Information injection-pump assembly

BOSCH

9 400 616 983

9400616983

ZEXEL

106671-8260

1066718260

HINO

220203510A

220203510a

Rating:

Cross reference number

BOSCH

9 400 616 983

9400616983

ZEXEL

106671-8260

1066718260

HINO

220203510A

220203510a

Zexel num

Bosch num

Firm num

Name

106671-8260

9 400 616 983

220203510A HINO

INJECTION-PUMP ASSEMBLY

EK100 K

EK100 K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

134424-0920

Overflow valve opening pressure

kPa

162

147

177

Overflow valve opening pressure

kgf/cm2

1.65

1.5

1.8

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.3

3.2

3.3

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

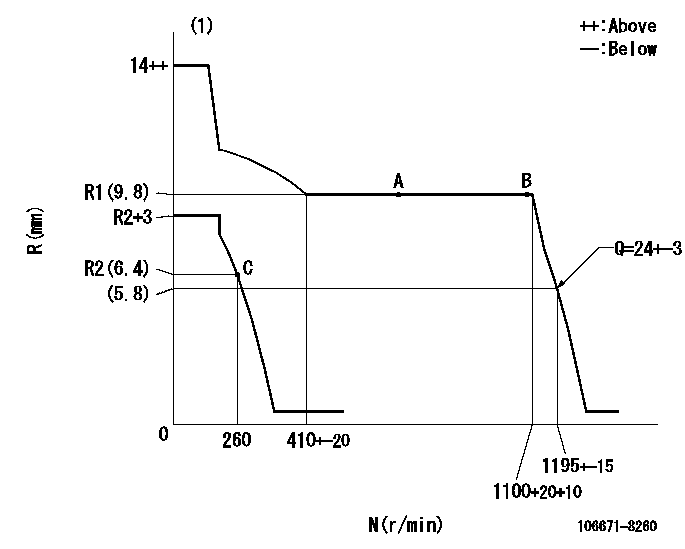

Injection quantity adjustment

Adjusting point

A

Rack position

R1(9.8)

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

130

128

132

Max. variation between cylinders

%

0

-4

4

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

R2(6.4)

Pump speed

r/min

260

260

260

Average injection quantity

mm3/st.

16

13

19

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Timer adjustment

Pump speed

r/min

750--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

700

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1100

Advance angle

deg.

3.6

3.1

4.1

Timer adjustment_04

Pump speed

r/min

-

Advance angle

deg.

4

4

4

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

----------

K=15

----------

----------

K=15

----------

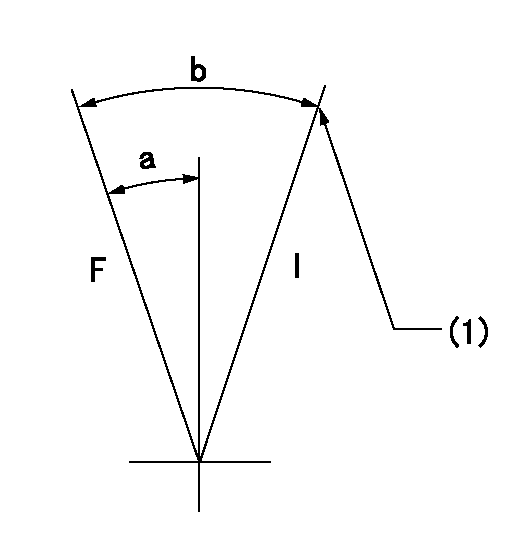

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=(17deg)+-5deg b=(31deg)+-5deg

----------

----------

a=(17deg)+-5deg b=(31deg)+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=27deg+-5deg b=53deg+-5deg

----------

----------

a=27deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(0deg)

----------

----------

a=(0deg)

Information:

Table 1

Required Parts

Item Qty Part Number Description Former Part Number

1 1 560-4252 Bracket 431-8663

2 1 396-3862 (1) Control Harness As 396-3862 (1)

524-5527 (2) Control Harness As 524-5527 (2)

3 1 471-4176 Hose As 380-9241

4 - 7K-1181 Cable Strap NA

5 - 3E-6909 Clip NA

(1) FMC 1 - 772 (Not Equipped with DEF Quality Sensor)

(2) FMC 773 - Up (Equipped with DEF Quality Sensor)Note: These parts should be ordered and replaced only if there is evidence of damage to any part.Rework Procedure

Park the machine on level ground, lower all implements to the ground, shut off machine, and relieve all hydraulic system pressure.

Read and understand this Rework Procedure before starting work.

Illustration 1 g06340431

General location and reference Views

DEF tank cover not shown for clarity.

(A) Fuel tank

(B) Diesel Exhaust Fluid (DEF) module group

See Illustration for the general location of the DEF Module Group and reference views that will be used in future steps.

Illustration 2 g06340436

Location of hardware.

(C) Hardware

(D) DEF fill hose

(E) Clamp

Inspect control harness assembly (2) at location (AA) and hose assembly (3) at location (BB) for rubbing and or fouling on the DEF Tank Cover. If either item is damaged, replace the damaged part.Note: Hardware (C) holding the DEF Module Group to the fuel tank and clamp (E) holding DEF Fill Hose (D) to the tank will need to be loosened to reposition the DEF Module Group to access control harness assembly (2) and hose assembly (3).

After control harness assembly (2) and hose assembly (3) have been inspected and found without damage OR replaced, secure both parts using Steps 6 through 9.

Illustration 3 g06340441

Left view

Fuel tank not shown.

(F) Diesel exhaust fluid module

Illustration 4 g06340446

Location CC

(G) Harness bundled to avoid fouling

Illustration 5 g06340447

Location DD

(H) Terminating resistor

Secure control harness assembly (2) and hose assembly (3) to left side of DEF Module using tie straps (4).Reference: Refer to Illustrations 3, 4, and 5.Note: At location (CC), use tie straps to secure harness bundles to prevent harness from contacting the fuel tank. (See Illustration 4).Note: At location (DD), use tie straps (4) to secure control harness assembly (2) and hose assembly (3), and terminating resistor (H) at lower location. (See Illustration 5).

Illustration 6 g06340448

Location of hardware

(C) Hardware

(E) Clamp

Reposition the DEF Module Group, install bracket (1), and reinstall the remaining hardware (C), clamp (E) removed in Step 4. Check to make sure control harness assembly (2) and hose assembly (3) will not

Have questions with 106671-8260?

Group cross 106671-8260 ZEXEL

Hino

106671-8260

9 400 616 983

220203510A

INJECTION-PUMP ASSEMBLY

EK100

EK100