

Table 7

464-8400 Air Lines Gp

Quantity Part Number Part Name

4 204-7562 Gasket

2 221-6861 Bellows As

2 227-4056 Gasket

1 386-7449 Housing

1 452-0270 Bracket

1 457-9114 Bracket

1 457-9115 Bracket

1 464-8144 Air Shutoff Gp

1 485-3715 Support

1 485-3716 Support

12 032-3237 Spacer

2 0L-1352 Bolt

8 0S-1587 Bolt

6 0S-1619 Bolt

20 118-0275 Washer

8 1A-1460 Bolt

4 1D-4609 Bolt

16 1F-7958 Full Nut

32 1K-6872 Locknut

4 2S-3567 Bolt

2 3E-4353 Hard Washer

64 3H-7654 Hard Washer

16 5J-4715 Washer

4 5P-6652 Washer

16 5P-8245 Hard Washer

2 8F-6350 Bolt

2 9S-8752 Full Nut

36 9X-8873 Bolt

Table 8

175-3842 Water Lines Cover Gp

Quantity Part Number Part Name

2 0S-1594 Bolt

2 1A-2029 Bolt

1 1N-5998 Plug

4 3V-3308 Hard Washer

1 6L-7817 O-Ring Seal

1 6V-1585 O-Ring Seal

1 8C-0562 O-Ring Seal

2 8N-9071 Valve As

2 8S-4950 Cap

1 134-5326 Cover

1 171-5262 Cover

Table 9

166-2166 Exhaust Fitting

Quantity Part Number Part Name

8 4J-4382 Pipe Plug

32 6V-5845 Bolt

32 6V-7742 Full Nut

32 8T-3282 Hard Washer

2 166-2161 Exhaust Adapter

2 166-4572 Gasket

Table 10

154-1252 Air Cleaner Adapter

Quantity Part Number Part Name

2 4W-3637 Hose

12 6V-5049 O-Ring Seal

12 9S-4191 Plug

16 116-8535 Clamp

2 153-8355 Adapter

Table 11

Turbocharger

Quantity Part Number Part Name

2 - Napier Turbocharger Turbocharger

A Special Rating Request (SRR) is required in order to determine the part number for the turbocharger. For the 3612 Engine there are two turbochargers per engine. To enter the Special Rating Request (SRR), contact the Application Support Center (ASC) using the link below:https://eomppp.cat.com

800-448-2400

Have questions with 106671-9420?

Group cross 106671-9420 ZEXEL

Niigata-Urawa

Dpico

106671-9420

F 019 Z20 083

INJECTION-PUMP ASSEMBLY

H100

H100