Information injection-pump assembly

ZEXEL

106671-8132

1066718132

HINO

220203163A

220203163a

Rating:

Cross reference number

ZEXEL

106671-8132

1066718132

HINO

220203163A

220203163a

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve (drive side)

134424-2020

Overflow valve opening pressure (drive side)

kPa

162

147

177

Overflow valve opening pressure (drive side)

kgf/cm2

1.65

1.5

1.8

Overflow valve (governor side)

134424-2120

Overflow valve opening pressure (governor side)

kPa

162

147

177

Overflow valve opening pressure (governor side)

kgf/cm2

1.65

1.5

1.8

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

4.1

4.04

4.1

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.75 60.25

Cal 1-4 deg. 60 59.75 60.25

Difference between angles 2

Cyl.1-2 deg. 120 119.75 120.25

Cyl.1-2 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cal 1-3 deg. 240 239.75 240.25

Cal 1-3 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-5 deg. 300 299.75 300.25

Cal 1-5 deg. 300 299.75 300.25

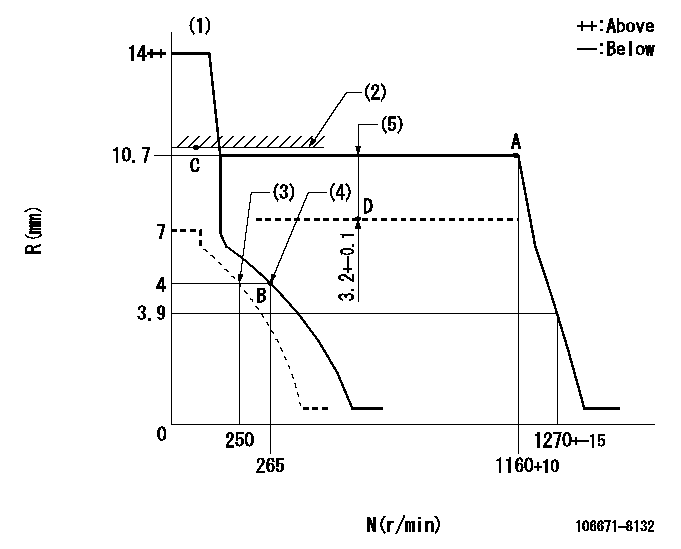

Injection quantity adjustment

Adjusting point

A

Rack position

10.7

Pump speed

r/min

1160

1160

1160

Average injection quantity

mm3/st.

179.5

177.5

181.5

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Boost pressure

kPa

90.6

90.6

Boost pressure

mmHg

680

680

Injection quantity adjustment_02

Adjusting point

B

Rack position

4+-0.5

Pump speed

r/min

265

265

265

Average injection quantity

mm3/st.

12.5

11

14

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

500

500

500

Rack position

R1-3.2

Boost pressure

kPa

20

17.3

22.7

Boost pressure

mmHg

150

130

170

Boost compensator adjustment_02

Pump speed

r/min

500

500

500

Rack position

R1(10.7)

Boost pressure

kPa

80

76

84

Boost pressure

mmHg

600

570

630

Timer adjustment

Pump speed

r/min

975--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

925

Advance angle

deg.

0.3

Timer adjustment_03

Pump speed

r/min

1150

Advance angle

deg.

2.5

2.2

2.8

Remarks

Finish

Finish

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Boost compensator excessive fuel lever at operation: L1

(3)Set idle sub-spring

(4)Main spring setting

(5)Boost compensator stroke

----------

K=10 L1=10.7+0.2mm

----------

----------

K=10 L1=10.7+0.2mm

----------

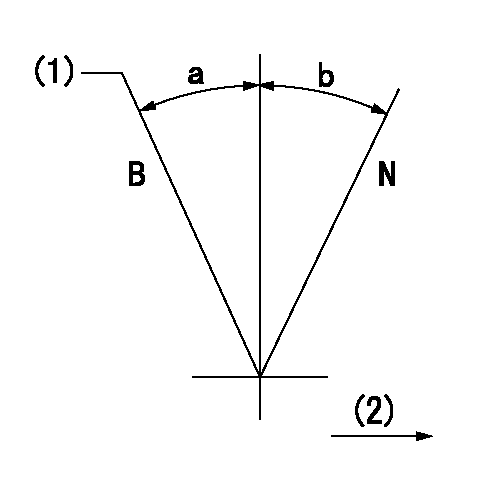

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=(10deg)+-5deg b=(31deg)+-5deg

----------

----------

a=(10deg)+-5deg b=(31deg)+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=27deg+-5deg b=53deg+-5deg

----------

----------

a=27deg+-5deg b=53deg+-5deg

0000001101

N:Normal

B:When boosted

(1)Rack position = aa

(2)Drive side

----------

aa=10.7+0.2mm

----------

a=(15deg) b=(15deg)

----------

aa=10.7+0.2mm

----------

a=(15deg) b=(15deg)

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(40deg)

----------

----------

a=(40deg)

Information:

Operation Description:Power to the ECM can fail due to an open circuit in the wire, or a blown fuse. A fuse is blown out as a result of an overloaded circuit. For example, the +battery connection is shorted to ground.Test Step 1. CHECK THE ECM FOR POWER AND GROUND.At the ECM, measure the voltage from contact 1 to contact 2. Expected Result:The voltage is system voltage.Results:

OK - The voltage is system voltage. The power supply circuit to the ECM is correct. STOP

NOT OK - The voltage is not system voltage. Proceed to Test Step 2.Test Step 2. CHECK THE FUSEWhenever the machine's electronic components fail to function, check the appropriate fuse for the ECM.

Check the fuse for the ECM.Expected Result:The fuse is correct.Results:

YES - The fuse is correct. Proceed to Test Step 3.

NO - The fuse is not correct.Repair: Replace the blown fuse or reset the circuit breaker. Observe the machine for a recurrence of the problem. If the problem persists, the reason for the blown fuse must be isolated and corrected.STOPTest Step 3. CHECK THE POWER WIRE TO THE ECM.

Turn the key start switch and the disconnect switch to the OFF position.

At the fuse, connect the lead from the multimeter to wire 113-RD.

At the ECM, connect the other lead from the multimeter to connector contact 1 and measure the resistance.Expected Result:The resistance is less than 5 ohms.Results:

OK - The resistance is less than 5 ohms. The wiring circuit is correct. Proceed to Test Step 4.

NOT OK - The resistance measurement is greater than 5000 ohms. The wiring has an open circuit.Repair: Repair the wiring harness or replace the wiring harness. STOPTest Step 4. CHECK THE ECM GROUND CONNECTIONS.

The keyswitch and the disconnect switch remain in the OFF position.

At the ECM, measure the resistance from connector contact 2 to frame ground.Expected Result:The resistance is less than 5 ohms.Results:

OK - The resistance is less than 5 ohms. The ground circuit is correct. The ECM may have failed. This is unlikely. Perform this entire procedure again. If the problem remains, the ECM may need to be replaced. Contact your dealerships for possible consultation with Caterpillar. This consultation may greatly reduce repair time.STOP

NOT OK - The resistance is greater than 5000 ohms. The ground circuit has failed.Repair: The ground circuit has failed. Repair the wiring harness or replace the wiring harness.STOP

OK - The voltage is system voltage. The power supply circuit to the ECM is correct. STOP

NOT OK - The voltage is not system voltage. Proceed to Test Step 2.Test Step 2. CHECK THE FUSEWhenever the machine's electronic components fail to function, check the appropriate fuse for the ECM.

Check the fuse for the ECM.Expected Result:The fuse is correct.Results:

YES - The fuse is correct. Proceed to Test Step 3.

NO - The fuse is not correct.Repair: Replace the blown fuse or reset the circuit breaker. Observe the machine for a recurrence of the problem. If the problem persists, the reason for the blown fuse must be isolated and corrected.STOPTest Step 3. CHECK THE POWER WIRE TO THE ECM.

Turn the key start switch and the disconnect switch to the OFF position.

At the fuse, connect the lead from the multimeter to wire 113-RD.

At the ECM, connect the other lead from the multimeter to connector contact 1 and measure the resistance.Expected Result:The resistance is less than 5 ohms.Results:

OK - The resistance is less than 5 ohms. The wiring circuit is correct. Proceed to Test Step 4.

NOT OK - The resistance measurement is greater than 5000 ohms. The wiring has an open circuit.Repair: Repair the wiring harness or replace the wiring harness. STOPTest Step 4. CHECK THE ECM GROUND CONNECTIONS.

The keyswitch and the disconnect switch remain in the OFF position.

At the ECM, measure the resistance from connector contact 2 to frame ground.Expected Result:The resistance is less than 5 ohms.Results:

OK - The resistance is less than 5 ohms. The ground circuit is correct. The ECM may have failed. This is unlikely. Perform this entire procedure again. If the problem remains, the ECM may need to be replaced. Contact your dealerships for possible consultation with Caterpillar. This consultation may greatly reduce repair time.STOP

NOT OK - The resistance is greater than 5000 ohms. The ground circuit has failed.Repair: The ground circuit has failed. Repair the wiring harness or replace the wiring harness.STOP