Information injection-pump assembly

BOSCH

9 400 610 899

9400610899

ZEXEL

106671-8971

1066718971

Rating:

Service parts 106671-8971 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

23600-2030A

12.

Open Pre:MPa(Kqf/cm2)

19.6{200}

15.

NOZZLE SET

Include in #1:

106671-8971

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 610 899

9400610899

ZEXEL

106671-8971

1066718971

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

134424-0920

Overflow valve opening pressure

kPa

162

147

177

Overflow valve opening pressure

kgf/cm2

1.65

1.5

1.8

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.3

3.2

3.3

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

9.4

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

188.5

186.5

190.5

Max. variation between cylinders

%

0

-4

4

Basic

*

Fixing the rack

*

Boost pressure

kPa

107

107

Boost pressure

mmHg

800

800

Injection quantity adjustment_02

Adjusting point

B

Rack position

9

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

170

167

173

Max. variation between cylinders

%

0

-4

4

Fixing the rack

*

Boost pressure

kPa

107

107

Boost pressure

mmHg

800

800

Injection quantity adjustment_03

Adjusting point

D

Rack position

4.7+-0.5

Pump speed

r/min

360

360

360

Average injection quantity

mm3/st.

9.5

6.5

12.5

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

550

550

550

Rack position

R1-0.8

Boost pressure

kPa

66.7

66.7

66.7

Boost pressure

mmHg

500

500

500

Boost compensator adjustment_02

Pump speed

r/min

550

550

550

Rack position

R1(11.3)

Boost pressure

kPa

93.3

86.6

100

Boost pressure

mmHg

700

650

750

Timer adjustment

Pump speed

r/min

850--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

800

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

900

Advance angle

deg.

0.5

0

1

Timer adjustment_04

Pump speed

r/min

-

Advance angle

deg.

1.5

1.5

1.5

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

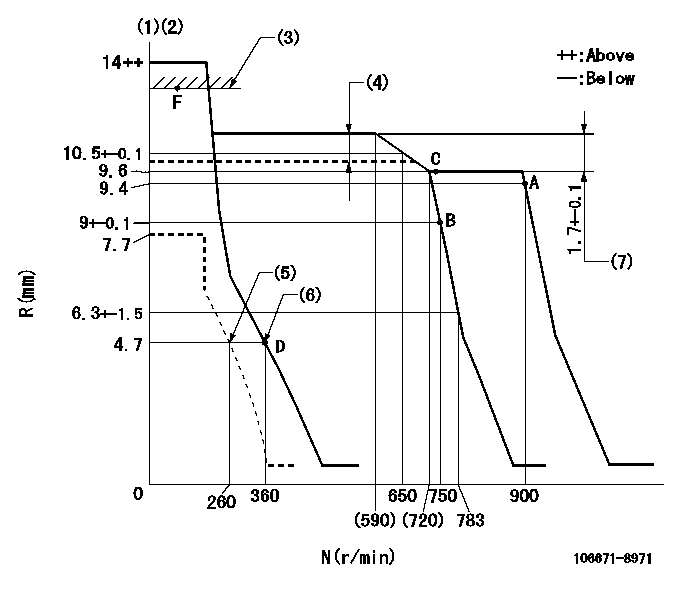

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Notch fixed: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Boost compensator excessive fuel lever at operation (at 0 boost pressure): L1

(4)Boost compensator stroke: BCL

(5)Set idle sub-spring

(6)Main spring setting

(7)Rack difference between N = N1 and N = N2

----------

K=6 L1=13+-0.1mm BCL=0.8+-0.05mm N1=750r/min N2=550r/min

----------

----------

K=6 L1=13+-0.1mm BCL=0.8+-0.05mm N1=750r/min N2=550r/min

----------

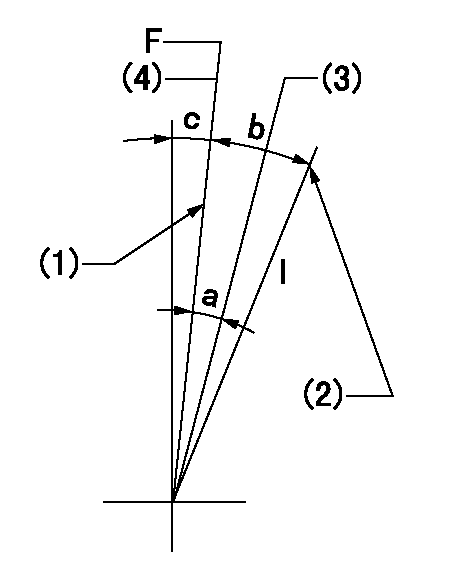

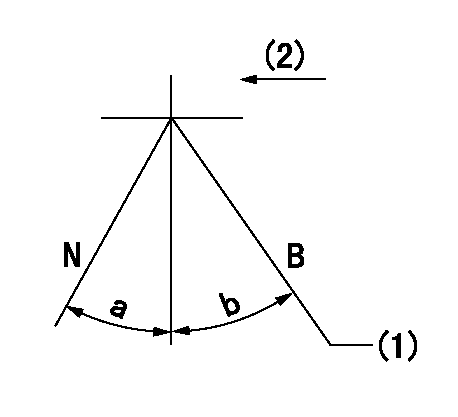

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

(2)Stopper bolt setting

(3)When pump speed set at aa

(4)Set the pump speed at bb (at delivery)

----------

aa=750r/min bb=900r/min

----------

a=(5deg)+-5deg b=(20deg)+-5deg c=(3deg)+-5deg

----------

aa=750r/min bb=900r/min

----------

a=(5deg)+-5deg b=(20deg)+-5deg c=(3deg)+-5deg

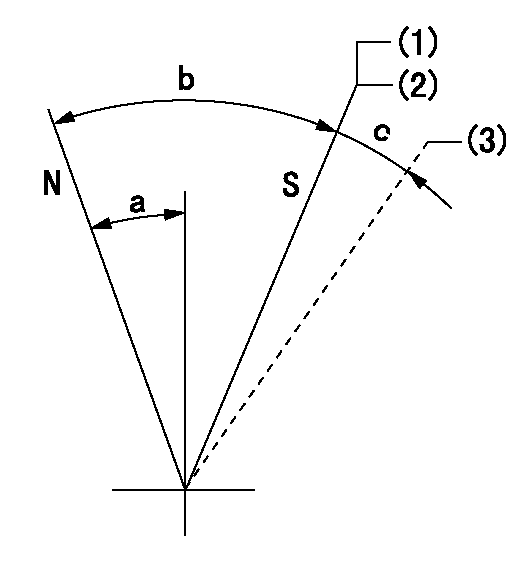

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Contacts inner stopper.

(2)Rack position aa or less, pump speed bb

(3)Contacts outer stopper.

----------

aa=4.2mm bb=0r/min

----------

a=27deg+-5deg b=53deg+-5deg c=(11deg)

----------

aa=4.2mm bb=0r/min

----------

a=27deg+-5deg b=53deg+-5deg c=(11deg)

0000001101

N:Normal

B:When boosted

(1)Rack position = aa at boost pressure 0.

(2)Drive side

----------

aa=13+-0.1mm

----------

a=(15deg) b=(13deg)

----------

aa=13+-0.1mm

----------

a=(15deg) b=(13deg)

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(0deg)

----------

----------

a=(0deg)

Information:

Illustration 6 g06375966

Current hose routing

(E) 3U-2752 Clip

Illustration 7 g06375968

(D3) 32.31 mm (1.272 inch)

(D4) 80.00 mm (3.150 inch)

(1) 178-7023 Boss

Illustration 8 g06375967

New hose routing

(1) 178-7023 Boss

(2) 420-5299 Clip

Remove clip (E) and install boss (1) per the dimensions and secure the hose using two double clips (2), as shown in Illustration 6, Illustration 7, and Illustration 8.Changes to CEM Line Routing for 730C2, 730C2 EJ, 730, and 735 Articulated Trucks

Illustration 9 g06376002

Current hose routing

(F) 421-9627 Bracket As

(G) 3U-2752 Clip

(H) 7K-1181 Cable Strap

Remove bracket assembly (F), clips (G), strap cable (H), and other mounting hardware, as shown in Illustration 9.

Illustration 10 g06376255

New hose routing

(2) 420-5299 Clip

Install two double clips (2) as shown in Illustration 10.Note: The hose routing simplifies the installation and provides additional clearance to the oil gallery on the right-hand side of the machine.Changes to DEF cooling Lines Routing (To/From Tank) for all High Regulated Countries (HRC) Machines

Illustration 11 g06376256

Current hose routing

(J) 312-0288 Clamp

Illustration 12 g06376257

New hose routing

(3) 520-7003 ClampRemove old clamps (J) and replace with the new clamps (3), as shown in Illustration 11 and Illustration 12.Changes to DEF Cooling Lines Routing (To Pump- Both ends) for all HRC Machines

Illustration 13 g06376263

Current clamp

(J) 312-0288 Clamp

Illustration 14 g06376264

New clamp

(3) 520-7003 Clamp

Illustration 15 g06376266

Current clamp

(J) 312-0288 Clamp

Illustration 16 g06376267

New clamp

(3) 520-7003 ClampRemove old clamps (J) and replace with the new clamps (3), as shown in Illustration 13, Illustration 14, Illustration 15, and Illustration 16.Changes to DEF Cooling Lines (From Pump- Both ends) Routing for all HRC Machines

Illustration 17 g06376285

Current clamp

(K) 433-0933 Clamp

Illustration 18 g06376288

New clamp

(4) 520-7002 ClampRemove existing clamps (K) and replace with the new clamps (4), as shown in Illustration 17 and Illustration 18.