Information injection-pump assembly

ZEXEL

106671-8981

1066718981

HINO

220009580A

220009580a

Rating:

Service parts 106671-8981 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

23600-2950A

12.

Open Pre:MPa(Kqf/cm2)

14.7{150}/21.6{220}

14.

NOZZLE

Include in #1:

106671-8981

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

106671-8981

1066718981

HINO

220009580A

220009580a

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

134424-0920

Overflow valve opening pressure

kPa

162

147

177

Overflow valve opening pressure

kgf/cm2

1.65

1.5

1.8

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

4.6

4.54

4.6

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.75 60.25

Cal 1-4 deg. 60 59.75 60.25

Difference between angles 2

Cyl.1-2 deg. 120 119.75 120.25

Cyl.1-2 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cal 1-3 deg. 240 239.75 240.25

Cal 1-3 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-5 deg. 300 299.75 300.25

Cal 1-5 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

-

Rack position

10.6

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

113

110

116

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

7+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

9

6

12

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(10.6)

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

113

111

115

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+0.25

Pump speed

r/min

1075

1075

1075

Average injection quantity

mm3/st.

121.5

115.5

127.5

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

I

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

165

165

185

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

750-50

Advance angle

deg.

0.3

Timer adjustment_02

Pump speed

r/min

1075-50

Advance angle

deg.

5.5

5.2

5.8

Remarks

Finish

Finish

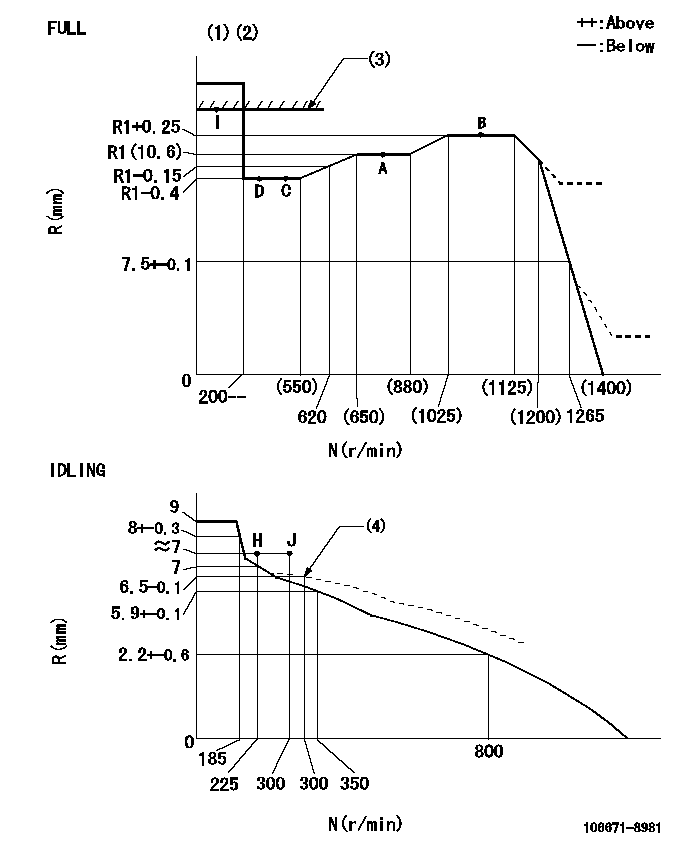

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Damper spring setting

----------

T1=AE36

----------

----------

T1=AE36

----------

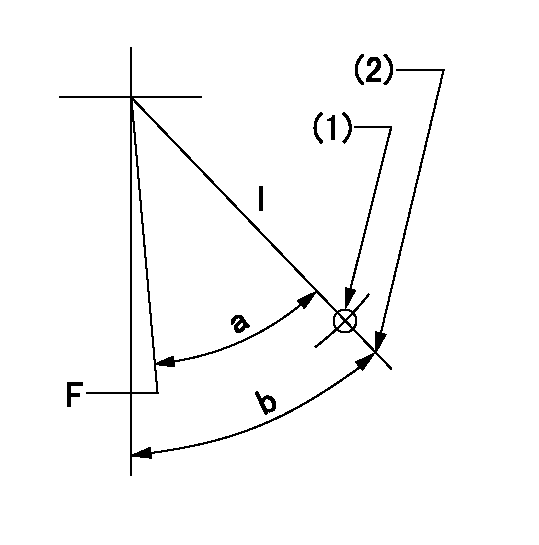

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt set position 'H'

----------

aa=42.5mm

----------

a=34deg+-3deg b=36deg+-5deg

----------

aa=42.5mm

----------

a=34deg+-3deg b=36deg+-5deg

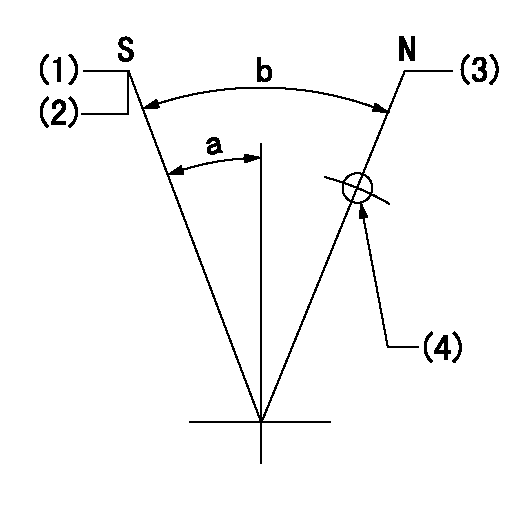

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Pump speed aa, rack position bb

(2)Set the stopper screw. (After setting, apply red paint.)

(3)Set the stopper screw at this lever angle.

(4)Use the hole above R = cc

----------

aa=0r/min bb=1.5+-0.3mm cc=30mm

----------

a=22deg+-5deg b=42deg+-5deg

----------

aa=0r/min bb=1.5+-0.3mm cc=30mm

----------

a=22deg+-5deg b=42deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(3deg)

----------

----------

a=(3deg)

Information:

Caterpillar Warranty Coverage

Caterpillar warrants the DPF according to the time periods, whichever comes first. Refer to table

Table 1

Engine Type Engine Size Minimum Warranty Period

Off Road (1) Under 25 hp, and for constant speed engines rated under 50 hp with rated speeds greater than or equal to 3,000 RPM 3 years or 1,600 hours

At or above 25 hp and under 50 hp 4 years or 2,600 hours

At or above 50 hp 5 years or 4,200 hours

( 1 ) Includes portable engines, stationary, marine, locomotives, TRU, and APU.If any emission-related part of your diesel emission control system is defective in design, materials, workmanship, or operation of the diesel emission control system thus causing the diesel emission control system to fail to conform to the emission control performance level the diesel emission control system was verified to, or to the requirements in the "California Code of Regulations Title 13 Sections 2700 to 2706 and 2710", within the warranty period, as defined above, Caterpillar will repair or replace the diesel emission control system, including parts and labor.In addition, Caterpillar will replace or repair the engine components to the condition prior to the failure, including parts and labor, for damage to the engine proximately caused by the verified diesel emission control strategy. This warranty also includes those relevant diagnostic expenses in the case in which a warranty claim is valid. Caterpillar may, instead pay the fair market value of the engine prior to the time the failure occurs.Owner Warranty Responsibility

As the (vehicle, engine, equipment) owner, you are responsible for performing the required maintenance described in your owners manual. Caterpillar recommends that you retain all maintenance records and receipts for maintenance expenses for your vehicle, engine, or equipment, and diesel emission control system. If you do not keep your receipts or fail to perform all scheduled maintenance, Caterpillar may have grounds to deny warranty coverage. You are responsible for presenting your vehicle, equipment, or engine, and diesel emission control system to a (applicant name) dealer as soon as a problem is detected. The warranty repair or replacement should be completed in a reasonable amount of time, not to exceed 30 days. If a replacement is needed, this process may be extended to 90 days should a replacement not be available, but must be performed as soon as a replacement becomes available.If you have questions regarding your warranty rights and responsibilities, contact (Insert chosen applicant contact) at:California Air Resources Board

9528 Telstar Avenue

El Monte, CA 91731

helpline@arb.ca.gov.

1-877-CAT-0909800-363-7664Refer to Special Instruction, REHS9213, "Caterpillar Post Installation Compatibility Assessment for Stationary Engines" and Special Instructions, REHS9214, "Post Installation Compatibility Assessment for NEW Stationary Engines".Register warranty per Caterpillar form Special Instruction, REHS5097, "Instructions to Register the Retrofit and Submit Service Reporting {1000, 3000, 7000, 7570}"Maintain all records of installation, pictures, warranty claims, and PICA Form. Provide training for all operation and maintenance.

Caterpillar warrants the DPF according to the time periods, whichever comes first. Refer to table

Table 1

Engine Type Engine Size Minimum Warranty Period

Off Road (1) Under 25 hp, and for constant speed engines rated under 50 hp with rated speeds greater than or equal to 3,000 RPM 3 years or 1,600 hours

At or above 25 hp and under 50 hp 4 years or 2,600 hours

At or above 50 hp 5 years or 4,200 hours

( 1 ) Includes portable engines, stationary, marine, locomotives, TRU, and APU.If any emission-related part of your diesel emission control system is defective in design, materials, workmanship, or operation of the diesel emission control system thus causing the diesel emission control system to fail to conform to the emission control performance level the diesel emission control system was verified to, or to the requirements in the "California Code of Regulations Title 13 Sections 2700 to 2706 and 2710", within the warranty period, as defined above, Caterpillar will repair or replace the diesel emission control system, including parts and labor.In addition, Caterpillar will replace or repair the engine components to the condition prior to the failure, including parts and labor, for damage to the engine proximately caused by the verified diesel emission control strategy. This warranty also includes those relevant diagnostic expenses in the case in which a warranty claim is valid. Caterpillar may, instead pay the fair market value of the engine prior to the time the failure occurs.Owner Warranty Responsibility

As the (vehicle, engine, equipment) owner, you are responsible for performing the required maintenance described in your owners manual. Caterpillar recommends that you retain all maintenance records and receipts for maintenance expenses for your vehicle, engine, or equipment, and diesel emission control system. If you do not keep your receipts or fail to perform all scheduled maintenance, Caterpillar may have grounds to deny warranty coverage. You are responsible for presenting your vehicle, equipment, or engine, and diesel emission control system to a (applicant name) dealer as soon as a problem is detected. The warranty repair or replacement should be completed in a reasonable amount of time, not to exceed 30 days. If a replacement is needed, this process may be extended to 90 days should a replacement not be available, but must be performed as soon as a replacement becomes available.If you have questions regarding your warranty rights and responsibilities, contact (Insert chosen applicant contact) at:California Air Resources Board

9528 Telstar Avenue

El Monte, CA 91731

helpline@arb.ca.gov.

1-877-CAT-0909800-363-7664Refer to Special Instruction, REHS9213, "Caterpillar Post Installation Compatibility Assessment for Stationary Engines" and Special Instructions, REHS9214, "Post Installation Compatibility Assessment for NEW Stationary Engines".Register warranty per Caterpillar form Special Instruction, REHS5097, "Instructions to Register the Retrofit and Submit Service Reporting {1000, 3000, 7000, 7570}"Maintain all records of installation, pictures, warranty claims, and PICA Form. Provide training for all operation and maintenance.