Information injection-pump assembly

BOSCH

9 400 616 960

9400616960

ZEXEL

106671-7900

1066717900

MITSUBISHI

ME050867

me050867

Rating:

Service parts 106671-7900 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

ME059740

12.

Open Pre:MPa(Kqf/cm2)

21.6(220)

15.

NOZZLE SET

Include in #1:

106671-7900

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 616 960

9400616960

ZEXEL

106671-7900

1066717900

MITSUBISHI

ME050867

me050867

Zexel num

Bosch num

Firm num

Name

106671-7900

9 400 616 960

ME050867 MITSUBISHI

INJECTION-PUMP ASSEMBLY

6D22TC * K

6D22TC * K

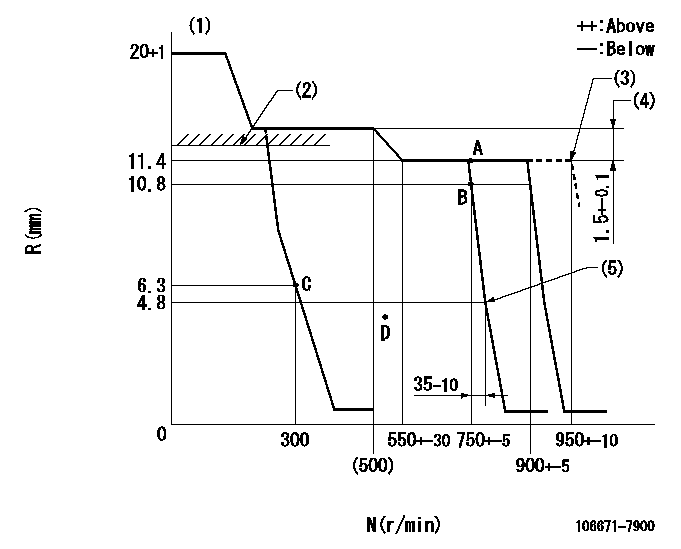

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-4620

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.8

4.75

4.85

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

11.4

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

154.7

151.7

157.7

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

10.8

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

137.9

134.9

140.9

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

6.3+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

11.2

8.6

13.8

Fixing the rack

*

Remarks

(check)

(check)

Injection quantity adjustment_04

Adjusting point

D

Rack position

5.5+-0.5

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

10.2

7.6

12.8

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Timer adjustment

Pump speed

r/min

900++

Advance angle

deg.

0

0

0

Remarks

Do not advance until starting N = 900.

Do not advance until starting N = 900.

Timer adjustment_02

Pump speed

r/min

900

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

-

Advance angle

deg.

1.5

1.5

1.5

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)RACK LIMIT: RAL

(3)At shipping

(4)Rack difference between N = N1 and N = N2

(5)Idle sub spring setting: L1.

----------

K=6 RAL=11.7+0.2mm N1=750r/min N2=450r/min L1=4.3+-0.1mm

----------

----------

K=6 RAL=11.7+0.2mm N1=750r/min N2=450r/min L1=4.3+-0.1mm

----------

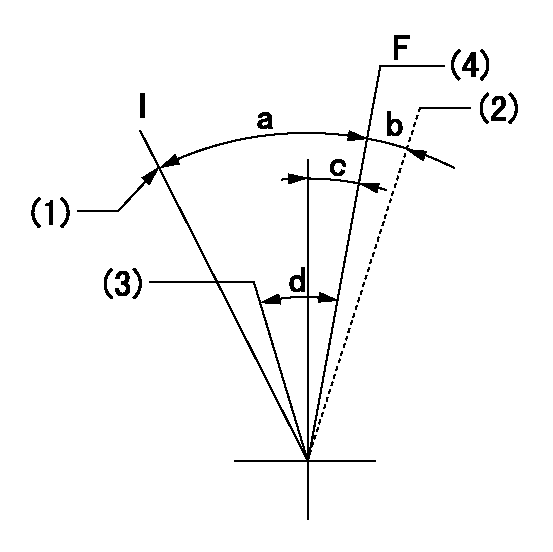

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

(2)At shipping

(3)Pump speed = aa

(4)Pump speed = bb

----------

aa=750r/min bb=900r/min

----------

a=(25deg)+-5deg b=(2deg) c=(0deg)+-5deg d=(7deg)+-5deg

----------

aa=750r/min bb=900r/min

----------

a=(25deg)+-5deg b=(2deg) c=(0deg)+-5deg d=(7deg)+-5deg

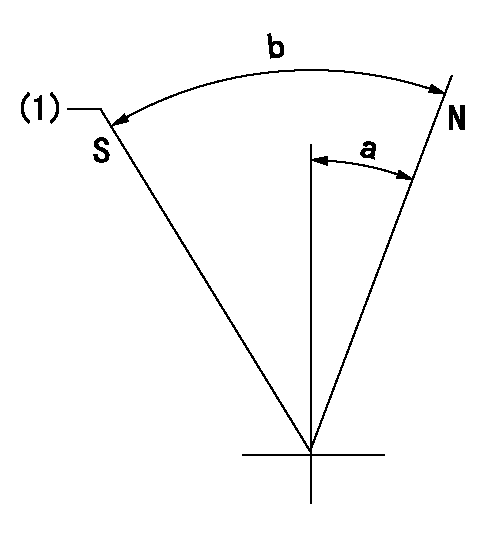

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)At shipping

----------

----------

a=39deg+-5deg b=53deg+-5deg

----------

----------

a=39deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(7deg)

----------

----------

a=(7deg)

Information:

Introduction

Do not perform any procedure in this Special Instruction until you read this information and you understand this information.This Special Instruction provides the following information for 3600 Diesel Engines:

Identification of a service tool

A procedure to check cylinder pressureService Tool

Illustration 1 g01250874

4C-6585 Indicator Group (1) Hand tool for tightening gauge connectionProcedure for Checking Cylinder Pressure

Take the readings for cylinder pressure at the rated speed and at the rated load in order to obtain the peak cylinder pressure for a specific rating.Readings for cylinder pressure can also be taken at a light load condition or at a no-load condition. These pressure readings can be used as a baseline for a comparison at a later date. For a valid comparison, pressure measurements that are taken at a later date must duplicate the initial load conditions.

Illustration 2 g01250892

(2) Cylinder pressure valve (Kiene valve) (3) Valve stem (4) Cap

Remove cap (4) from valve (2) .

Fluids may escape from the cylinder pressure valves at high velocity during this procedure and cause personal injury. Always stay clear and keep personnel away from the cylinder pressure valves during this procedure.

Stand to the side of the valve and open valve stem (3) approximately 90° (1/4 turn) counterclockwise. Close valve stem (3). This will blow any foreign debris out of the valve.

Illustration 3 g01250917

(5) 4C-9736 Pressure Gauge (6) 4C-9737 Gauge connection

Install the 4C-6585 Indicator group on the valve. Use tool (1) that is provided in the indicator group in order to tighten gauge connection (6) to a torque of 17 3 N m (12 2 lb ft). Do not overtighten the gauge connection.

Open valve stem (3) by approximately 540° (1 1/2 turn) counterclockwise. Document the reading on pressure gauge (5) and close valve stem (3). Tighten the valve stem to a torque of 24 3 N m (18 2 lb ft). Do not overtighten the valve stem.

Use the hand tool that is provided in the indicator group in order to loosen the gauge connection. Remove the 4C-6585 Indicator Group .

Install cap (4). Tighten to a torque of 17 3 N m (12 2 lb ft). Do not overtighten the cap.

Do not perform any procedure in this Special Instruction until you read this information and you understand this information.This Special Instruction provides the following information for 3600 Diesel Engines:

Identification of a service tool

A procedure to check cylinder pressureService Tool

Illustration 1 g01250874

4C-6585 Indicator Group (1) Hand tool for tightening gauge connectionProcedure for Checking Cylinder Pressure

Take the readings for cylinder pressure at the rated speed and at the rated load in order to obtain the peak cylinder pressure for a specific rating.Readings for cylinder pressure can also be taken at a light load condition or at a no-load condition. These pressure readings can be used as a baseline for a comparison at a later date. For a valid comparison, pressure measurements that are taken at a later date must duplicate the initial load conditions.

Illustration 2 g01250892

(2) Cylinder pressure valve (Kiene valve) (3) Valve stem (4) Cap

Remove cap (4) from valve (2) .

Fluids may escape from the cylinder pressure valves at high velocity during this procedure and cause personal injury. Always stay clear and keep personnel away from the cylinder pressure valves during this procedure.

Stand to the side of the valve and open valve stem (3) approximately 90° (1/4 turn) counterclockwise. Close valve stem (3). This will blow any foreign debris out of the valve.

Illustration 3 g01250917

(5) 4C-9736 Pressure Gauge (6) 4C-9737 Gauge connection

Install the 4C-6585 Indicator group on the valve. Use tool (1) that is provided in the indicator group in order to tighten gauge connection (6) to a torque of 17 3 N m (12 2 lb ft). Do not overtighten the gauge connection.

Open valve stem (3) by approximately 540° (1 1/2 turn) counterclockwise. Document the reading on pressure gauge (5) and close valve stem (3). Tighten the valve stem to a torque of 24 3 N m (18 2 lb ft). Do not overtighten the valve stem.

Use the hand tool that is provided in the indicator group in order to loosen the gauge connection. Remove the 4C-6585 Indicator Group .

Install cap (4). Tighten to a torque of 17 3 N m (12 2 lb ft). Do not overtighten the cap.

Have questions with 106671-7900?

Group cross 106671-7900 ZEXEL

Mitsubishi

106671-7900

9 400 616 960

ME050867

INJECTION-PUMP ASSEMBLY

6D22TC

6D22TC