Information injection-pump assembly

BOSCH

9 400 616 974

9400616974

ZEXEL

106671-8100

1066718100

HINO

220005980A

220005980a

Rating:

Service parts 106671-8100 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

23600-1221C

12.

Open Pre:MPa(Kqf/cm2)

21.6{220}

15.

NOZZLE SET

Include in #1:

106671-8100

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 616 974

9400616974

ZEXEL

106671-8100

1066718100

HINO

220005980A

220005980a

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SEAJ967d}

1404 Test oil ISO4113 or {SEAJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

134424-0920

Overflow valve opening pressure

kPa

162

147

177

Overflow valve opening pressure

kgf/cm2

1.65

1.5

1.8

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.3

3.24

3.3

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.75 60.25

Cal 1-4 deg. 60 59.75 60.25

Difference between angles 2

Cyl.1-2 deg. 120 119.75 120.25

Cyl.1-2 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cal 1-3 deg. 240 239.75 240.25

Cal 1-3 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-5 deg. 300 299.75 300.25

Cal 1-5 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

A

Rack position

9.9

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

125.5

122.5

128.5

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

10.5

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

141.2

139.2

143.2

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

10.9

Pump speed

r/min

1150

1150

1150

Average injection quantity

mm3/st.

149.7

146.7

152.7

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

D

Rack position

7+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

16

13

19

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_05

Adjusting point

E

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

135

135

155

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

950

Advance angle

deg.

0.5

Timer adjustment_02

Pump speed

r/min

1000

Advance angle

deg.

1.5

Timer adjustment_03

Pump speed

r/min

1050

Advance angle

deg.

1.9

1.4

2.4

Timer adjustment_04

Pump speed

r/min

1150

Advance angle

deg.

4.5

4.2

4.8

Remarks

Finish

Finish

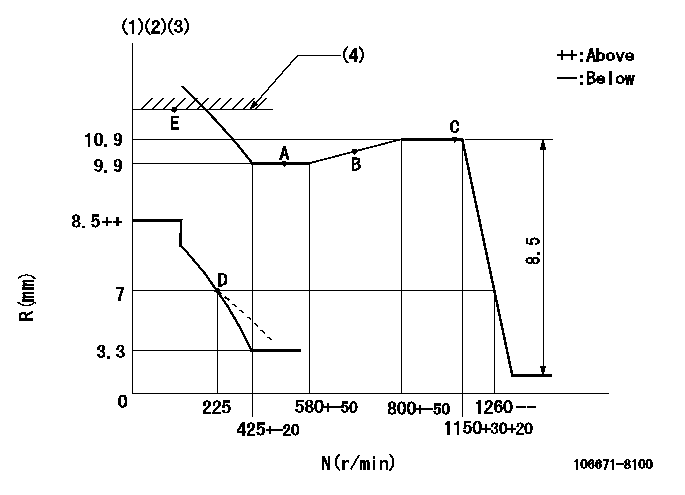

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Lever ratio: RT

(2)Target shim dimension: TH

(3)Damper spring setting: DL

(4)RACK LIMIT

----------

RT=1 TH=1.8mm DL=6.2-0.2mm

----------

----------

RT=1 TH=1.8mm DL=6.2-0.2mm

----------

Speed control lever angle

F:Full speed

----------

----------

a=15deg+-5deg

----------

----------

a=15deg+-5deg

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=10deg+-5deg b=25deg+-3deg

----------

----------

a=10deg+-5deg b=25deg+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=15deg+-5deg b=64deg+-5deg

----------

----------

a=15deg+-5deg b=64deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(0deg)

----------

----------

a=(0deg)

Information:

Illustration 1 g00280782

Connections for the Electronic Technician (ET)The components that are needed in order to use the CAT Electronic Technician in order to determine diagnostic codes are listed: (1) An IBM-COMPATIBLE personal computer with an installed current version of Caterpillar Electronic Technician software (2) 139-4166 Data Link Cable or 7X-1570 Data Link Cable (3) 7X-1425 Cable and 4C-6805 Adapter (4) Special Publication, JEBD3003, Special Publication, JERD2124, Special Publication, JERD2129 ; Caterpillar Electronic Technician software (5) 7X-1700 Communication Adapter Tool with Special Publication, NEXG4323, "Communications Adapter Software"

Illustration 2 g00774942

Connections for the Communication Adapter II and the Electronic Technician (ET)The components that are needed in order to use the Communication Adapter II and the CAT Electronic Technician in order to determine diagnostic codes are listed: (6) Cable (7) 171-4400 Communication Adapter ii (8) Service diagnostic cable. (9) Current version of Caterpillar Electronic Technician software and an IBM-COMPATIBLE personal computerReferenceSee Special Publication, NEHS0758, "Communications Adapter II User's Manual Contains Software".Note: Caterpillar Electronic Technician (ET) is a software program that can be used on an IBM compatible personal computer. In order to use the Caterpillar Electronic Technician (ET), order the following materials: Special Publication, JERD2124, "ET Single Use Program License", Special Publication, JEHP1026, "Information and Requirements Sheet", 7X-1425 Data Link Cable and the Data Subscription and Special Publication, JERD2142, "Data Subscription". The Special Publication, JEHP1026, "Information and Requirements Sheet" lists the required hardware and the features of the ET.The Electronic Technician (ET) is not required in order to determine the diagnostic codes and the ET is not required in order to clear the diagnostic codes. However, the process of determining the diagnostic codes is easier and faster by using the ET. The ET can also display information on the history of a diagnostic code and the parameter status of diagnostic codes. These features allow the ET to be a useful tool for troubleshooting.The Electronic Technician (ET) is used to communicate to the electronic control module over the data link by connecting to the machine diagnostic connector. The diagnostic connector is located by the circuit breaker panel. For more information and the locations of the connectors, see Troubleshooting, "Electrical Components and Connector Locations" and the Electrical System Schematic in your machine's Service Manual.Connect the ET to the machine. Turn the key start switch to the RUN position. Start the ET. The ET will initiate communications with the electronic control modules on the machine. The ET will list the available electronic control modules on the machine after communication has been established.