Information injection-pump assembly

ZEXEL

106671-8480

1066718480

HINO

220007520A

220007520a

Rating:

Service parts 106671-8480 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

23600-2221A

12.

Open Pre:MPa(Kqf/cm2)

14.7{150}/21.6{220}

14.

NOZZLE

Include in #1:

106671-8480

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

106671-8480

1066718480

HINO

220007520A

220007520a

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

134424-1420

Overflow valve opening pressure

kPa

162

147

177

Overflow valve opening pressure

kgf/cm2

1.65

1.5

1.8

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

4.6

4.54

4.6

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.75 60.25

Cal 1-4 deg. 60 59.75 60.25

Difference between angles 2

Cyl.1-2 deg. 120 119.75 120.25

Cyl.1-2 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cal 1-3 deg. 240 239.75 240.25

Cal 1-3 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-5 deg. 300 299.75 300.25

Cal 1-5 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

A

Rack position

7.2

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

141.4

138.4

144.4

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

7.5

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

149.7

147.7

151.7

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

7.7

Pump speed

r/min

1075

1075

1075

Average injection quantity

mm3/st.

155.8

152.8

158.8

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

D

Rack position

3.7+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

8.8

5.8

11.8

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_05

Adjusting point

F

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

160

160

180

Fixing the lever

*

Remarks

After startup boost setting

After startup boost setting

Timer adjustment

Pump speed

r/min

695--

Advance angle

deg.

0

0

0

Load

1/4

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

645

Advance angle

deg.

0.3

Load

1/4

Timer adjustment_03

Pump speed

r/min

850

Advance angle

deg.

1

0.7

1.3

Load

4/4

Timer adjustment_04

Pump speed

r/min

860+50

Advance angle

deg.

1

0.7

1.3

Load

3/4

Timer adjustment_05

Pump speed

r/min

1075-50

Advance angle

deg.

5.5

5.2

5.8

Load

4/4

Remarks

Finish

Finish

Test data Ex:

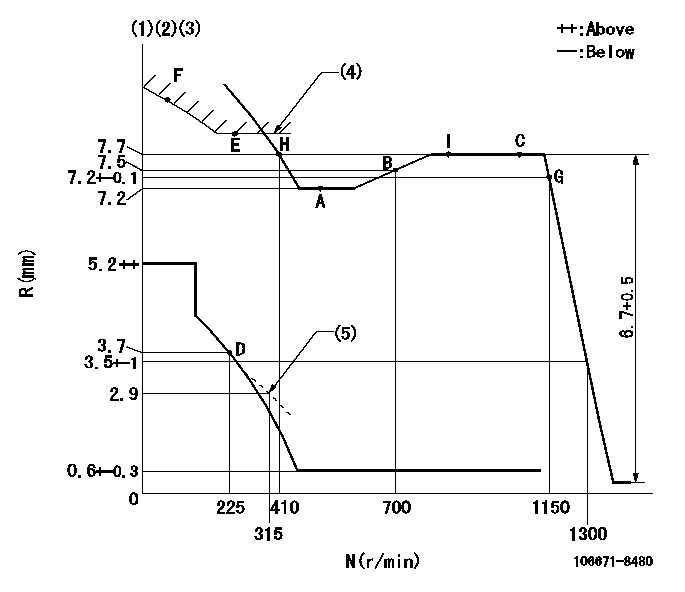

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Lever ratio: RT

(2)Target shim dimension: TH

(3)Tolerance for racks not indicated: +-0.05mm.

(4)Excess fuel setting for starting: SXL (N = N1)

(5)Damper spring setting

----------

RT=0.8 TH=2.8mm SXL=8+-0.1mm N1=350r/min

----------

----------

RT=0.8 TH=2.8mm SXL=8+-0.1mm N1=350r/min

----------

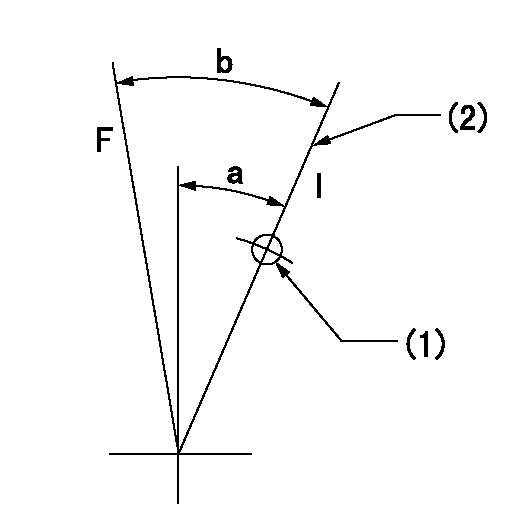

Speed control lever angle

F:Full speed

----------

----------

a=15deg+-5deg

----------

----------

a=15deg+-5deg

0000000901

F:Full load

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt setting

----------

aa=45mm

----------

a=24deg+-5deg b=35deg+-3deg

----------

aa=45mm

----------

a=24deg+-5deg b=35deg+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Set stopper screw so that rack position = aa (after setting, apply red paint).

----------

aa=13+-1mm

----------

a=47deg+-5deg b=33.5deg+-5deg

----------

aa=13+-1mm

----------

a=47deg+-5deg b=33.5deg+-5deg

0000001501 GOVERNOR TORQUE CONTROL

Dr:Torque control stroke

(A): Without torque control spring capsule

1. Adjustment procedures

(1)Procedure is the same as that for the RFD (former type), except that the positive torque control stroke must be determined at the full lever setting.

2. Procedures for adjustment

(1)Remove the torque control spring capsule.

(2)Operate the pump at approximately N1. (End of idling spring operation < N1.)

(3)Tilt the lever to the full side.

(4)Set so that R = RF.

(5)Increase the speed by pushing in the screw (attached to the bracket on the rear of the tension lever) through the adjusting window.

(6)Adjust so that the torque control stroke Dr1 can be obtained.

(7)Align N2 and N3 with the torque control spring capsule.

3. Final confirmation

(1)After final confirmation, temporarily set the load lever to N = N1, R = idling position.

(2)From this condition, increase speed to N = N4.

(3)Confirm that positive torque control stroke is Dr2.

----------

N1=500r/min N2=- N3=- N4=850r/min RF=7.2mm Dr1=0.5mm Dr2=0+0.3mm

----------

----------

N1=500r/min N2=- N3=- N4=850r/min RF=7.2mm Dr1=0.5mm Dr2=0+0.3mm

----------

0000001601 RACK SENSOR

(VR) measurement voltage

(I) Part number of the control unit

(G) Apply red paint.

(H): End surface of the pump

1. Rack sensor adjustment (-0620)

(1)Fix the speed control lever at the full position

(2)Set the speed to N1 r/min.

(If the boost compensator is provided, apply boost pressure.)

(3)Adjust the bobbin (A) so that the rack sensor's output voltage is VR+-0.01.

(4)At that time, rack position must be Ra.

(5)Apply G at two places.

Connecting part between the joint (B) and the nut (F)

Connecting part between the joint (B) and the end surface of the pump (H)

----------

N1=900r/min Ra=7.7mm

----------

----------

N1=900r/min Ra=7.7mm

----------

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(3deg)

----------

----------

a=(3deg)

Information:

Personal injury or death can result from machine articulation or movement. Machine frames can move and a person can be crushed. Connect the steering frame lock between the front and rear frames before working on the machine.Before operating the machine, place the steering frame lock in the stored position.Failure to place the steering frame lock into the stored position before operating can result in loss of steering.

Reference: Disassembly and Assembly, M0084637, "R1700 Load Haul Dump Machine Systems"Reference: Disassembly and Assembly, M0100022, "R2900 Load Haul Dump Machine Systems"Required Parts

Table 1

Required Parts

Qty Part Number Description

1 389-9442 Insulation

1 434-1304 Insulation

1 434-1305 Insulation

7 290-1993 Cable Strap Machine Preparation

Note: Cleanliness is an important factor. Before the removal procedure, clean the exterior of the component thoroughly. Cleaning the exterior will help to prevent dirt from entering the internal mechanism.

Move the machine to a hard level surface away from operating machines and away from personnel.

Engage the parking brake. Place wheel blocks in front of the wheels and behind the wheels.

Stop the engine.

Install the steering frame lock. Refer to Disassembly and Assembly, "Steering Frame Lock - Install".

Turn the key start switch and the battery disconnect switch to the OFF position. If there is no battery disconnect switch, remove the negative battery cable at the battery.

Release system pressure. Refer to Operation and Maintenance Manual, "System Pressure - Release".Procedure

Illustration 1 g06525155

Typical example

(1) Cover As

(2) Cover As

Remove cover assembly (1) and cover assembly (2).

Illustration 2 g06525163

Typical example

(3) Hose As

Locate DEF supply hose assembly (3).

Illustration 3 g06526653

DEF supply hose on the R1700 machine

(4) 290-1993 Cable Strap

(5) 389-9442 Insulation

(6) 434-1305 Insulation

(7) 434-1304 Insulation

Illustration 4 g06526655

DEF supply hose on the R2900 machine

(4) 290-1993 Cable Strap

(5) 389-9442 Insulation

(6) 434-1305 Insulation

(7) 434-1304 Insulation

Install Item (5) through Item (7), securing with 290-1993 Cable Straps as required.Note: On the R1700 machine, 434-1305 Insulation (6) is installed over the top of 389-9442 Insulation (5).Note: On the R2900 machine, 434-1305 Insulation (6) slightly overlaps 389-9442 Insulation (5).

Install cover assembly (1) and cover assembly (2). Refer to Illustration 1.