Information injection-pump assembly

ZEXEL

106671-8060

1066718060

Rating:

Cross reference number

ZEXEL

106671-8060

1066718060

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8130

Bosch type code

EFEP215A

Nozzle

105780-0050

Bosch type code

DN6TD119NP1T

Nozzle holder

105780-2090

Bosch type code

EFEP215

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

134424-3620

Overflow valve opening pressure

kPa

162

147

177

Overflow valve opening pressure

kgf/cm2

1.65

1.5

1.8

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

4.5

4.44

4.5

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.75 60.25

Cal 1-4 deg. 60 59.75 60.25

Difference between angles 2

Cyl.1-2 deg. 120 119.75 120.25

Cyl.1-2 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cal 1-3 deg. 240 239.75 240.25

Cal 1-3 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-5 deg. 300 299.75 300.25

Cal 1-5 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

A

Rack position

10.6

Pump speed

r/min

1150

1150

1150

Average injection quantity

mm3/st.

302.8

300.8

304.8

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

3.9+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

14.5

11.5

17.5

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

218

213

223

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

(975)--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

(925)

Advance angle

deg.

0.3

Timer adjustment_03

Pump speed

r/min

1150

Advance angle

deg.

2.5

2

3

Remarks

Finish

Finish

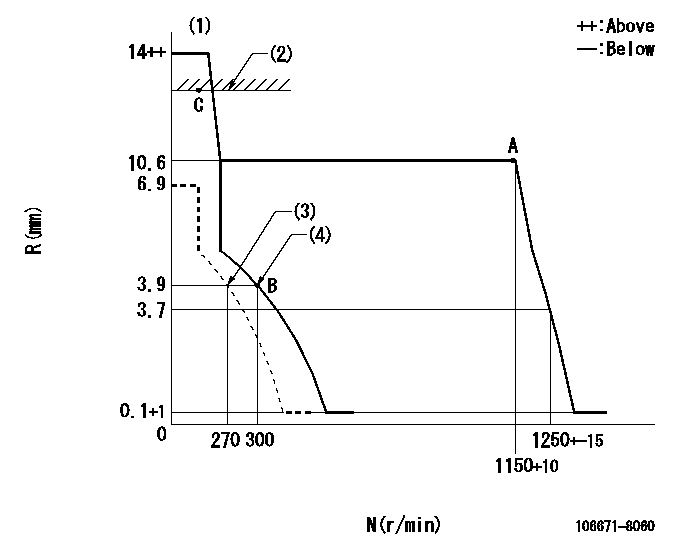

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)RACK LIMIT

(3)Set idle sub-spring

(4)Main spring setting

----------

K=7

----------

----------

K=7

----------

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=6deg+-5deg b=29deg+-5deg

----------

----------

a=6deg+-5deg b=29deg+-5deg

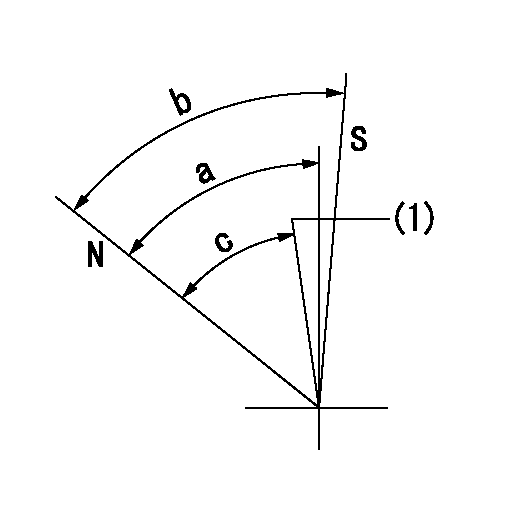

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Confirm that it returns to the non-injection position (N = aa).

----------

aa=300r/min

----------

a=53deg+-5deg b=53deg+-5deg c=49deg

----------

aa=300r/min

----------

a=53deg+-5deg b=53deg+-5deg c=49deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(40deg)

----------

----------

a=(40deg)

Information:

Introduction

The permanent solution for the problem that is identified below is not known. Until the permanent solution is known, use the solution that is identified below.Problem

The above listed serial numbers have had issues with metal shavings in the Hydraulic Electronic Unit Injector (HEUI) oil passages. These shavings were left in the HEUI oil passages as a result of a nozzle that was not operating correctly.Solution

Return 0R-8849 Cylinder Head Gp with date codes 09006 through date code 12006. Return the 0R-7907 Cylinder Block Gp with the following sequence numbers.

Table 1

Sequence Numbers

01650 01649 01648 01647 01646

01645 01644 01642 01641 01636

01635 01630 01628 01627 01626

01625 01618 01617 01614 01613

01610 01609 01608 01607 01606

01605 01603 01602 01600 01599

01598 01597 01595 01592 Note: If cylinder blocks or cylinder heads have been installed, do not replace the cylinder heads. Instead, flush the HEUI oil system and replace all of the fuel injectors.

The permanent solution for the problem that is identified below is not known. Until the permanent solution is known, use the solution that is identified below.Problem

The above listed serial numbers have had issues with metal shavings in the Hydraulic Electronic Unit Injector (HEUI) oil passages. These shavings were left in the HEUI oil passages as a result of a nozzle that was not operating correctly.Solution

Return 0R-8849 Cylinder Head Gp with date codes 09006 through date code 12006. Return the 0R-7907 Cylinder Block Gp with the following sequence numbers.

Table 1

Sequence Numbers

01650 01649 01648 01647 01646

01645 01644 01642 01641 01636

01635 01630 01628 01627 01626

01625 01618 01617 01614 01613

01610 01609 01608 01607 01606

01605 01603 01602 01600 01599

01598 01597 01595 01592 Note: If cylinder blocks or cylinder heads have been installed, do not replace the cylinder heads. Instead, flush the HEUI oil system and replace all of the fuel injectors.