Information injection-pump assembly

ZEXEL

106671-8130

1066718130

HINO

220203161A

220203161a

Rating:

Cross reference number

ZEXEL

106671-8130

1066718130

HINO

220203161A

220203161a

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve (drive side)

134424-2020

Overflow valve opening pressure (drive side)

kPa

162

147

177

Overflow valve opening pressure (drive side)

kgf/cm2

1.65

1.5

1.8

Overflow valve (governor side)

134424-2120

Overflow valve opening pressure (governor side)

kPa

162

147

177

Overflow valve opening pressure (governor side)

kgf/cm2

1.65

1.5

1.8

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

4.1

4.04

4.1

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.75 60.25

Cal 1-4 deg. 60 59.75 60.25

Difference between angles 2

Cyl.1-2 deg. 120 119.75 120.25

Cyl.1-2 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cal 1-3 deg. 240 239.75 240.25

Cal 1-3 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-5 deg. 300 299.75 300.25

Cal 1-5 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

A

Rack position

10.5

Pump speed

r/min

1160

1160

1160

Average injection quantity

mm3/st.

188.4

186.4

190.4

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Boost pressure

kPa

58.7

58.7

Boost pressure

mmHg

440

440

Injection quantity adjustment_02

Adjusting point

B

Rack position

4.1+-0.5

Pump speed

r/min

265

265

265

Average injection quantity

mm3/st.

13.6

12.1

15.1

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

500

500

500

Rack position

R1-3.9

Boost pressure

kPa

21.3

18.6

24

Boost pressure

mmHg

160

140

180

Boost compensator adjustment_02

Pump speed

r/min

500

500

500

Rack position

R1(10.5)

Boost pressure

kPa

45.3

45.3

45.3

Boost pressure

mmHg

340

340

340

Timer adjustment

Pump speed

r/min

975--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

925

Advance angle

deg.

0.3

Timer adjustment_03

Pump speed

r/min

1150

Advance angle

deg.

2.5

2.2

2.8

Remarks

Finish

Finish

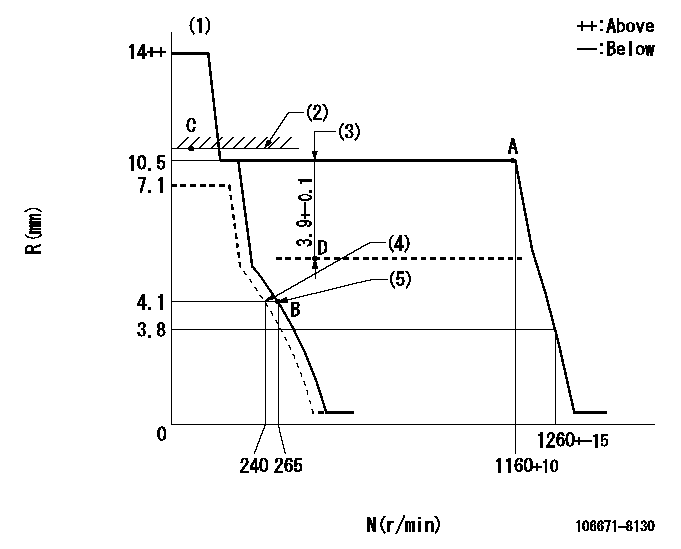

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Boost compensator excessive fuel lever at operation: L1

(3)Boost compensator stroke

(4)Set idle sub-spring

(5)Main spring setting

----------

K=8 L1=10.5+0.2mm

----------

----------

K=8 L1=10.5+0.2mm

----------

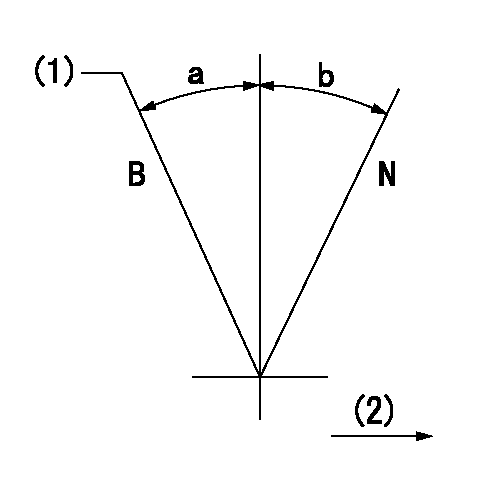

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=8deg+-5deg b=31deg+-5deg

----------

----------

a=8deg+-5deg b=31deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=27deg+-5deg b=53deg+-5deg

----------

----------

a=27deg+-5deg b=53deg+-5deg

0000001101

N:Normal

B:When boosted

(1)Rack position = aa

(2)Drive side

----------

aa=R1(10.5)+0.2mm

----------

a=(15deg) b=(15deg)

----------

aa=R1(10.5)+0.2mm

----------

a=(15deg) b=(15deg)

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(40deg)

----------

----------

a=(40deg)

Information:

Illustration 1 g01339995

Over Temperature Alarm

The Over Temperature alarm monitors the particulate filter temperature and the over temperature alarm produces an alarm if the temperature exceeds a configurable threshold. The operator is informed of an Over Temperature Alarm. The Over-Temperature Warning alarm is set to the "ON" state when the monitored temperature reaches or exceeds the Assert Alarm temperature value as configured by the user through the monitoring system. Pin 59 in the "ON" state will illuminate the optional Over-Temperature LED. Refer Systems Operation Troubleshooting, Testing and Adjusting, KENR6695-00, "Input Components".Through the CAT ET service tool, the users may configure the conditions to reset the Over-Temperature Warning alarm to "OFF" by choosing one of two methods:

The Over-Temperature Warning alarm will automatically be set to the "OFF" state when the monitored temperature drops below the Assert Alarm temperature value.

The Over-Temperature Warning alarm will stay latched in the "ON" state until cleared by the user through Cat ET.Over-Pressure Alarm

The Over-Pressure Alarm monitors the particulate filter pressure and annunciates an alarm if the pressure exeeds a configurable threshold. The operator should be informed of an Over-Pressure Alarm. There are two configurable Over-Pressure Alarm sets of conditions. By programming the two configurable Over-Pressure Alarm sets differently, one may be considered a Warning alarm and the other as a Critical alarm. The Warning alarm will be associated with Pin 60 (the optional Over-Pressure LED) and the Critical alarm will be associated with Pin 61 (the optional System Problem LED).

The Warning alarm is associated with the Over-Pressure LED.

The Critical alarm is associated with the System Problem LED.Refer Systems Operation Troubleshooting, Testing and Adjusting, KENR6695-00, "Input Components"Conditions To Set The Over-Pressure Alarm To The "ON" State

When the pressure exceeds the Pressure Threshold for the programmed percent of time (Duty Cycle) over the Time Interval, then the appropriate alarm (Over-Pressure or System Problem) is set to "ON". The pressure is sampled in 1 second intervals.Conditions To Set The Over-Pressure Alarm To The "OFF" State

The user may configure the conditions to reset the Over-Pressure alarms to "OFF" by choosing one of two methods:

The Over-Pressure alarm is set to the "OFF" state when the "ON" conditions are no longer met.

The Over-Pressure alarm will stay latched in the "ON" state until the Logged Event is cleared by the user through Cat ET.Configurable Parameters - The following parameters are configurable through the CAT ET service tool,

Particulate Trap Over-Pressure Warning Activation Time Percentage – Default is 10%

Particulate Trap Over-Pressure Warning Alarm Reset Configuration – Default is Manual

Particulate Trap Over-Pressure Critical Alarm Activation Time Percentage – Default is 10%Programmable Monitoring System

The purpose of the programmable monitoring system is to give the customers the ability to customize how the system reacts to possible engine damaging conditions. This feature reduces the number of custom personality modules, and part numbers, needed to meet widely varying customer needs. CAT ET can be used to view Programmable Monitoring System settings and customize the Programmable Monitoring System if allowed via security settings. Table 1 describes the programmable monitoring system. In