Information injection-pump assembly

BOSCH

F 019 Z20 076

f019z20076

ZEXEL

106671-9185

1066719185

Rating:

Cross reference number

BOSCH

F 019 Z20 076

f019z20076

ZEXEL

106671-9185

1066719185

Zexel num

Bosch num

Firm num

Name

106671-9185

F 019 Z20 076

DPICO

INJECTION-PUMP ASSEMBLY

H100 Q

H100 Q

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

134424-1420

Overflow valve opening pressure

kPa

162

147

177

Overflow valve opening pressure

kgf/cm2

1.65

1.5

1.8

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

4

3.94

4

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.75 60.25

Cal 1-4 deg. 60 59.75 60.25

Difference between angles 2

Cyl.1-2 deg. 120 119.75 120.25

Cyl.1-2 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cal 1-3 deg. 240 239.75 240.25

Cal 1-3 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-5 deg. 300 299.75 300.25

Cal 1-5 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

A

Rack position

9.7

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

130

128

132

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Boost pressure

kPa

53.3

53.3

Boost pressure

mmHg

400

400

Injection quantity adjustment_02

Adjusting point

C

Rack position

6.4+-0.5

Pump speed

r/min

260

260

260

Average injection quantity

mm3/st.

11

9

13

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_03

Adjusting point

G

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

125

120

130

Fixing the lever

*

Boost pressure

kPa

53.3

53.3

Boost pressure

mmHg

400

400

Rack limit

*

Boost compensator adjustment

Pump speed

r/min

550

550

550

Rack position

R1(8.8)

Boost pressure

kPa

22.7

22.7

22.7

Boost pressure

mmHg

170

170

170

Boost compensator adjustment_02

Pump speed

r/min

550

550

550

Rack position

R1+0.45

Boost pressure

kPa

28.7

28

29.4

Boost pressure

mmHg

215

210

220

Boost compensator adjustment_03

Pump speed

r/min

550

550

550

Rack position

(9.7)

Boost pressure

kPa

40

40

40

Boost pressure

mmHg

300

300

300

Timer adjustment

Pump speed

r/min

800--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

750

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1000

Advance angle

deg.

2.8

2.3

3.3

Remarks

Finish

Finish

Test data Ex:

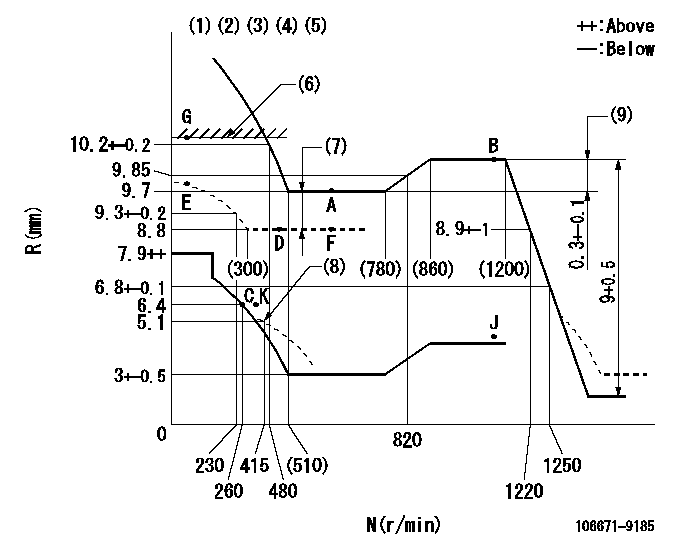

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Lever ratio: RT

(2)Target shim dimension: TH

(3)Tolerance for racks not indicated: +-0.05mm.

(4)Boost compensator cancel stroke: BSL

(5)Set idle at point K (N = N1, R = R1) and confirm that the injection quantity does not exceed Q1 at point J (N = N2).

(6)RACK LIMIT

(7)Boost compensator stroke: BCL

(8)Damper spring setting

(9)Rack difference between N = N3 and N = N4

----------

RT=1 TH=2.1mm BSL=2.2mm N1=300r/min R1=6.4mm N2=1150r/min Q1=3mm3/st BCL=(0.9)mm N3=1150r/min N4=700r/min

----------

----------

RT=1 TH=2.1mm BSL=2.2mm N1=300r/min R1=6.4mm N2=1150r/min Q1=3mm3/st BCL=(0.9)mm N3=1150r/min N4=700r/min

----------

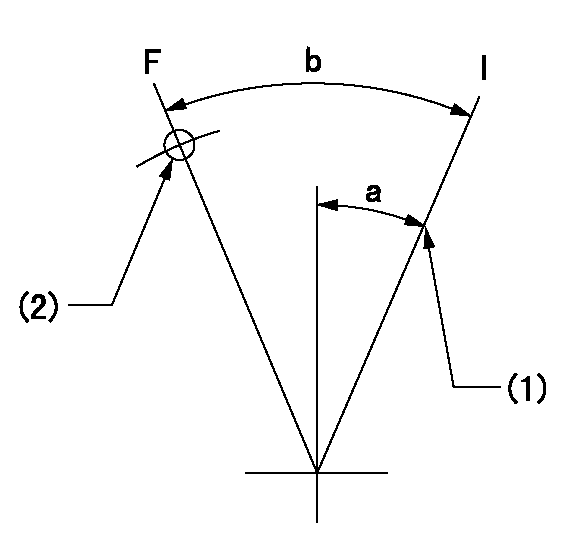

Speed control lever angle

F:Full speed

----------

----------

a=(7deg)+-5deg

----------

----------

a=(7deg)+-5deg

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

(2)Use the hole at R = aa

----------

aa=65mm

----------

a=22deg+-5deg b=24.5deg+-3deg

----------

aa=65mm

----------

a=22deg+-5deg b=24.5deg+-3deg

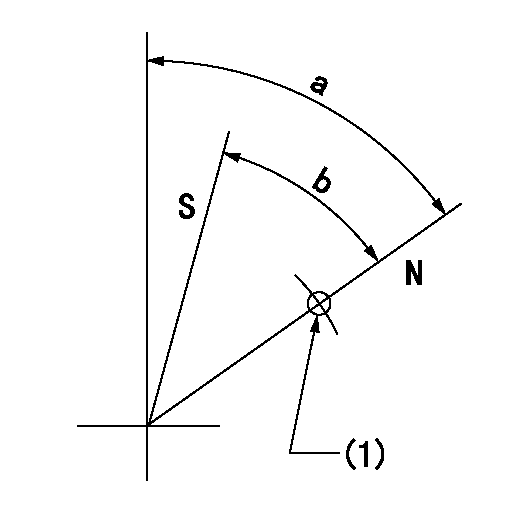

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the pin at R = aa

----------

aa=37mm

----------

a=64deg+-5deg b=44deg+-5deg

----------

aa=37mm

----------

a=64deg+-5deg b=44deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=13deg

----------

a=(50deg)

----------

aa=13deg

----------

a=(50deg)

Information:

Introduction

The problem that is identified below does not have a known permanent solution. Until a permanent solution is known, use the solution that is identified below.Problem

There have been some isolated instances of issues with the Diesel Particulate Filter (DPF) on certain C3.4B engines.Solution

Caterpillar is aware of this problem. Follow the procedure that is detailed below.

Table 1

Required Tools

Tool Part Number Part Description Qty

A 233-7191 Hose Cleaner Gp 1

Obtain a fuel sample from the engine.

Obtain a lubricating oil sample from the engine.

Attach a copy of the full service history of the engine to the Service Information Systems (SIMSi) report. Include the change history of the following components:

Engine oil

Engine oil filter

Engine fuel filter

Crankcase breather filter

Ensure that the breather element is clean and free from wear or damage. Replace the breather element. Refer to Operation and Maintenance Manual, Engine Crankcase Breather Element - Replace for the correct procedure. Ensure that the inlet hose is clean and free from restriction. If the inlet hose requires replacing, refer to Disassembly and Assembly, Crankcase Breather - Install for the correct procedure.

Determine the service hours of the engine air cleaner element. Ensure that the engine air cleaner element is clean and free from wear, damage, or restriction. If necessary, replace the engine air cleaner element. Refer to Operation and Maintenance Manual, Engine Air Cleaner Element (Single Element) - Inspect/Clean/Replace for the correct procedure. Ensure that the hose assemblies are clean and free from restriction and dust.

Inspect the inlet and outlet hoses of the turbocharger for the presence of excessive lubricating oil. If necessary, take photographs inside both inlet and outlet hoses. If necessary, take photographs inside the compressor housing for the inlet and outlet. If excessive lubricating oil is found, replace the turbocharger. Refer to Disassembly and Assembly, Turbocharger

The problem that is identified below does not have a known permanent solution. Until a permanent solution is known, use the solution that is identified below.Problem

There have been some isolated instances of issues with the Diesel Particulate Filter (DPF) on certain C3.4B engines.Solution

Caterpillar is aware of this problem. Follow the procedure that is detailed below.

Table 1

Required Tools

Tool Part Number Part Description Qty

A 233-7191 Hose Cleaner Gp 1

Obtain a fuel sample from the engine.

Obtain a lubricating oil sample from the engine.

Attach a copy of the full service history of the engine to the Service Information Systems (SIMSi) report. Include the change history of the following components:

Engine oil

Engine oil filter

Engine fuel filter

Crankcase breather filter

Ensure that the breather element is clean and free from wear or damage. Replace the breather element. Refer to Operation and Maintenance Manual, Engine Crankcase Breather Element - Replace for the correct procedure. Ensure that the inlet hose is clean and free from restriction. If the inlet hose requires replacing, refer to Disassembly and Assembly, Crankcase Breather - Install for the correct procedure.

Determine the service hours of the engine air cleaner element. Ensure that the engine air cleaner element is clean and free from wear, damage, or restriction. If necessary, replace the engine air cleaner element. Refer to Operation and Maintenance Manual, Engine Air Cleaner Element (Single Element) - Inspect/Clean/Replace for the correct procedure. Ensure that the hose assemblies are clean and free from restriction and dust.

Inspect the inlet and outlet hoses of the turbocharger for the presence of excessive lubricating oil. If necessary, take photographs inside both inlet and outlet hoses. If necessary, take photographs inside the compressor housing for the inlet and outlet. If excessive lubricating oil is found, replace the turbocharger. Refer to Disassembly and Assembly, Turbocharger

Have questions with 106671-9185?

Group cross 106671-9185 ZEXEL

Dpico

106671-9185

F 019 Z20 076

INJECTION-PUMP ASSEMBLY

H100

H100