Information injection-pump assembly

ZEXEL

106671-8401

1066718401

HINO

220007071A

220007071a

Rating:

Cross reference number

ZEXEL

106671-8401

1066718401

HINO

220007071A

220007071a

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

134424-1720

Overflow valve opening pressure

kPa

162

147

177

Overflow valve opening pressure

kgf/cm2

1.65

1.5

1.8

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

4.4

4.34

4.4

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.75 60.25

Cal 1-4 deg. 60 59.75 60.25

Difference between angles 2

Cyl.1-2 deg. 120 119.75 120.25

Cyl.1-2 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cal 1-3 deg. 240 239.75 240.25

Cal 1-3 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-5 deg. 300 299.75 300.25

Cal 1-5 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

A

Rack position

9.2

Pump speed

r/min

650

650

650

Average injection quantity

mm3/st.

185

183

187

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Boost pressure

kPa

32

32

Boost pressure

mmHg

240

240

Injection quantity adjustment_02

Adjusting point

B

Rack position

9.2

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

190.5

184.5

196.5

Max. variation between cylinders

%

0

-5

5

Fixing the lever

*

Boost pressure

kPa

32

32

Boost pressure

mmHg

240

240

Injection quantity adjustment_03

Adjusting point

D

Rack position

4.2+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

12.5

9.5

15.5

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_04

Adjusting point

E

Rack position

6.95

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

131.5

129.5

133.5

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

650

650

650

Rack position

6.95

Boost pressure

kPa

3.3

3.3

5.3

Boost pressure

mmHg

25

25

40

Boost compensator adjustment_02

Pump speed

r/min

650

650

650

Rack position

9.2

Boost pressure

kPa

18.7

18.7

18.7

Boost pressure

mmHg

140

140

140

Timer adjustment

Pump speed

r/min

700--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

650

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1000

Advance angle

deg.

3

2.7

3.3

Remarks

Finish

Finish

Test data Ex:

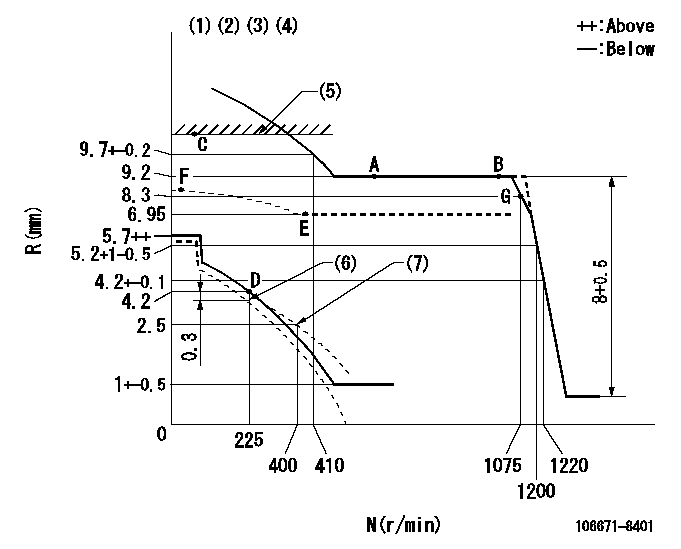

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Lever ratio: RT

(2)Target shim dimension: TH

(3)Tolerance for racks not indicated: +-0.05mm.

(4)Deliver with positive torque control spring not operating

(5)RACK LIMIT

(6)Set idle at delivery

(7)Damper spring setting

----------

RT=0.8 TH=2.2mm

----------

----------

RT=0.8 TH=2.2mm

----------

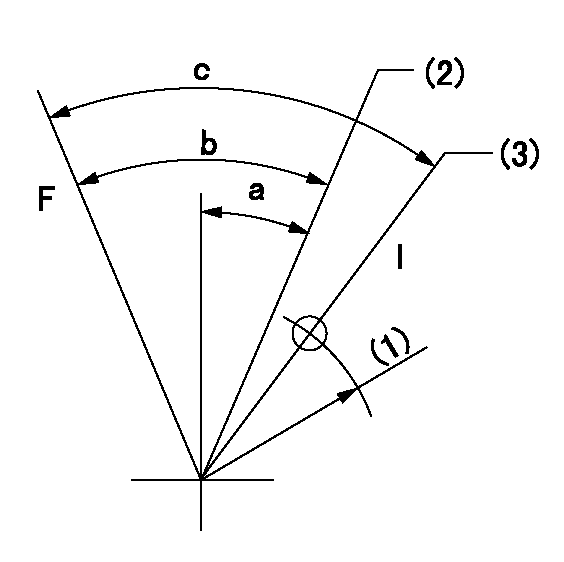

Speed control lever angle

F:Full speed

----------

----------

a=14.5deg+-5deg

----------

----------

a=14.5deg+-5deg

0000000901

F:Full load

I:Idle

(1)R = aa

(2)Set point D

(3)At delivery

----------

aa=45mm

----------

a=25deg+-5deg b=44deg+-3deg c=46deg+-5deg

----------

aa=45mm

----------

a=25deg+-5deg b=44deg+-3deg c=46deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Set stopper screw so that rack position = aa (after setting, apply red paint).

----------

aa=12+-0.1mm

----------

a=39deg+-5deg b=35deg+-5deg

----------

aa=12+-0.1mm

----------

a=39deg+-5deg b=35deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(1deg)

----------

----------

a=(1deg)

Information:

Unit Injector Mechanism

Illustration 2 g01430766

Typical unit injector mechanism (17) Unit injector (18) Adjusting nut (19) Rocker arm assembly (20) CamshaftThe unit injector mechanism provides the downward force that is required to pressurize the fuel in the unit injector. When a signal is received from the ECM, the unit injector (17) injects the pressurized fuel into the combustion chamber. The camshaft gear is driven by an idler gear which is driven through the front gear train by the crankshaft gear. The gears of the front gear train that are timed must be aligned in order to provide the correct relationship between the piston and valve movement. During assembly of the front gear train, care must be taken in order to correctly align the timing marks of the gears. The camshaft has three camshaft lobes for each cylinder. Two lobes operate the inlet and exhaust valves, and one operates the unit injector mechanism. Force is transferred from the unit injector lobe on camshaft (20) through rocker arm assembly (19) to the top of the unit injector. The adjusting nut (18) allows setting of the unit injector adjustment. Refer to the Testing and Adjusting, "Electronic Unit Injector - Adjust" for the proper setting of the unit injector.Unit Injector

Illustration 3 g01332439

(21) Solenoid (22) Tappet (23) Plunger (24) Barrel (25) Nozzle assemblyOperation of the Electronic Unit Injector

The operation of the Electronic Control Unit (EUI) consists of the following four stages: Pre-injection, Injection, End of injection and Fill. Unit injectors use a plunger and barrel to pump high pressure fuel into the combustion chamber. Components of the injector include the tappet, the plunger, the barrel and nozzle assembly. Components of the nozzle assembly include the spring, the nozzle check, and a nozzle tip. The cartridge valve is made up of the following components: solenoid, armature, poppet valve and poppet spring.The injector is mounted in an injector bore in the cylinder head which has an integral fuel supply passage. The injector sleeve separates the injector from the engine coolant in the water jacket. Some engines use a stainless steel sleeve. The stainless steel sleeve fits into the cylinder head with a light press fit.

Illustration 4 g00942799

Pre-injection (A) Fuel supply pressure (B) Injection pressure (C) Moving parts (D) Mechanical movement (E) Fuel movement.Pre-injection metering starts with the injector plunger and the injector tappet at the top of the fuel injection stroke. When the plunger cavity is full of fuel, the poppet valve is in the open position and the nozzle check is in the open position. Fuel leaves the plunger cavity when the rocker arm pushes down on the tappet and the plunger. Fuel flow that is blocked by the closed nozzle check valve flows past the open poppet valve to the fuel supply passage in the cylinder head. If the solenoid is energized, the poppet valve remains open and the fuel from the plunger cavity continues flowing into the fuel supply passage.

Illustration 5 g00942798

Injection (A) Fuel supply pressure. (B) Injection pressure (C) Moving parts (D) Mechanical movement (E)

Illustration 2 g01430766

Typical unit injector mechanism (17) Unit injector (18) Adjusting nut (19) Rocker arm assembly (20) CamshaftThe unit injector mechanism provides the downward force that is required to pressurize the fuel in the unit injector. When a signal is received from the ECM, the unit injector (17) injects the pressurized fuel into the combustion chamber. The camshaft gear is driven by an idler gear which is driven through the front gear train by the crankshaft gear. The gears of the front gear train that are timed must be aligned in order to provide the correct relationship between the piston and valve movement. During assembly of the front gear train, care must be taken in order to correctly align the timing marks of the gears. The camshaft has three camshaft lobes for each cylinder. Two lobes operate the inlet and exhaust valves, and one operates the unit injector mechanism. Force is transferred from the unit injector lobe on camshaft (20) through rocker arm assembly (19) to the top of the unit injector. The adjusting nut (18) allows setting of the unit injector adjustment. Refer to the Testing and Adjusting, "Electronic Unit Injector - Adjust" for the proper setting of the unit injector.Unit Injector

Illustration 3 g01332439

(21) Solenoid (22) Tappet (23) Plunger (24) Barrel (25) Nozzle assemblyOperation of the Electronic Unit Injector

The operation of the Electronic Control Unit (EUI) consists of the following four stages: Pre-injection, Injection, End of injection and Fill. Unit injectors use a plunger and barrel to pump high pressure fuel into the combustion chamber. Components of the injector include the tappet, the plunger, the barrel and nozzle assembly. Components of the nozzle assembly include the spring, the nozzle check, and a nozzle tip. The cartridge valve is made up of the following components: solenoid, armature, poppet valve and poppet spring.The injector is mounted in an injector bore in the cylinder head which has an integral fuel supply passage. The injector sleeve separates the injector from the engine coolant in the water jacket. Some engines use a stainless steel sleeve. The stainless steel sleeve fits into the cylinder head with a light press fit.

Illustration 4 g00942799

Pre-injection (A) Fuel supply pressure (B) Injection pressure (C) Moving parts (D) Mechanical movement (E) Fuel movement.Pre-injection metering starts with the injector plunger and the injector tappet at the top of the fuel injection stroke. When the plunger cavity is full of fuel, the poppet valve is in the open position and the nozzle check is in the open position. Fuel leaves the plunger cavity when the rocker arm pushes down on the tappet and the plunger. Fuel flow that is blocked by the closed nozzle check valve flows past the open poppet valve to the fuel supply passage in the cylinder head. If the solenoid is energized, the poppet valve remains open and the fuel from the plunger cavity continues flowing into the fuel supply passage.

Illustration 5 g00942798

Injection (A) Fuel supply pressure. (B) Injection pressure (C) Moving parts (D) Mechanical movement (E)