Information injection-pump assembly

BOSCH

9 400 617 027

9400617027

ZEXEL

106671-8882

1066718882

HINO

220801722B

220801722b

Rating:

Cross reference number

BOSCH

9 400 617 027

9400617027

ZEXEL

106671-8882

1066718882

HINO

220801722B

220801722b

Zexel num

Bosch num

Firm num

Name

106671-8882

9 400 617 027

220801722B HINO

INJECTION-PUMP ASSEMBLY

K13C-TK K

K13C-TK K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

134424-4420

Overflow valve opening pressure

kPa

162

147

177

Overflow valve opening pressure

kgf/cm2

1.65

1.5

1.8

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.9

3.84

3.9

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.75 60.25

Cal 1-4 deg. 60 59.75 60.25

Difference between angles 2

Cyl.1-2 deg. 120 119.75 120.25

Cyl.1-2 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cal 1-3 deg. 240 239.75 240.25

Cal 1-3 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-5 deg. 300 299.75 300.25

Cal 1-5 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

A

Rack position

9.9

Pump speed

r/min

550

550

550

Average injection quantity

mm3/st.

189.5

187.5

191.5

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Boost pressure

kPa

53.3

53.3

Boost pressure

mmHg

400

400

Injection quantity adjustment_02

Adjusting point

B

Rack position

9.45

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

169.5

166.5

172.5

Max. variation between cylinders

%

0

-5

5

Fixing the lever

*

Boost pressure

kPa

53.3

53.3

Boost pressure

mmHg

400

400

Injection quantity adjustment_03

Adjusting point

D

Rack position

3.5+-0.5

Pump speed

r/min

250

250

250

Average injection quantity

mm3/st.

10.5

7.5

13.5

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_04

Adjusting point

E

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

200

195

205

Fixing the lever

*

Boost pressure

kPa

53.3

53.3

Boost pressure

mmHg

400

400

Rack limit

*

Injection quantity adjustment_05

Adjusting point

H

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

110

110

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

550

550

550

Rack position

(7.8)

Boost pressure

kPa

13.3

13.3

15.3

Boost pressure

mmHg

100

100

115

Boost compensator adjustment_02

Pump speed

r/min

550

550

550

Rack position

9.9

Boost pressure

kPa

40

40

40

Boost pressure

mmHg

300

300

300

Timer adjustment

Pump speed

r/min

700--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

650

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1000

Advance angle

deg.

4

3.7

4.3

Remarks

Finish

Finish

Test data Ex:

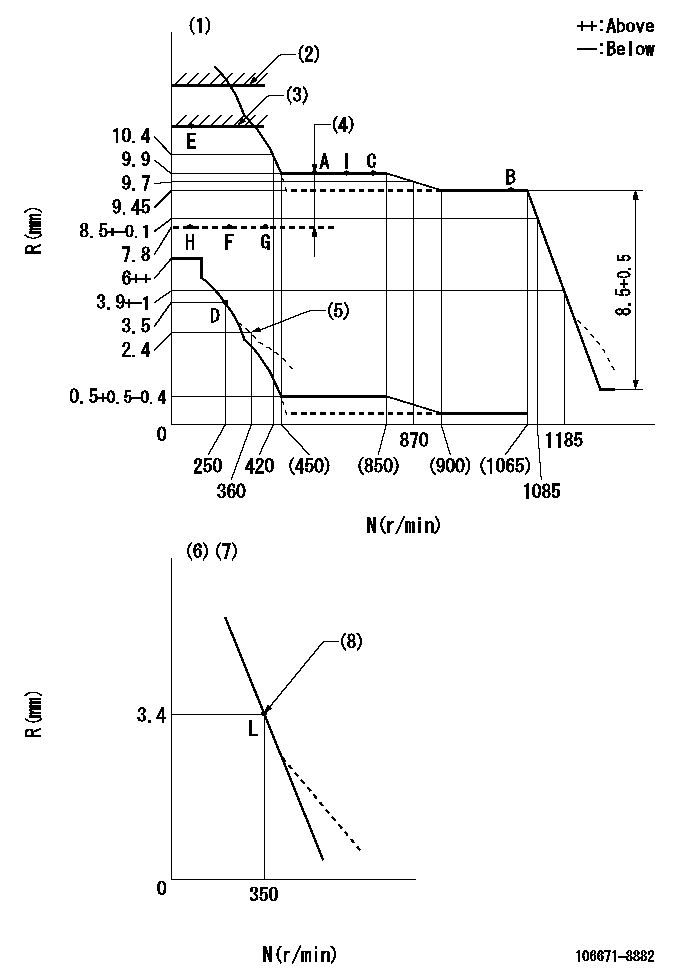

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Tolerance for racks not indicated: +-0.05mm.

(2)Stop lever setting: R1

(3)RACK LIMIT

(4)Boost compensator stroke: BCL

(5)Damper spring setting

(6)Variable speed specification: idling adjustment

(7)Fix the lever at the full-load position at delivery.

(8)Main spring setting

----------

R1=(12.1)+0.5mm BCL=(2.1)mm

----------

----------

R1=(12.1)+0.5mm BCL=(2.1)mm

----------

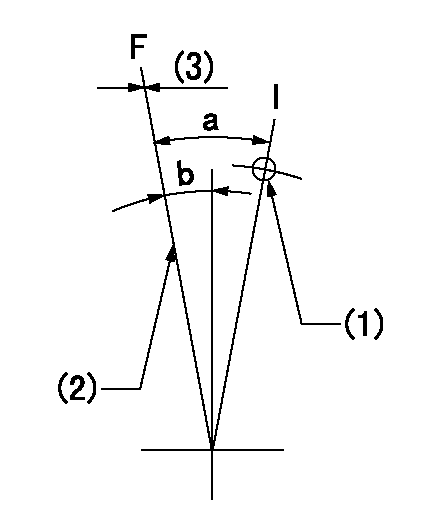

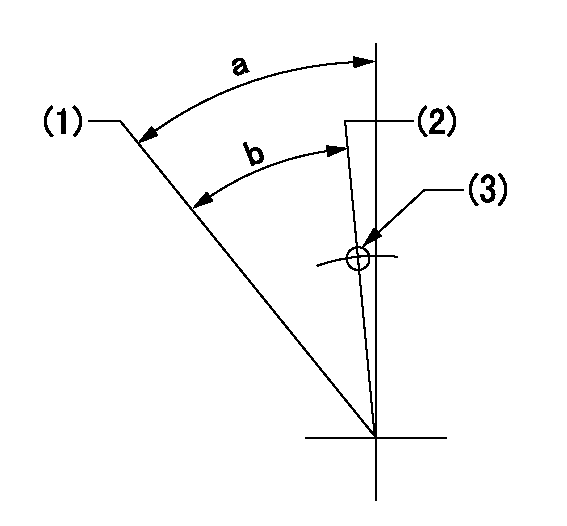

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt setting

(3)Set the stopper bolt (fixed at full-load position at delivery.)

----------

aa=130mm

----------

a=(13deg)+-5deg b=(1deg)+-5deg

----------

aa=130mm

----------

a=(13deg)+-5deg b=(1deg)+-5deg

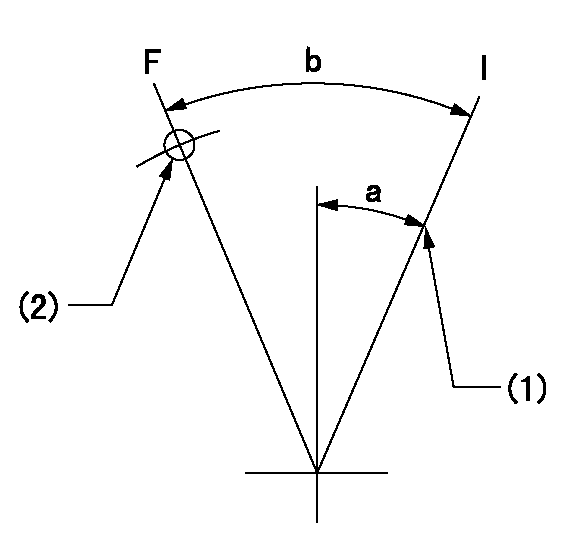

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

(2)Use the hole at R = aa

----------

aa=50mm

----------

a=25deg+-5deg b=34.5deg+-3deg

----------

aa=50mm

----------

a=25deg+-5deg b=34.5deg+-3deg

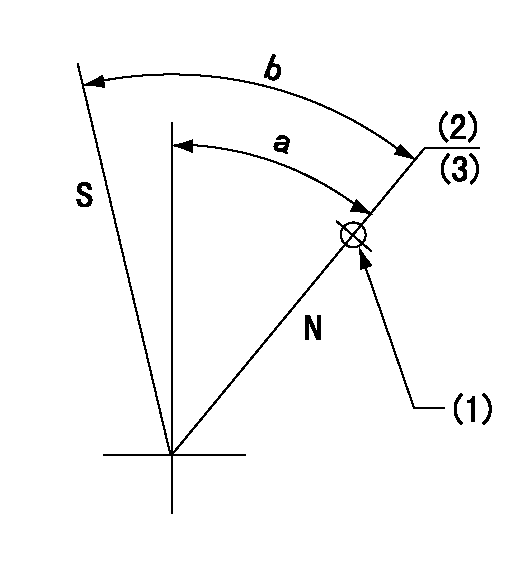

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the hole at R = aa

(2)Set the rack position at bb before adjusting the governor

(3)Set the stopper screw. (After setting, apply red paint.)

----------

aa=36mm bb=(12.1)+0.5mm

----------

a=35deg+-5deg b=39deg+-5deg

----------

aa=36mm bb=(12.1)+0.5mm

----------

a=35deg+-5deg b=39deg+-5deg

0000001201

(1)Minimum - maximum speed specification

(2)Variable speed specification

(3)Use the hole at R = aa

----------

aa=112mm

----------

a=(18.5deg)+-5deg b=(16.5deg)

----------

aa=112mm

----------

a=(18.5deg)+-5deg b=(16.5deg)

0000001501 LEVER

2-stage changeover lever adjustment

(A) Speed lever

(B) Load lever

(C) 2-stage changeover lever

(D) Link

(E) Bolt

(G) Variable speed specifications

(H) Minimum maximum speed specifications

F:Full speed

I:Idle

1. Minimum-maximum speed specification adjustment (when running)

(1)After completing governor adjustment, hold the 2-stage changeover lever (C) so that the speed lever (A) contacts the full speed stopper.

(2)In this condition, the load lever is held in the idle position.

(3)Adjust bolt (E) so that the clearance between the pin underneath lever (C) and the end of the long groove in link (D) is L.

(4)Lock using the nut.

2. Variable speed specification adjustment (at operation)

(1)Hold the 2-stage changeover lever (C) so that the load lever (B) contacts the full load stopper. (When the load lever is equipped with a cancel mechanism, move it so that it contacts the stopper without canceling.)

(2)In this condition, confirm that the speed lever (A) moves from idle to full speed.

----------

----------

----------

----------

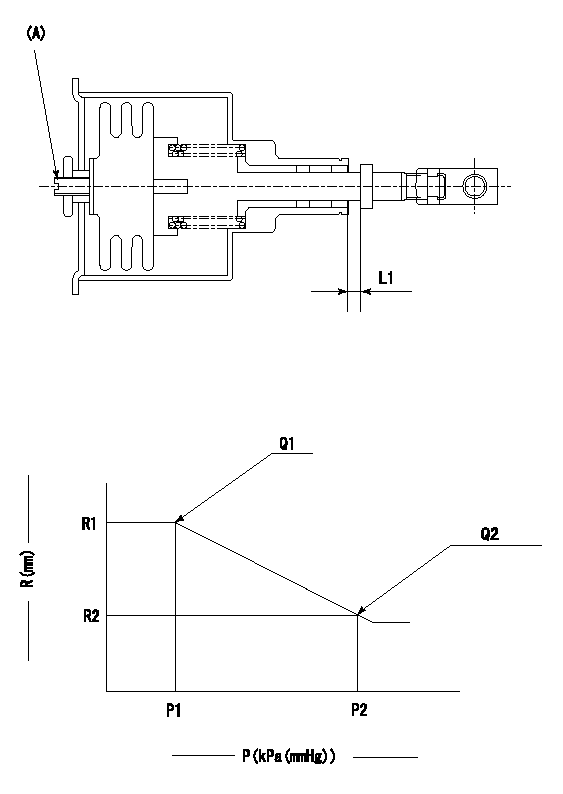

0000001601 ACS

(A) Set screw

1. Aneroid compensator unit adjustment

Screw in (A) to obtain L1.

2. Adjustment following governor installation

(1)Set the speed of the pump to N1 r/min and fix the control lever at the full set position.

(2)Screw in the aneroid compensator to obtain the performance shown in the graph above.

----------

N1=1000r/min L1=0.1~0.5mm

----------

R1=9.45mm R2=8.7mm P1=(84.2)kPa((632)mmHg) P2=64+-0.7kPa(480+-5mmHg) Q1=169.5+-3cm3/1000st Q2=(146)+-3cm3/1000st

----------

N1=1000r/min L1=0.1~0.5mm

----------

R1=9.45mm R2=8.7mm P1=(84.2)kPa((632)mmHg) P2=64+-0.7kPa(480+-5mmHg) Q1=169.5+-3cm3/1000st Q2=(146)+-3cm3/1000st

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(0deg)

----------

----------

a=(0deg)

Information:

Use of Cat Diesel Fuel System Cleaner or Cat Diesel Fuel System Conditioner does not lessen the responsibility of the engine owner and/or responsibility of the fuel supplier to follow all industry standard maintenance practices for fuel storage and for fuel handling. Refer to the “General Fuel Information” article in this Special Publication for additional information. Additionally, use of Cat Diesel Fuel System Cleaner or Cat Diesel Fuel System Conditioner does NOT lessen the responsibility of the owner of the engine to use appropriate diesel fuel. Refer to the “Fuel Specifications” section in this Special Publication (Maintenance Section) for guidance.

Caterpillar strongly recommends that Cat Diesel Fuel System Cleaner be used with biodiesel and biodiesel blends. Cat Diesel Fuel System Cleaner is suitable for use with biodiesel/biodiesel blends that meet Cat biodiesel recommendations and requirements. Note that not all fuel cleaners are suitable for use with biodiesel/biodiesel blends. Read and follow all applicable label usage instructions. Also, refer to this Special Publication, "Distillate Diesel Fuel", article and also refer to the “Biodiesel” article, which includes Cat biodiesel recommendations and requirements.When used as directed, Cat Diesel Fuel System Cleaner has proven to be compatible with non-road Tier 4 U.S. EPA certified engines that are equipped with aftertreatment devices.Note: When used as directed, Cat Diesel Fuel System Cleaner will not raise fuel sulfur levels measurably in the final fuel/additive blend. Follow all applicable national, regional, and local laws, mandates, and regulations concerning the use of diesel fuel conditioners/additives.

When used as directed Cat Diesel Fuel System Cleaner will not raise fuel sulfur levels measurably in the final fuel/additive blend. But, in the U.S., aftermarket fuel additives (retail consumer level versus bulk fuel additives used at the fuel supplier/distributor level) with more than 15 ppm sulfur are NOT allowed to be used in applications where ULSD usage is mandated (15 ppm or less fuel sulfur). Note that Cat Diesel Fuel System Cleaner contains less than 15 ppm of sulfur and is acceptable for use with ULSD fuel.

Renewable and Alternative Fuels

Renewable fuels are derived from renewable resources such as planted crops and crop residues (referred to as biomass), waste, algae, cellulosic material, yard and food waste, etc. Renewable fuels reduce the carbon footprint of the fuels compared to fossil fuels on a Life Cycle Analysis basis. Caterpillar, through sustainability initiatives, supports the development and use of renewable fuels.Renewable fuels (other than biodiesel) and alternative fuels (such as but not limited to Gas-to-Liquid fuel) are typically >99% hydrocarbons (composed of carbon and hydrogen). An exception is biodiesel, which is an oxygenated renewable fuel. Biodiesel is discussed in a separate article in this Fuel section. Significant research is on going to develop renewable fuels and produce the fuels economically.Caterpillar is not in a position to test all varieties of renewable and alternative fuels that are advertised in the market place. If a renewable or alternative fuel fulfills the performance requirements described in Cat Fuel Specification, the latest version of "ASTM D975", the latest version of "EN

Have questions with 106671-8882?

Group cross 106671-8882 ZEXEL

Hino

Hino

Hino

106671-8882

9 400 617 027

220801722B

INJECTION-PUMP ASSEMBLY

K13C-TK

K13C-TK