Information injection-pump assembly

BOSCH

9 400 619 662

9400619662

ZEXEL

106671-8080

1066718080

Rating:

Cross reference number

BOSCH

9 400 619 662

9400619662

ZEXEL

106671-8080

1066718080

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

134424-1420

Overflow valve opening pressure

kPa

162

147

177

Overflow valve opening pressure

kgf/cm2

1.65

1.5

1.8

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

4.5

4.4

4.5

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

8

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

118.5

116.5

120.5

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

5+-0.5

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

10.2

7.2

13.2

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

134

129

139

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

975--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

925

Advance angle

deg.

0.3

Timer adjustment_03

Pump speed

r/min

1000

Advance angle

deg.

0.8

0.3

1.3

Timer adjustment_04

Pump speed

r/min

-

Advance angle

deg.

2.5

2.5

2.5

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

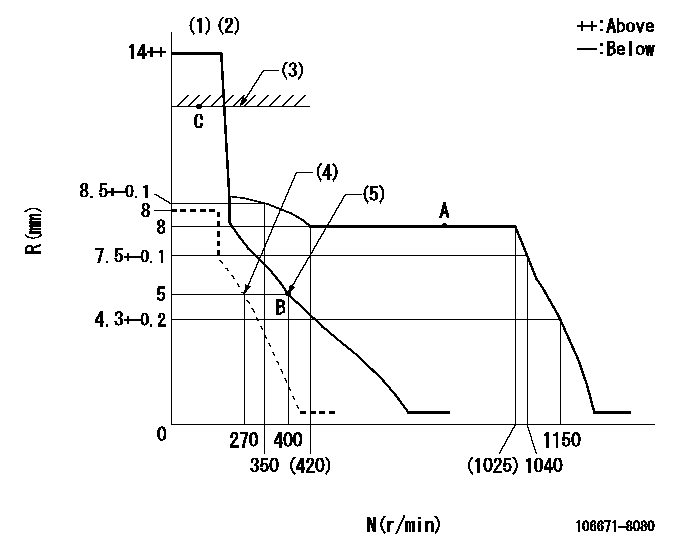

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Set idle sub-spring

(5)Main spring setting

----------

K=13

----------

----------

K=13

----------

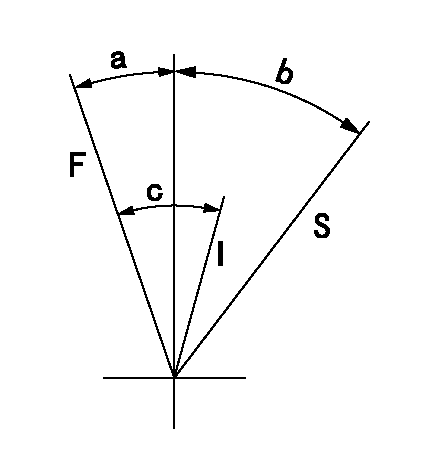

Speed control lever angle

F:Full speed

I:Idle

S:Stop

----------

----------

a=7deg+-5deg b=32deg+-3deg c=16deg+-5deg

----------

----------

a=7deg+-5deg b=32deg+-3deg c=16deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Normal

(2)Rack position aa or less, pump speed bb

----------

aa=4.5mm bb=0r/min

----------

a=27deg+-5deg b=53deg+-5deg

----------

aa=4.5mm bb=0r/min

----------

a=27deg+-5deg b=53deg+-5deg

0000001501 LEVER

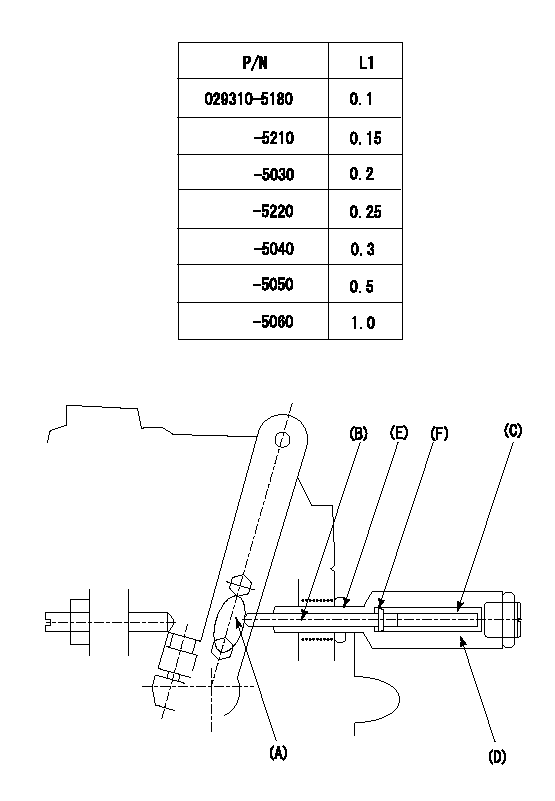

(F) P/N: Part number of the shim

L1:Thickness (mm)

1. Adjustment of the control lever

(1)Perform idling with the control lever (A) contacting the pushrod (B). At this time, confirm that the spring (C) is not compressed by control lever (A)'s operating torque.

(2)To set the stop position, compress spring (C) using the control lever (A) and adjust the rack so that it contacts the guide screw (D) at position L2. Then, set and fix using the lock nut (E). Adjust the rack position L2 at this time using the shim (F).

(3)Confirm that the control lever (A) returns to the idling position when pulled in the stop direction and then released.

----------

L2=0.2~2mm

----------

----------

L2=0.2~2mm

----------

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(40deg)

----------

----------

a=(40deg)

Information:

Cat Diesel Fuel Conditioner

Note: Cat Diesel Fuel Conditioner, part number 256-4968, is the only fuel conditioner/additive available to the end user that is tested and approved by Caterpillar for use in Caterpillar diesel engines.Cat Diesel Fuel Conditioner is a proprietary metal and ash free formulation that has been extensively tested for use with distillate diesel fuels for use in Caterpillar diesel engines. Cat Diesel Fuel Conditioner helps address many of the challenges that various fuels worldwide present in regards to fuel life/stability, engine startability, injector deposits, fuel system life, and long term engine performance.Note: Diesel fuel additives/conditioners may not improve markedly poor diesel fuel properties enough to make them acceptable for use.Note: For maximum overall benefits, ask your fuel supplier to add Cat Diesel Fuel Conditioner at the recommended treat rate before fuel delivery, or you may add Cat Diesel Fuel Conditioner at the recommended treat rate during the early weeks of fuel storage. Follow all applicable national, regional, and local laws, mandates, and regulations concerning the use of diesel fuel conditioners/additives.Cat Diesel Fuel Conditioner is a proven high performance, multipurpose diesel fuel conditioner that is designed to improve:

Fuel economy (through fuel system cleanup)

Lubricity

Oxidative stability

Detergency/dispersancy

Moisture dispersancy

Corrosion protection

Cetane (typically 2-3 cetane numbers)Cat Diesel Fuel Conditioner has been validated through lab and field tests to improve/reduce diesel fuel consumption and emissions for typical fleets through fuel system/injector cleanup, and to help maintain new engine performance by keeping fuel systems clean. Note that while fuel system/injector cleanup takes place over time, maintaining fuel system/injector cleanliness is an ongoing process.Data indicates that average fuel economy improvements across typical fleets may be in the 2-3+ percentage range. Note that improvements may vary based on factors such as engine model, age and condition of the engine, and application.Cat Diesel Fuel Conditioner also reduces the formation of gums, resins, and sludge, and disperses insoluble gums. This can dramatically improve fuel storage life, reduce fuel related engine deposits and corrosion, and extend fuel filter life.Note: Use of Cat Diesel Fuel Conditioner does not lessen the engine owner and/or fuel supplier responsibility to follow all industry standard maintenance practices for fuel storage and for fuel handling. Refer to the "General Fuel Information" article in this Special Publication for additional information. Additionally, use of Cat Diesel Fuel Conditioner does NOT lessen the engine owner responsibility to use appropriate diesel fuel. Refer to the "Fuel Specifications" section in this Special Publication (Maintenance Section) for guidance.Cat Diesel Fuel Conditioner is suitable for use with biodiesel/biodiesel blends that meet Caterpillar biodiesel recommendations and requirements. Note that not all fuel additives are suitable for use with biodiesel/biodiesel blends. Read and follow all applicable label usage instructions. Also, refer to this Special Publication, "Distillate Diesel Fuel" article, which includes Caterpillar biodiesel recommendations and requirements. Caterpillar strongly recommends the use of Cat Diesel Fuel Conditioner with biodiesel and biodiesel blends.When used as directed, Cat Diesel Fuel Conditioner has proven to be compatible with existing and U.S. EPA 2007 on-highway certified diesel engine emission control

Note: Cat Diesel Fuel Conditioner, part number 256-4968, is the only fuel conditioner/additive available to the end user that is tested and approved by Caterpillar for use in Caterpillar diesel engines.Cat Diesel Fuel Conditioner is a proprietary metal and ash free formulation that has been extensively tested for use with distillate diesel fuels for use in Caterpillar diesel engines. Cat Diesel Fuel Conditioner helps address many of the challenges that various fuels worldwide present in regards to fuel life/stability, engine startability, injector deposits, fuel system life, and long term engine performance.Note: Diesel fuel additives/conditioners may not improve markedly poor diesel fuel properties enough to make them acceptable for use.Note: For maximum overall benefits, ask your fuel supplier to add Cat Diesel Fuel Conditioner at the recommended treat rate before fuel delivery, or you may add Cat Diesel Fuel Conditioner at the recommended treat rate during the early weeks of fuel storage. Follow all applicable national, regional, and local laws, mandates, and regulations concerning the use of diesel fuel conditioners/additives.Cat Diesel Fuel Conditioner is a proven high performance, multipurpose diesel fuel conditioner that is designed to improve:

Fuel economy (through fuel system cleanup)

Lubricity

Oxidative stability

Detergency/dispersancy

Moisture dispersancy

Corrosion protection

Cetane (typically 2-3 cetane numbers)Cat Diesel Fuel Conditioner has been validated through lab and field tests to improve/reduce diesel fuel consumption and emissions for typical fleets through fuel system/injector cleanup, and to help maintain new engine performance by keeping fuel systems clean. Note that while fuel system/injector cleanup takes place over time, maintaining fuel system/injector cleanliness is an ongoing process.Data indicates that average fuel economy improvements across typical fleets may be in the 2-3+ percentage range. Note that improvements may vary based on factors such as engine model, age and condition of the engine, and application.Cat Diesel Fuel Conditioner also reduces the formation of gums, resins, and sludge, and disperses insoluble gums. This can dramatically improve fuel storage life, reduce fuel related engine deposits and corrosion, and extend fuel filter life.Note: Use of Cat Diesel Fuel Conditioner does not lessen the engine owner and/or fuel supplier responsibility to follow all industry standard maintenance practices for fuel storage and for fuel handling. Refer to the "General Fuel Information" article in this Special Publication for additional information. Additionally, use of Cat Diesel Fuel Conditioner does NOT lessen the engine owner responsibility to use appropriate diesel fuel. Refer to the "Fuel Specifications" section in this Special Publication (Maintenance Section) for guidance.Cat Diesel Fuel Conditioner is suitable for use with biodiesel/biodiesel blends that meet Caterpillar biodiesel recommendations and requirements. Note that not all fuel additives are suitable for use with biodiesel/biodiesel blends. Read and follow all applicable label usage instructions. Also, refer to this Special Publication, "Distillate Diesel Fuel" article, which includes Caterpillar biodiesel recommendations and requirements. Caterpillar strongly recommends the use of Cat Diesel Fuel Conditioner with biodiesel and biodiesel blends.When used as directed, Cat Diesel Fuel Conditioner has proven to be compatible with existing and U.S. EPA 2007 on-highway certified diesel engine emission control