Information injection-pump assembly

ZEXEL

106671-9020

1066719020

KOMATSU

6152711410

6152711410

Rating:

Cross reference number

ZEXEL

106671-9020

1066719020

KOMATSU

6152711410

6152711410

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.8

3.75

3.85

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

10.1

Pump speed

r/min

1050

1050

1050

Average injection quantity

mm3/st.

152.5

150.5

154.5

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Boost pressure

kPa

86.6

86.6

Boost pressure

mmHg

650

650

Injection quantity adjustment_02

Adjusting point

B

Rack position

5+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

18

16.5

19.5

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

500

500

500

Rack position

8.3

Boost pressure

kPa

40

37.3

42.7

Boost pressure

mmHg

300

280

320

Boost compensator adjustment_02

Pump speed

r/min

500

500

500

Rack position

11.1

Boost pressure

kPa

73.3

66.6

80

Boost pressure

mmHg

550

500

600

Timer adjustment

Pump speed

r/min

700--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

650

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

850

Advance angle

deg.

1.2

0.7

1.7

Timer adjustment_04

Pump speed

r/min

1050

Advance angle

deg.

3

2.5

3.5

Remarks

Finish

Finish

Test data Ex:

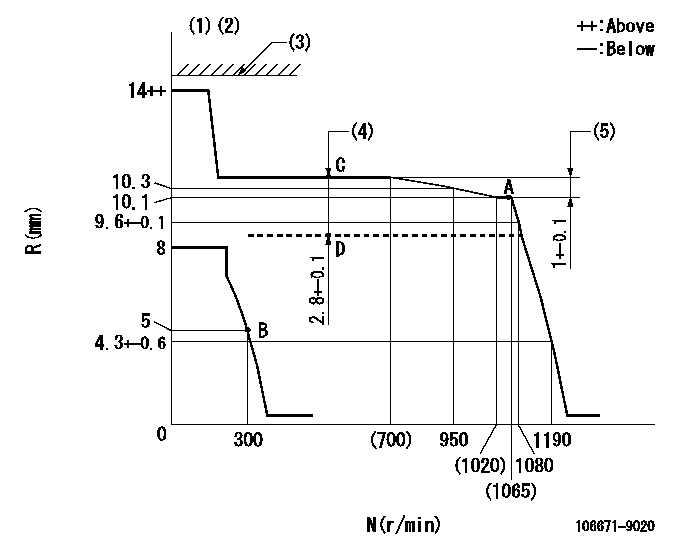

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Excess fuel lever not set.

(4)Boost compensator stroke

(5)Rack difference between N = N1 and N = N2

----------

K=14 N1=1050r/min N2=500r/min

----------

----------

K=14 N1=1050r/min N2=500r/min

----------

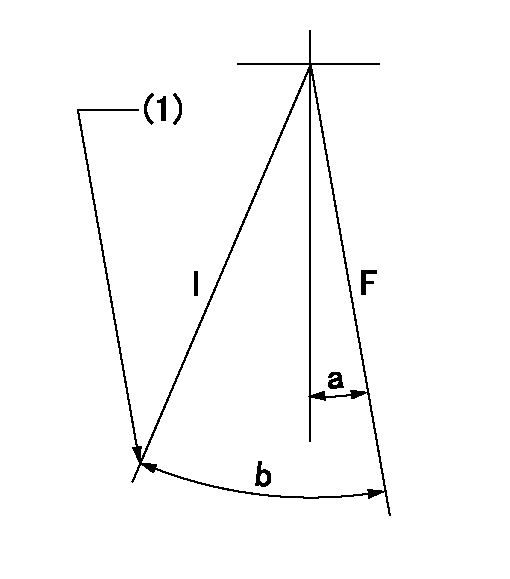

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=9deg+-5deg b=27deg+-5deg

----------

----------

a=9deg+-5deg b=27deg+-5deg

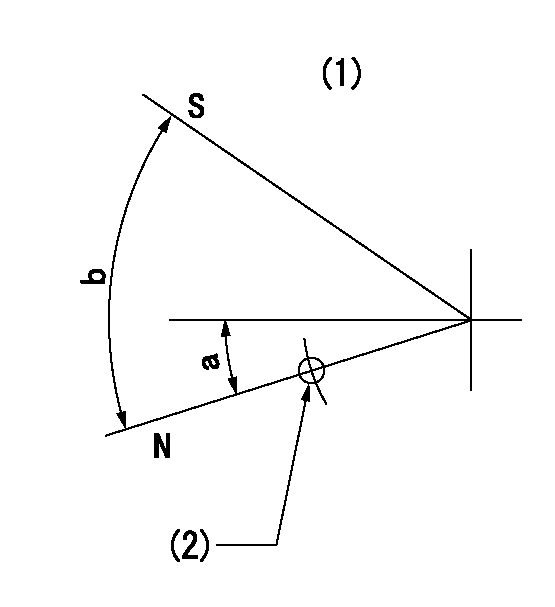

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)No return spring

(2)Use hole at R = aa (left hand side)

----------

aa=27mm

----------

a=26.5deg+-5deg b=53deg+-5deg

----------

aa=27mm

----------

a=26.5deg+-5deg b=53deg+-5deg

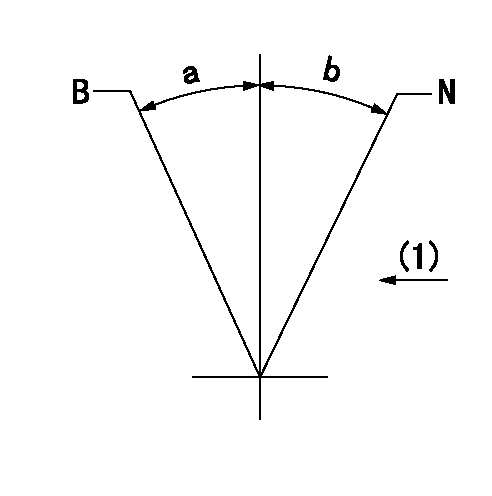

0000001101

N:Normal

B:When boosted

(1)Drive side

----------

----------

a=(15deg) b=(15deg)

----------

----------

a=(15deg) b=(15deg)

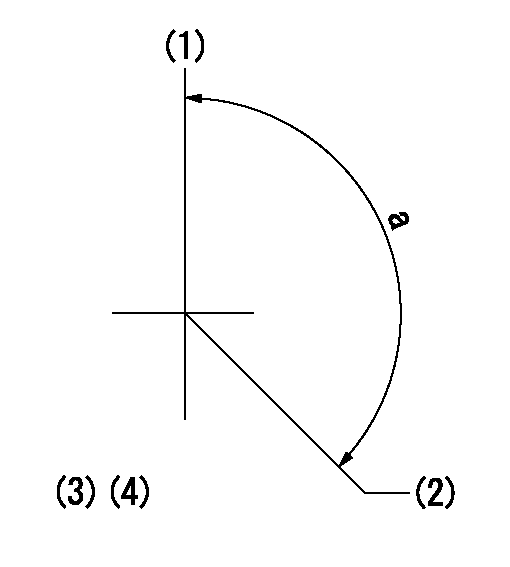

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(150deg)

----------

----------

a=(150deg)

Information:

Table 1

Repair Kit Part Numbers for Quick Connect DEF Line Fittings

473-2053 5/16"-90 Degree Kit

473-2055 5/16"- Straight Kit

473-2056 3/8"-90 Degree Kit

473-2057 3/8"- Straight Kit Rework Procedure

Table 2

Required Tools

Part Number Part Name

1U-7648 Tube Cutter

Illustration 1 g06433660

Cut the connector end on the corrugated section with the cutter.

Illustration 2 g06433665

Cut the two wires with a tie cutter.

Illustration 3 g06433668

Use a knife or sharp blade to cut the outer sheathing off. Ensure not to cut or damage the inner fluid hose.

Illustration 4 g06433669

Install the hose clamp provided first before installing the connector. Use appropriate size (3/8th or 5/16th) and type (90 degree or straight) fitting.

Illustration 5 g06433672

Fasten the clamp until the two jaws are either in contact or about 2 to 3 mm (0.08 to 0.1 inch) apart.